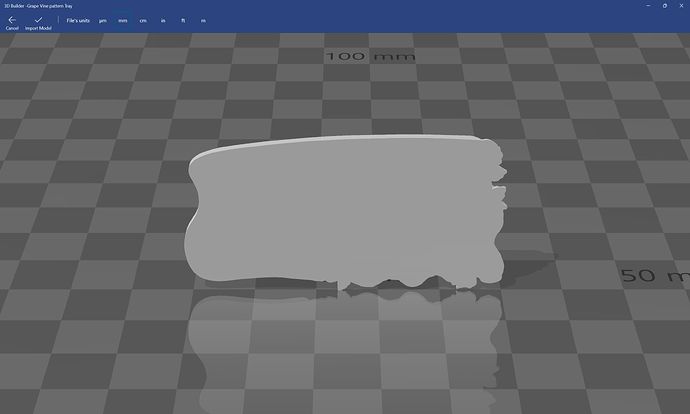

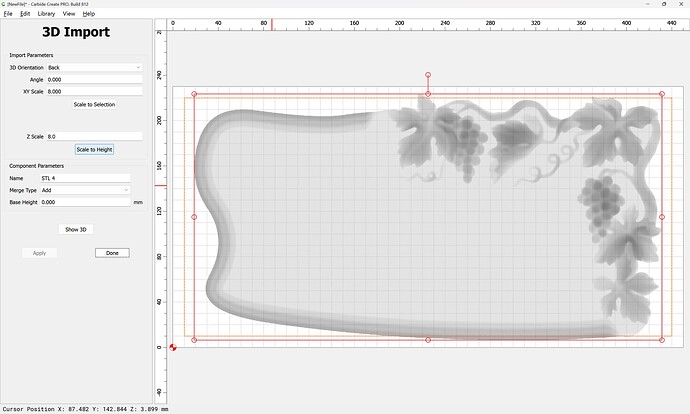

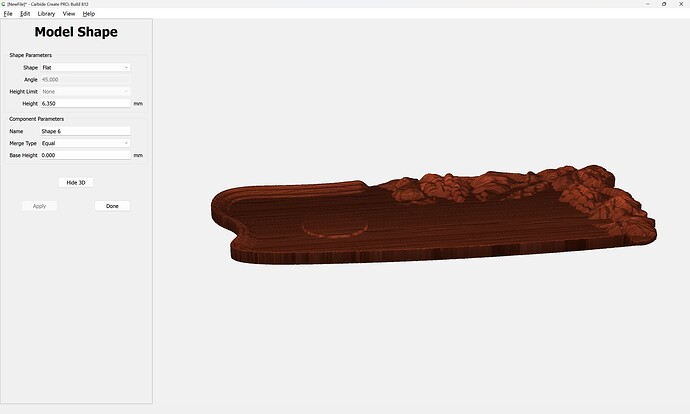

Given an STL file:

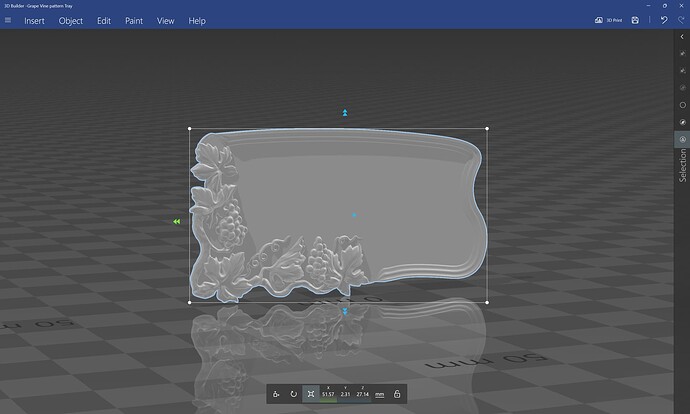

which once opened and imported is:

