If one wants to make drawers which are:

21.846" wide, 18" deep, 10" high

out of:

1/2" Baltic Birch

using a:

1/4 compression bit

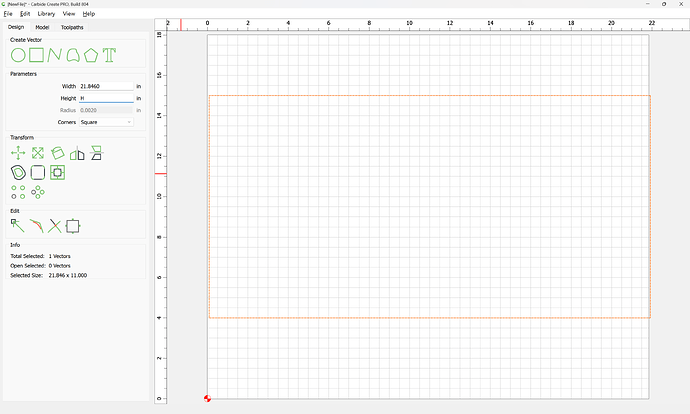

One approach would be:

which gives us the overall dimensions along X and Y.

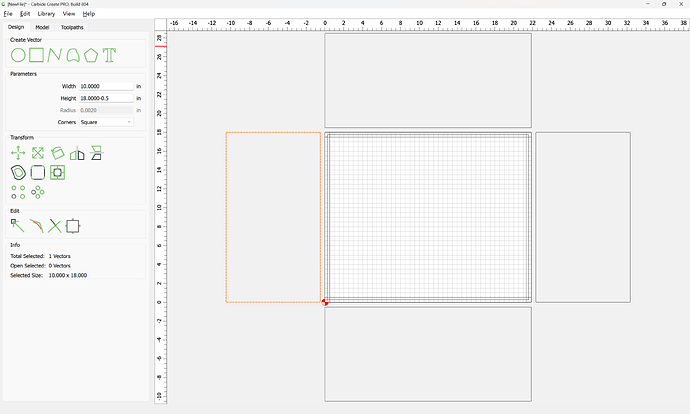

We then draw in the sides, front, and back as seen from overhead:

and then select the original geometry:

and subtract the Stock Thickness from the Width and Height:

which gives us the dimensions of the bottom.

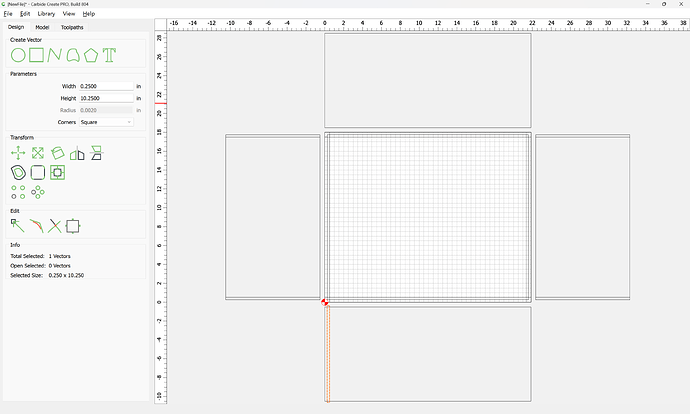

Then, draw in the profiles of the sides, front, and back:

and draw in a vertical view of the joinery:

and adjust the size of the sides to match that size:

Dupe the sides and re-size them to match the extent of the material left behind by the rabbet:

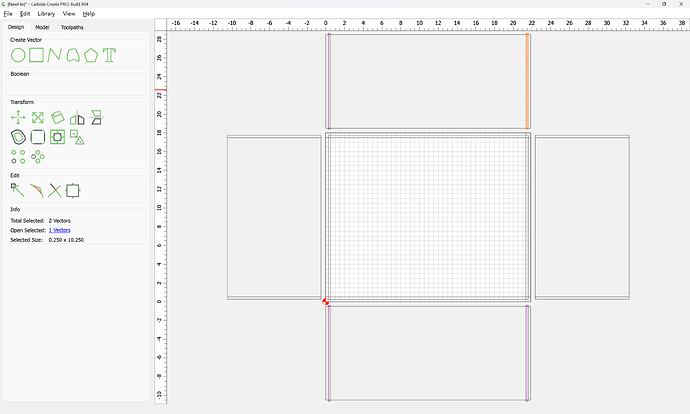

and draw in the geometry for the rabbets:

Since the tool being used is the same dimension as the desired rabbet, draw in lines:

and position them at the center of each rectangle which demarcates the rabbet:

using Align:

It will also be necessary to draw in geometry which defines the grooves for the bottom:

Note that there are two ways to handle this — just cut the groove as a pocket, or use it to delineate two separate islands which will be left proud — we will do the latter:

OK

Done

Next, arrange all the parts on a sheet:

delete the unneeded geometry:

and re-arrange parts for a reasonably efficient usage of the sheet, being careful to position the pieces separated by at least endmill diameter plus 10%.

(if desired, flip parts for a consistent placement which will make workholding easier and may make cutting more efficient)

Select all the geometry which defines the parts:

and offset by endmill diameter plus 10%:

Apply

At this point, toolpaths may be applied:

Select the open geometry:

and apply a No Offset Contour toolpath to half the thickness:

Then select all the geometry which defines the interior surfaces of the drawer as well as the surrounding offset geometry:

and assign a Pocket toolpath to half the depth:

Then select the geometry which defines the perimeter of all the parts and the surrounding offset geometry:

and assign a pocket toolpath which starts at the bottom of the previous pocket and cuts down to tab height:

Go back to the Design tab, and remove the outer offset geometry from the selection:

and edit tabs:

adding a reasonable number of tabs, being careful to align them where necessary so that opposing parts will have tabs in the same location:

Note that it will be necessary to zoom in to place the second of a pair of tabs:

Assign an Outside Contour toolpath which starts at the bottom of the previous pocket:

Verifying the 3D preview:

we do see one point of improvement — the groove unnecessarily shows at the sides, so we draw in 1/4" wide rectangles:

and Boolean Union them with the geometry for the front/back interior features:

OK

OK

If need be, adjust to ensure that the updated geometry is associated with the toolpaths.

Attached as a v8 file:

drawer_21_846x18x10_v8.c2d (84 KB)

Note that the above dimensions and toolpaths should be tested in a piece of scrap, and adjusted for fit, runout, &c. and may require calibration on a belt-drive machine.