nonon

August 25, 2023, 12:18pm

1

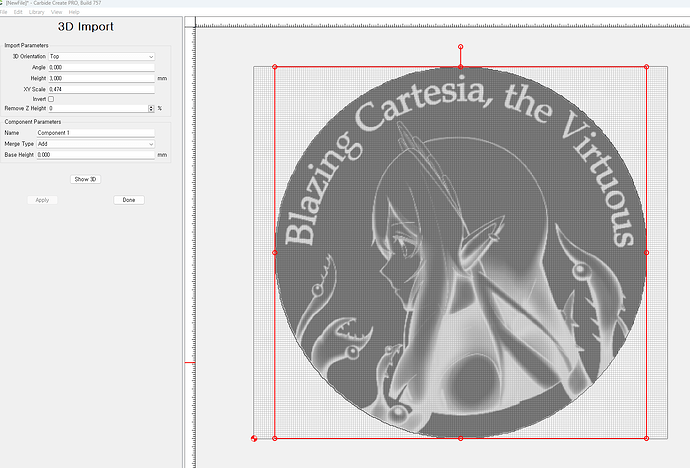

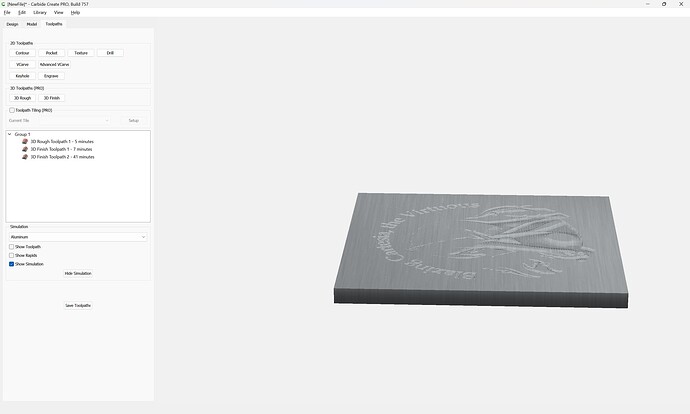

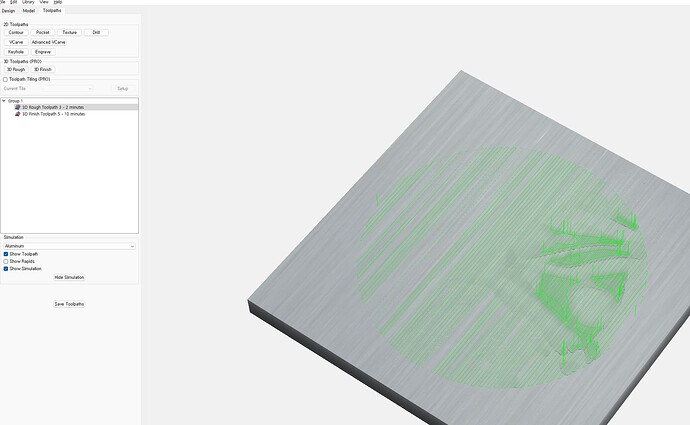

first, i imprt my 3d stl file.

i thought that looks cool.