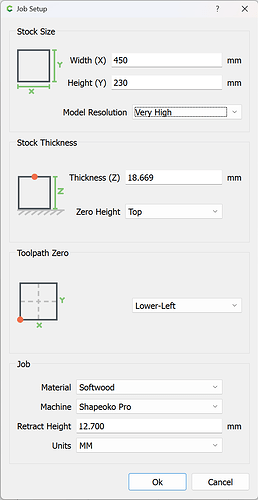

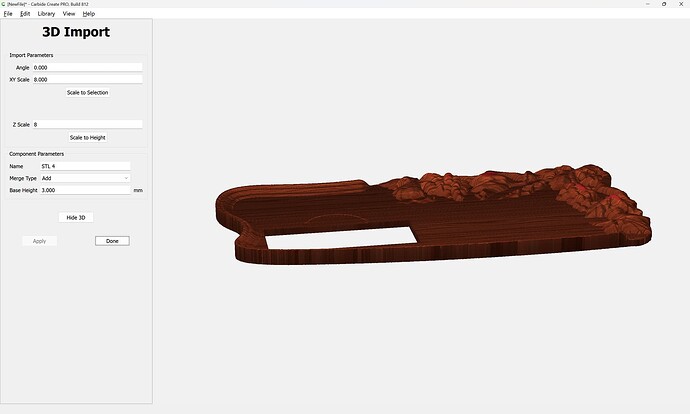

Stock thickness is noted as:

wood is .735" thick, I am wanting a .25 bottom Base.

There are three different ways to approach this, but we will assume that the desire is for a serving tray which has a working thickness of 0.25", and which uses the full thickness of the stock.

2.31mm == 0.09094488

so the model will need to be scaled up quite a bit (x8)

Rounding up a bit we arrive at:

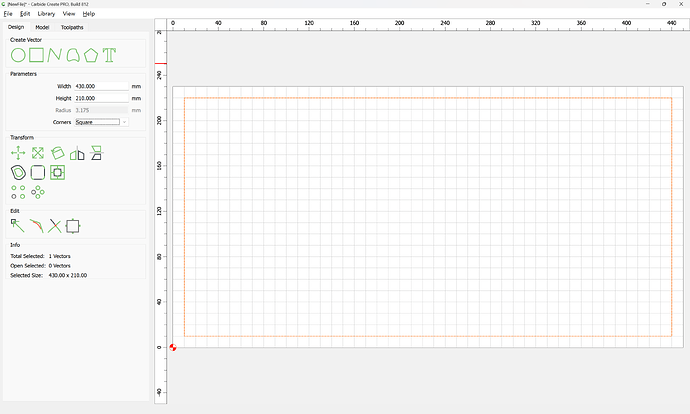

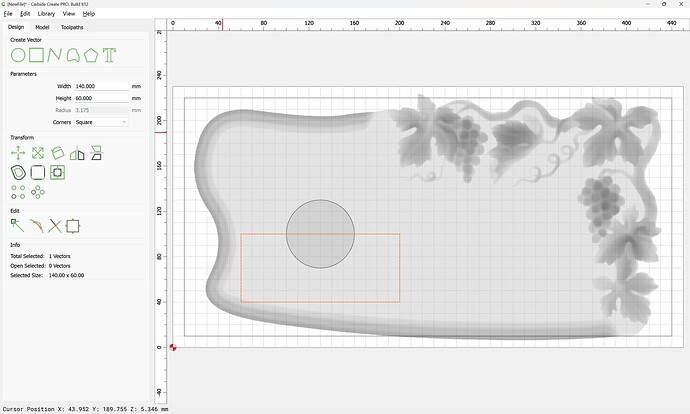

so we draw:

