Hi all, I’m completely new with the Nomad (and with CNC in general), so I want to ask if this is a problem with my machine or just something normal that I should expect:

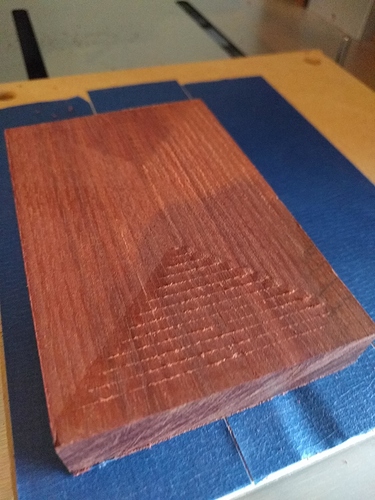

This was produced by a simple “flattening” operation – carving a pocket that’s about 1mm over the entire surface of the piece using carbide3d’s 0.25" bit. I saw this effect on another piece with the smaller 0.125" bit as well.

I was expecting a surface that would not have these pronounced machining marks; for this piece it is very easy to sand them off, but for finer details / pockets it will be trickier and more time consuming. Again, I don’t know if this is a problem with the machine or something I should just expect to deal with with the Nomad.

I figure this happens because the bit is not perfectly perpendicular to the xy plane…so I’m also wondering if there is some sort of “fine adjustment” available I can adjust somewhere in the spindle holding assembly to improve this?

Thoughts?