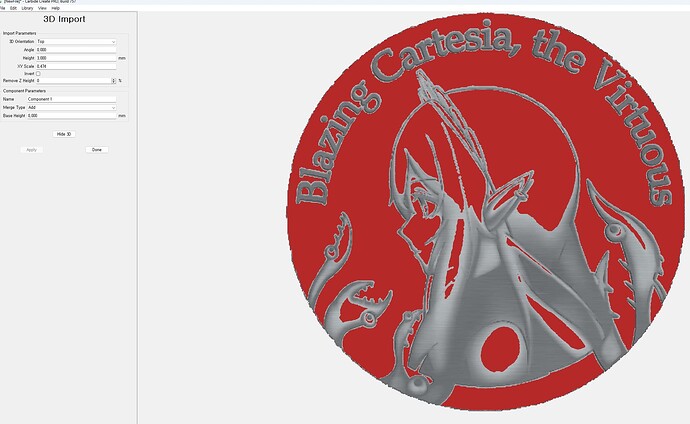

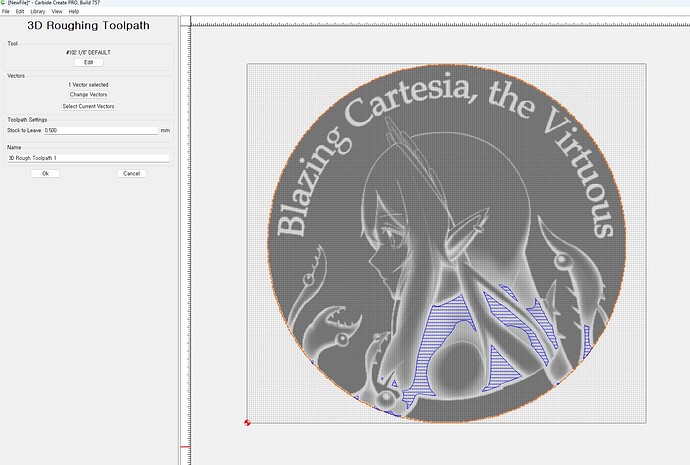

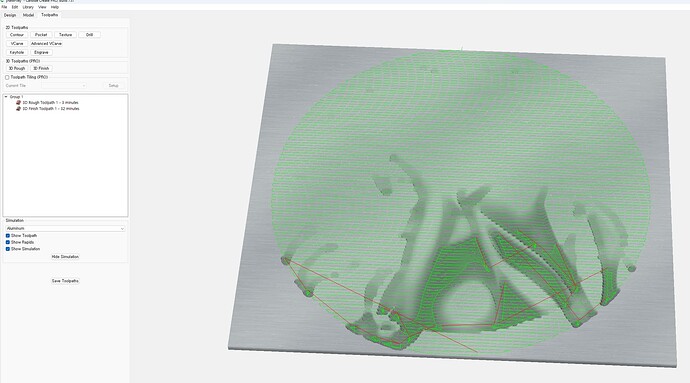

i try rough 3d and

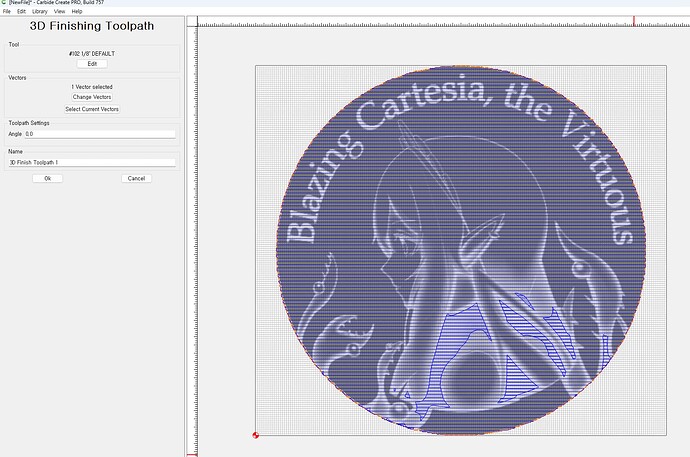

did finish 3d.

but expect result is very bad.

It’s a completely different result compared to when I saw the imported image in advance.

Is there a tutorial or video that I can get help with on this? I’m at a loss.

WillAdams

August 25, 2023, 12:49pm

2

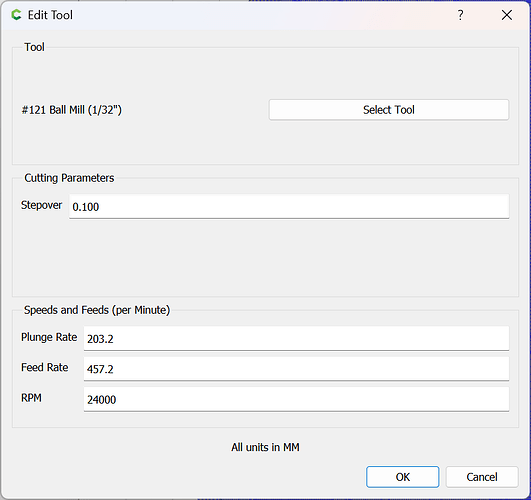

The red indicates that you are raising the model up above the Stock thickness.

