This was prompted by another thread about permanent fixture plates. I was thinking about marking such fixtures with a barcode. Could there be some kind of Carbide Motion integration to a scanner recall files, origin point, feeds and speeds notes. Just dreaming out loud. Thanks Joe C

I think you could do this sort of integration by having a shortcut program which has a list of the barcodes and their matching commands which it then plays back to Carbide Motion — this isn’t something which we can support though.

You might want to look into other tools such as bCNC which are programmable.

I absolutely love this idea.

In a truly serendipitous turn of events, I’ve got an industrial barcode scanner and a fiber laser on the way already. They are for various other projects buuuut…I know what my first project is going to be now ![]()

I’ll make sure to post about how it works when I get around to it ![]()

Not a “barcode.” Use a QR code. You might be able to store all of your data within the code.

Unless you have an automated way to use the data, you might as well just etch the data on the fixture & save yourself the step of scanning it before entering the data.

Or as Well mentioned, create macros to set the parameters & you could just number the fixtures.

i.e. Fixture_Macro_1…

But how can I overly complicate the situation?! Generally, i will make notes on scraps of paper and then loose that paper. I think your suggestion wins the day. Thanks. - Joe C.

You mean to tell me you don’t want to integrate your CNC into your home assistant ecosystem ![]()

Well suit yourself, I’m trying it regardless ![]() (it’s going to go poorly and end in frustration… but I’m ok with that

(it’s going to go poorly and end in frustration… but I’m ok with that ![]() )

)

Alexa, start my CNC and load job123.C2D

Bonus if she can mount the stock and zero it.

Automation is achieved in stages, one foot in front of the other and before you know it… you’re bored and looking for the next thing to automate ![]()

I have most of my lights and some of my dust collection done. If only I could automate getting the kids ready for bed. Or better yet, automate my real job (without the boss knowing) so that I could spend more time in the workshop.

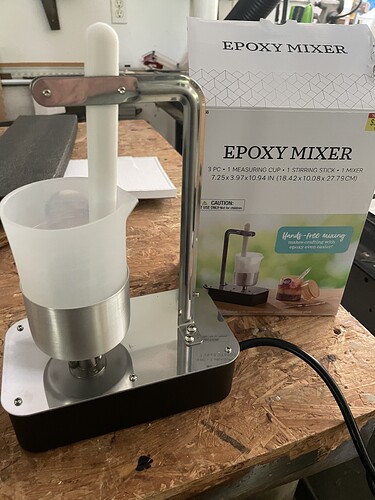

Speaking of automation, I just bought this and used it last night.

It seems like a dumb thing but it was pretty nice and did a good job of being consistent in the mixing while I could do other things. Makes it easier to do a thorough job mixing as opposed to me getting bored and rushing it.

Every time you turn it on the direction changes for the previous one. So, I would occasionally turn it off and back on.

It’s not so dumb. It’s a bit much for mixing a spot of epoxy to patch your reading glasses but i had a friend who was mixing alot of epoxy to cover a table top. I tried to help, but was chastised for whipping too much air and bubbles in to the epoxy. It would be handy there.

I generally just take a wooden tongue depressor and chuck it in my drill and go crazy.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.