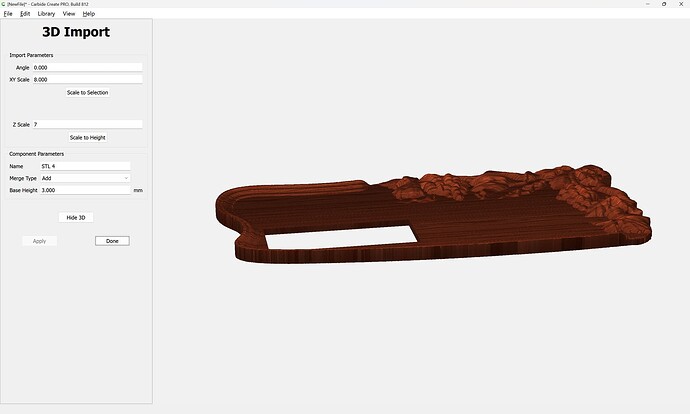

and import:

adjusting parameters as desired.

Done

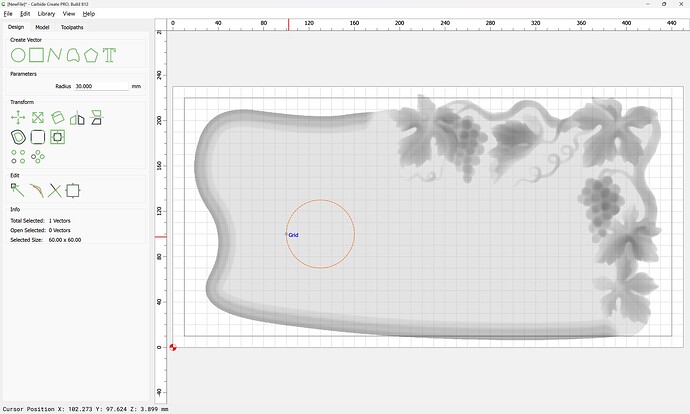

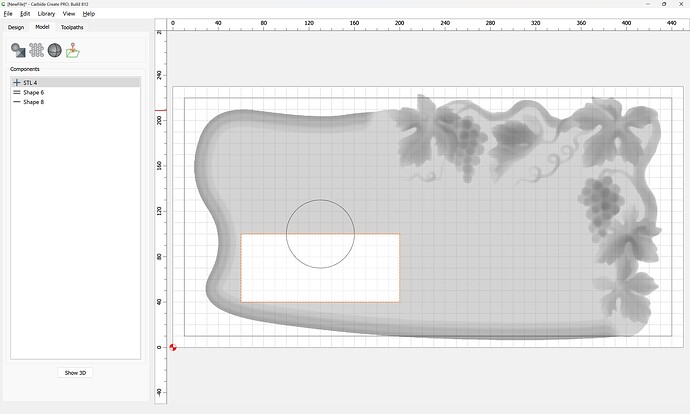

We then draw in a bit of geometry in the base area:

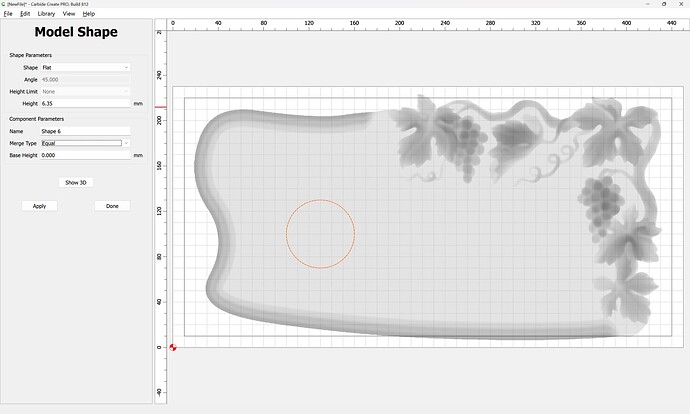

and model it to be 0.25" thick:

which shows that some additional thickness will need to be added.