I suspect you may want to invert the image.

Could you post your files? Both .c2d and .stl? (send them to projects@carbide3d.com if not suited for sharing)

nonon

August 25, 2023, 1:03pm

3

I invert it, but the result was not much different. i sent stl file to ur email. thx for taking time for me

Let us know how this turns out, looks really interesting

1 Like

WillAdams

August 25, 2023, 10:27pm

5

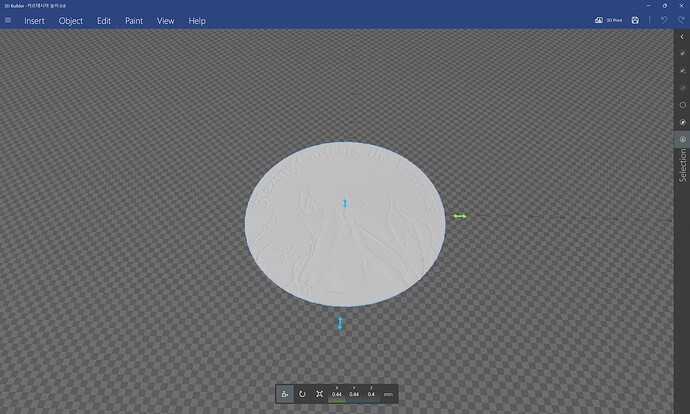

The file seems quite physically small, and does not seem to have much in the way of Z variation:

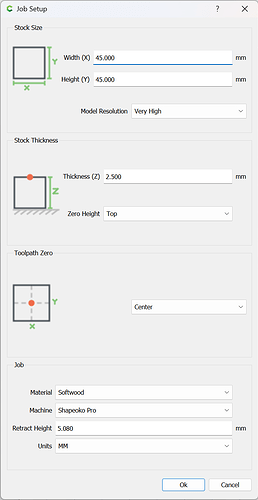

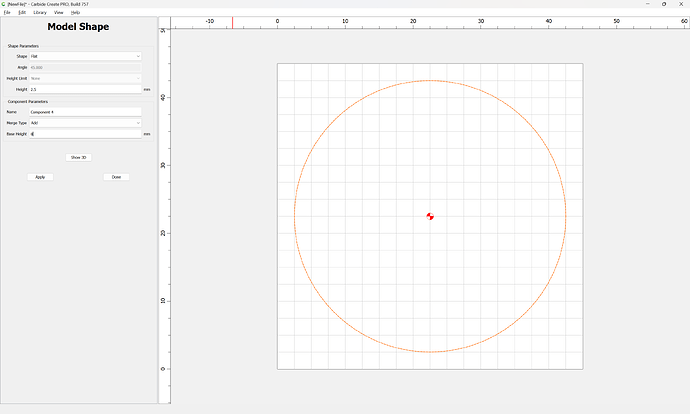

Checking on Amazon most coin blanks seem to be 40mm in diameter and 2.5mm thick, so we set up the file for that:

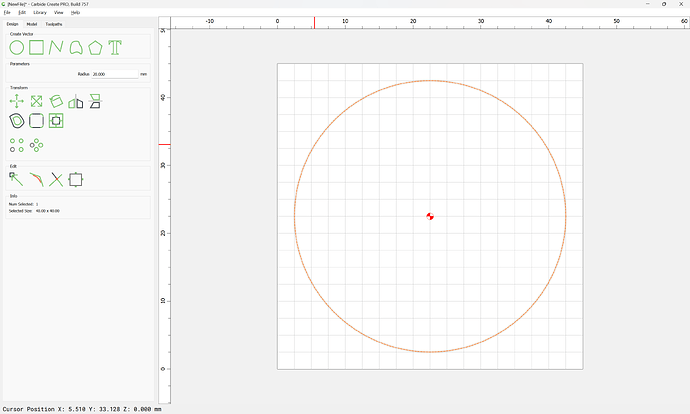

We then draw in a circle for the blank:

