Hello, I’m trying to cut some gears for a wooden clock in 6mm birch plywood and am getting lots of chipping of the edge and tear outs of the top ply. I have polyurethaned both sides to make it tougher but haven’t tried painters tape yet. Is it possible to program a contour path that takes increasing DOC i.e. 1st cut .5mm 2nd cut 1mm and so on in one file or do I need to combine several files. My original F&S are 2mm 2 flute uncut (waiting on some compression bits to arrive) 6000rpm 2000mm/m and 2mm DOC.

Cheers

Mike

I don’t know what software you’re using, but in Vcarve, you set the depth per pass for the bit and the software will generate how ever many paths are required to get to the total cut depth. I assume this same functionality is in Carbide Create - just set the depth per pass as small or large as you want.

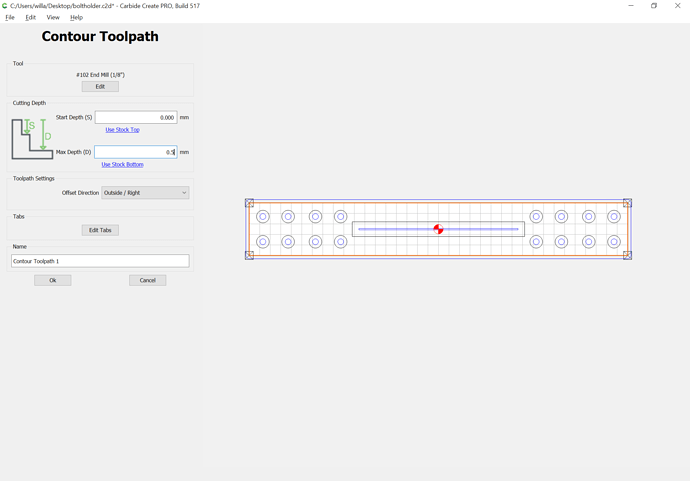

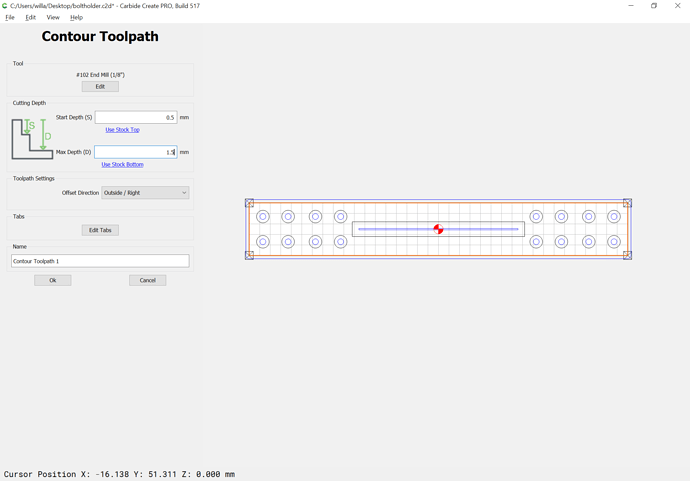

This could be done, but it would require one toolpath per pass:

&c.

and the tool would have to have its depth per pass set to a sufficiently deep cut that it would make each in a single pass.

You could also create a custom tool and set the depth of cut to what ever you want. I saw you mentioned you are waiting on a compression bit. I do not think this will help you. Compression bits are designed to take a full depth cut. This full depth cut has up cut on the bottom and down cut at the top and the middle is something in between. The compression bit works fine on large 3HP routers and on industrial cnc machines that much more power to go thicker material.

You might be able to get your Shapeoko to do this but due to the limitations of the router HP and the nature of belts you might get too much strain on your machine. Search for compression bits on the forum to get a taste of what people have tried to do.

Baltic birch plywood varies in quality and the top veneer is usually quite thin leading to your chip out. So try using a down cut bit half way through the plywood and create another tool path using an upcut bit to finish the cut out around your gear. Even that may not guarantee no chip out on baltic birch.

Thanks for all the replies, I have a homebuilt machine ( I frequent this forum for the great information and people is has) with a 1.5KW spindle so I don’t think that’s a problem, what I was really hoping for was something in fusion that would do the increasing steps in one file but it looks like I’ll hav to try combining several files with different step-downs and rest machining.

Cheers

Mike

This topic was automatically closed after 10 days. New replies are no longer allowed.