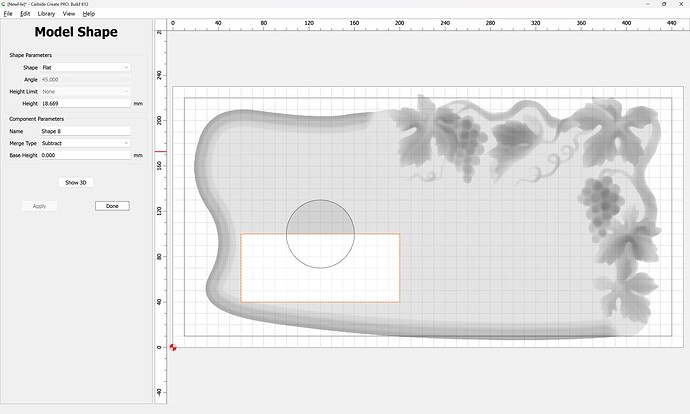

If we then subtract a cross-section:

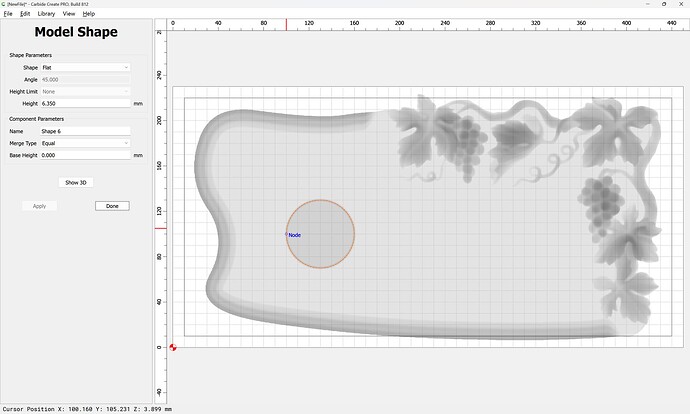

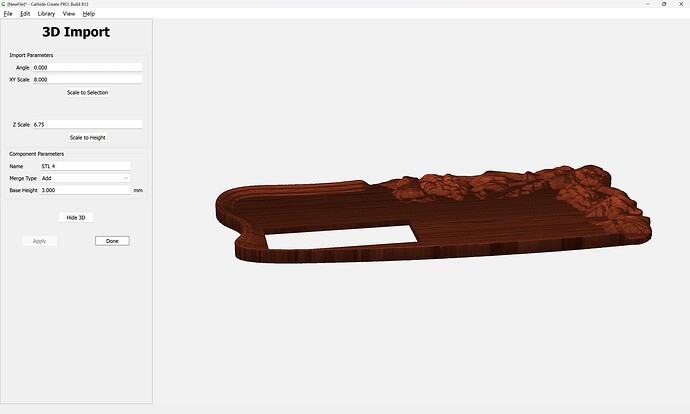

we can see that the thickness is roughly two thirds what is wanted, so we try adjusting the model:

until there is no red showing, and the height of the equal region is the same as that of the thickness of the base.

Done

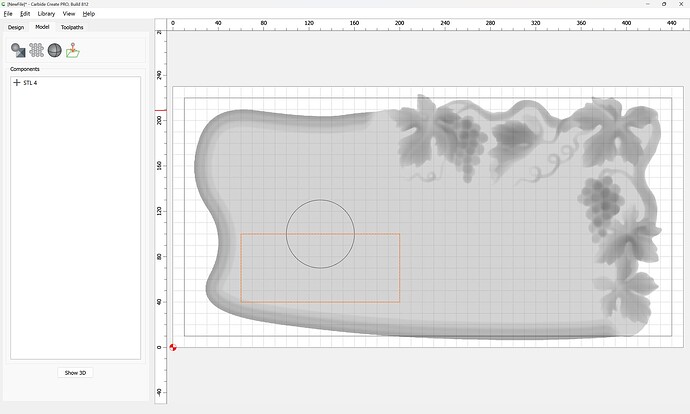

We then delete the shapes used for measurement:

and the 3D model should have the desired 0.25" base thickness and be ready to cut.