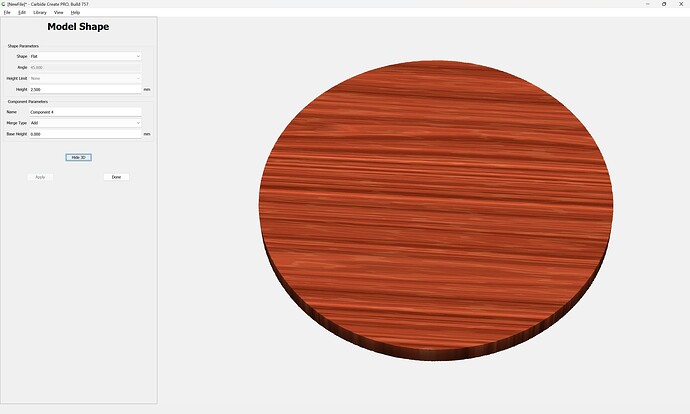

Model the stock:

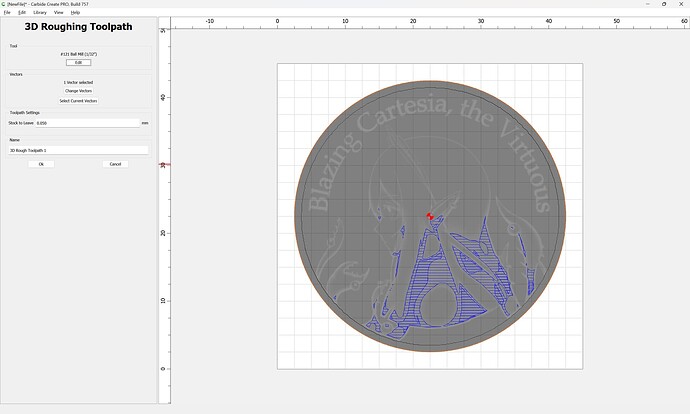

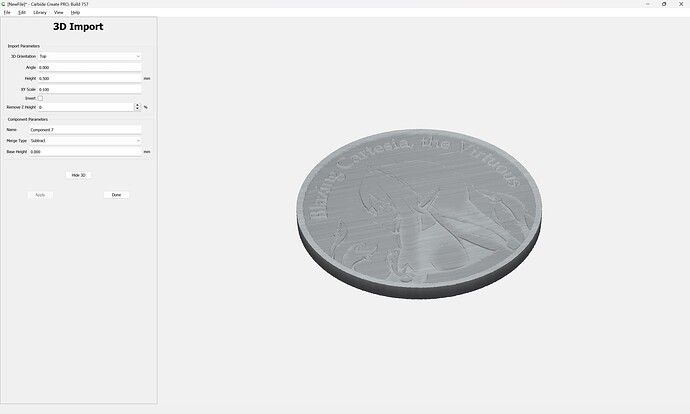

and import the STL:

