So i have a customer who’s a jewlery maker that i do alot of work for. She was asking me if i would be able to make impression dies for her, basically a concave 3d image cut into a steel block or something similar. The idea is you take the die and a thin peice of metal to a hydraulic press and press the sheet into the die to form a 3d image in the metal. My question is is how difficult would something like that be to CNC? I haven’t done much work in 3d with my pro 4 but I’ve been wanting to learn.

How about the Advanced VCarve and Inlay ? The gaps would be the material thickness plus something.

Well, you can’t just have one side of the “3d image”. You have to have both sides with the “sheet” pressed between them.

When you do that, you have to leave room between them for the sheet and all the intricacies of details.

Research “tool and die maker”.

They could be hydroformed where the male side of the die is replaced with compressed liquid.

A little more complex than a standard die, but you only have to make one side. Or better put, you only have to make the top die once.

My apologies if my terminology wasn’t correct, im not looking go make an impression die to produce a fully three dimensional shape, just one side for ear rings, pendants etc.

What Tex was describing is in order to press a thin sheet of metal into that shape you need something to push down the top side. Whether it’s another die with clearance for the metal thickness, or a liquid under pressure, something has to push it down into that die.

You can definitely make these on your CNC. On a “jewelry” scale you’re probably talking about some pretty small tools, an ‘micro-machining’ using high speed machining strategies with very small depths & stepovers. Steel might be out of the question for these machines. But aluminum, brass, bronze, kirksite, or even some very hard plastics for short production runs are feasible.

Ok, then now that sounds like a subtractive process rather than a pressing process.

That’s what we do all the time with our CNC machines. You’ll just have to use tiny tools, as @Tod1d states.

Whats to stop you from producing both the positive and the negative using say an STL if you have no angles greater than what your bit allows in both directions.

Edit you don’t want an impression in the backside? Machining is probably your only choice

The process Chris described sounds like “stamping”, which would require a 2-piece (block & punch) die.

Alternate processes would be “forging” in which an ingot (billet) would be pressed into the die using either a formed punch, or even a flat punch.

Molding would require only the female (Bottom / Drag) side of the mold, but also require the part material to be molten & poured into the mold.

So, identifying the part & mold/die material and the process to be used would help answer the question

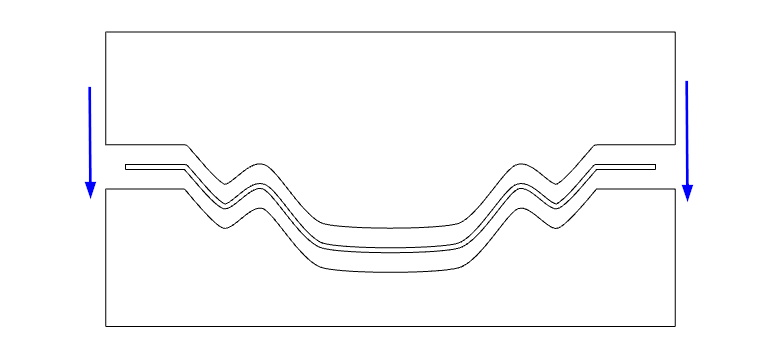

The jewelry maker is probably doing “Impression Forming” using urethane as a backer instead of a second machined die for small pieces. You can get a decent amount of detail with thin copper or silver sheet with that and a hydraulic press.

Here’s a video that is more about the size of the urethane backer than the entire process, but it pretty much covers the whole process in a short time.

Ok, so definitely a subtractive process for the OP and making a steel die with high pressure durability … just like he said in the original post ![]() .

.

There’ll be some work involved in getting those 3D details in steel.

This topic was automatically closed after 30 days. New replies are no longer allowed.