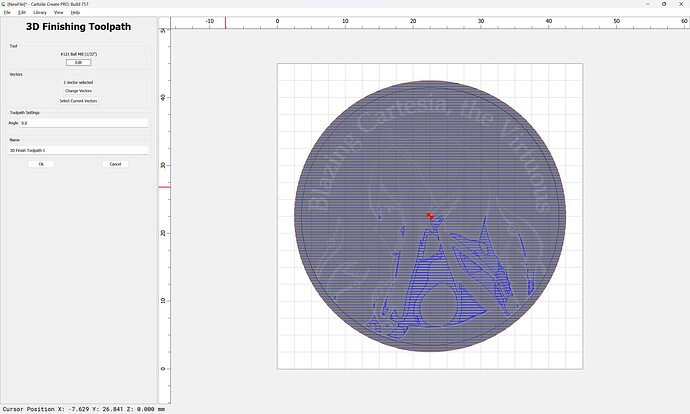

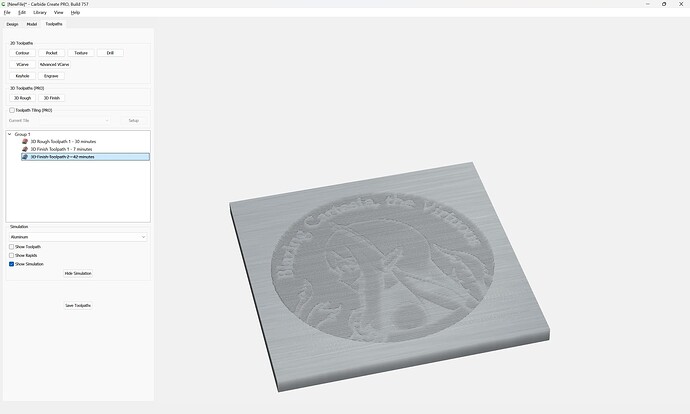

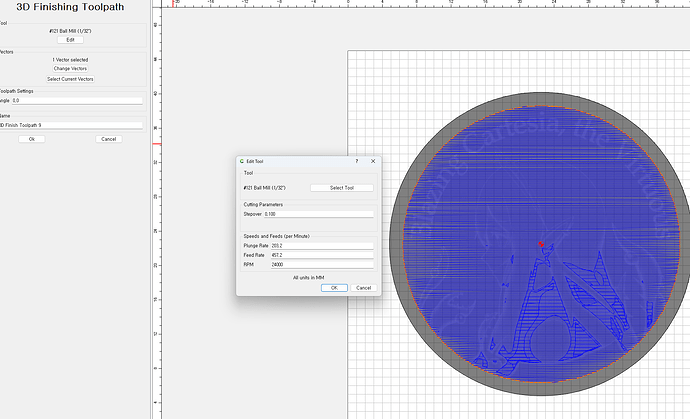

We then apply 3D roughing and finishing toolpaths using suitable small tools:

If you create an impossibly small tool you can get:

Subtracting the STL we instead get:

which previews as:

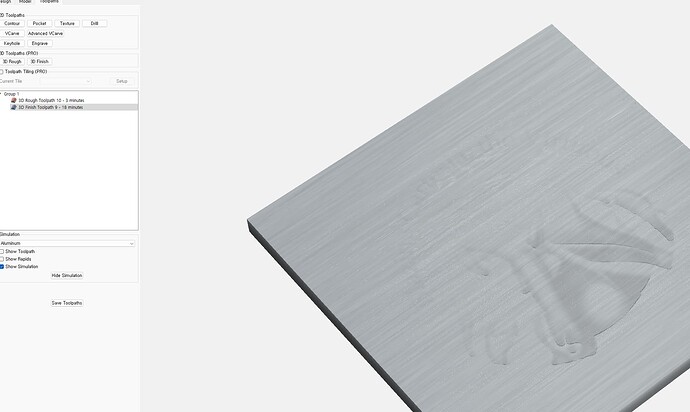

Adding more 3D Finishing toolpaths and increasing stepover gets us to:

nonon

August 25, 2023, 10:38pm

6

Thanks to you, I understood more about how to apply the stl file. Very kind and detailed! thx a lot. I’ll update you when the results come out

nonon

August 26, 2023, 9:54am

7

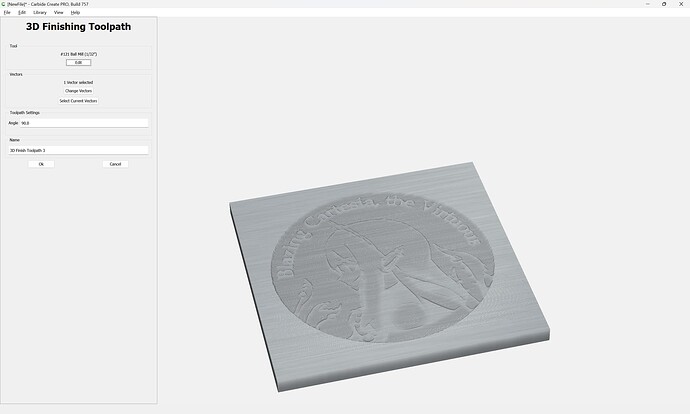

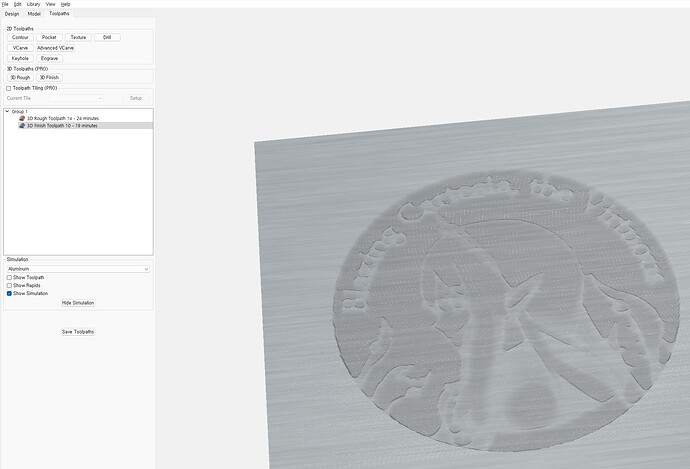

hi! i did modeling with ur screen shot. but simulated result is very different. can i know the problem? // i find ur third toolpath. what is that?

WillAdams

August 26, 2023, 1:05pm

8

I posted the screen grabs above with my specific settings — please try those.

The disabled toolpath was a test w/ an impossibly small tool to see how the initial 3D model would cut.

nonon

August 26, 2023, 2:10pm

9

where can i saw ur post? I did it the same as the setting you sent me above. I sent you a video of my process by email. Could you check it out?

WillAdams

August 26, 2023, 2:30pm

10

As noted above, the stepover was adjusted.

nonon

August 26, 2023, 2:35pm

11

the result has slight changed. but still bad .

WillAdams

August 26, 2023, 2:36pm

12

I believe I had better luck subtracting the STL from the design — see the screen grabs in my post above.

nonon

August 27, 2023, 7:18am

13

I made a simulation with subtracting. It’s better than before, but it’s not clear, what do you think

WillAdams

August 27, 2023, 2:11pm

14

This may become clearer with smaller tooling which can cut better details.

Or, perhaps you could get, or make a better 3D model.

Or, perhaps you could re-draw some of the design in Carbide Create so as to better cut the details.

nonon

August 27, 2023, 2:23pm

15

i see. but i use same tool #121 and same design file. but simulated result is quite different. i don’t know what is different

WillAdams

August 27, 2023, 2:30pm

16

Cutting a design into a surface (incised) and cutting a design away from a surface (bas relief) are quite different things, and the same tool used for each may have different results depending on the specifics of the details.

nonon

August 27, 2023, 2:42pm

17

Can I follow ur detailed settings? I copied the images you sent me, but there must be something else. I’m sorry I took up too much of your time.

WillAdams

August 27, 2023, 2:48pm

18

Yes, I posted screen grabs of every step I went through in making the file which I sent to you — one thing which I would suggest is to copy into the component name all of the settings used for a given component — that should allow experimentation, and evaluation of how one setting differs from another.

I wrote a little bit about Carbide Create Pro’s 3D modeling at:

which will hopefully be helpful.

And there are of course the videos at:

https://my.carbide3d.com/#Carbide_Create_Pro

If you need more, I would suggest signing up for a training class:

Whether you're a beginner or an experienced craftsman, this personalized training experience will accelerate your skills and understanding of your Nomad or Shapeoko and its associated software. Dive into the world of Carbide Create design software,...

Price: USD 30.00

1 Like

system

September 24, 2023, 12:18pm

20

This topic was automatically closed after 30 days. New replies are no longer allowed.