I am new to CNCing and to the Shapeoko community and wondering if anyone could share some tips on how to achieve a better surface finish on aluminum parts. I have seen posts of guys like @Brasch, @Vince.Fab, and @Able getting parts off of their HDM with an incredible finish. I’m running an S5P and Saunders machine works fixture plate with mod vices. I use Fusion 360 for CAD/CAM. Datron single flutes and SpeTool single and 3 flutes have been my go-to so far. Any help is much appreciated!!!

Share some screen shots of your milling tool paths and feeds. The key for a good finish is leaving some extra stock like .005" on the floor and walls with the stock to leave box when roughing and then come back with a finishing pass.

I do my floor finishing pass first staying .005 away from the wall and then come in and do my wall finishing staying .001 above the floor. This gives me the best finish.

I have also reduced my accelerations in order to improve floor finishes.

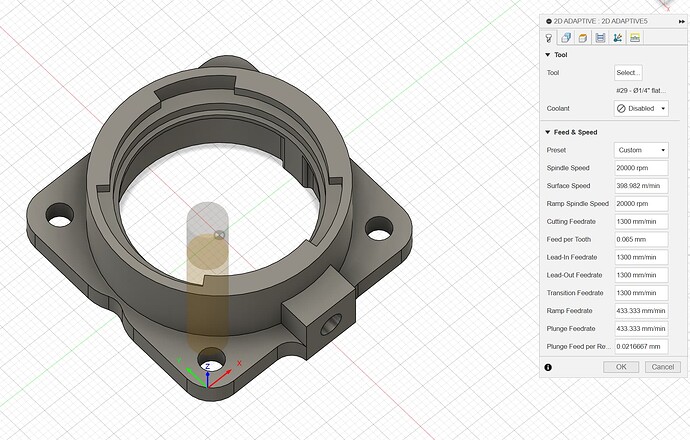

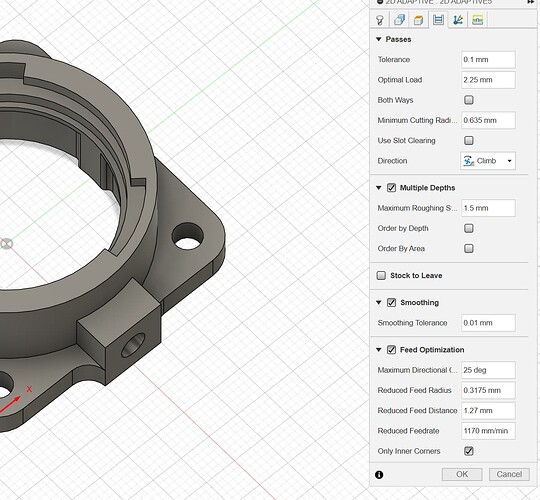

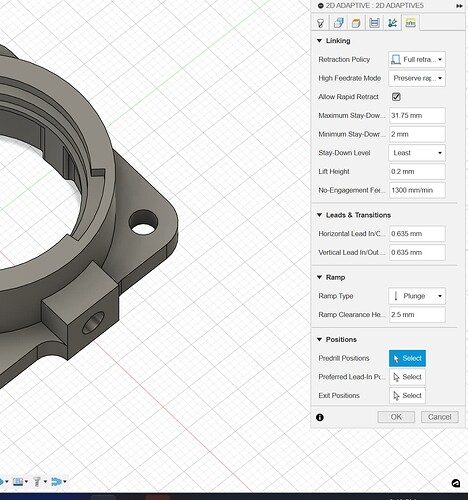

@Able Ok, I see. So do you create another toolpath to come back in with rest machining and smaller stepover/DOC to finish the stock removal? Here are some screenshots of the adaptive.

@nwallace Do you do this in Carbide Motion?

I haven’t used Carbide Motion or GRBL in a long time. I believe there is an MDI available where you can send commands to the machine. You would just edit the GRBL acceleration settings for each axis. I can’t remember what parameters they are off the top of my head. I saw a decent improvement by dropping them by 20%.

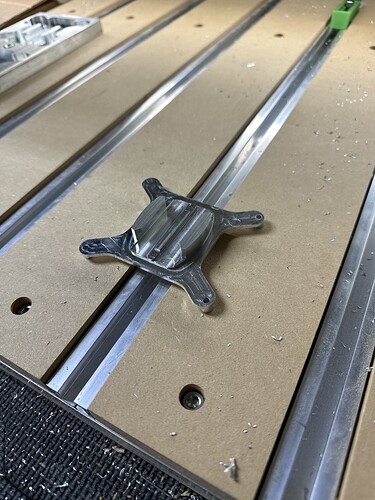

First off, great result for being new to it. ![]()

Adaptive is a good material removal, roughing operation. But not made for a good finish. I usually set a radial and axial stock to leave of 0.020" for adaptive toolpaths and use the single flute. Then come back with a 2 flute and pocket and contour toolpaths to finish it off. I usually do a full depth cut with a 0.005" offset finishing pass at about half the speed of the adaptive and repeat the pass with zero offset to make sure dimensions are accurate and the finish comes out good.

@SLCJedi I will give this a shot. Do you mean that you leave 0.005" radial stock and come back in and clean it up with one last pass? Or do you mean with a offset in the “heights” tab?

There’s an option to do a finishing pass in most toolpaths. I usually set that to 0.005".

Thank y’all for the advise and tips. I really think the finish improved a lot by leaving some stock for finishing passes.

I have a SST lube cube on order for air blast/lube. What kind of mix and ratios are you guys running in your machines? I’ve read a mix of alcohol, water, and CoolLube?

I know from experience that the reservoir that comes with the sst lube cube is not compatible with alcohol. He has had multiple customer’s reservoirs spontaneously shatter after prolonged exposure to isopropyl. I had to swap mine out for one made from a different material. I run straight 90% isopropyl from the bottle with it turned down enough that most of it has evaporated about a minute or so after the cut is finished.

I have been running QualiChem XTREME CUT 251C from Tormach that @Vince.Fab recommended. It doesn’t evaporate cleanly like iso alcohol will, but it has great cooling and lubrication.

@nwallace where did you get the different reservoir from?

@SLCJedi im going to look into this. Do you think it could mix in with alcohol for less cleanup?

I’m assuming you just run a very light mist of coolant?

@Brasch i feel like I read on an old post that you run a mix of some sort?

I use Koolmist 1/8th + half alcohol and half distilled water with a SSI mister. The mix helps a lot. I’ve tried straight alcohol and it didn’t work as well

Maybe. But I’ve also seen the SST canisters crack under pressure with alcohol. I imagine any alcohol increases that risk. There’s also the possibility that the alcohol will counter the oil in the coolant.

Yes, I do a light mist most of the time. I’ve rarely done a heavy mist of I was really pushing in a long job.

I bought a generic one on amazon. They are just filter housings.

Thanks guys! When my lube cube comes in I will see mix up something. Ive got a 2.2kw spindle on order cause the Makita is not doing the trick.

Side note: How are you combating all of the chips on your ball screws? I can’t imagine running the machine with the ball screws covered in oil and aluminum shavings is going to bode well over time.

@Brasch I ordered some Koolmist what is the 1/8 you referenced? I know you said 1/2 alcohol and 1/2 water. Is it denatured alcohol?

@nwallace do you know if denatured alcohol has the same effect on the canister?

The 1/8 is the koolmist, I’ve been running this mixture in the same canister for about three years and haven’t had an issue but I hadn’t heard about them exploding like someone said. So we’re going to check it out this week when we’re in the shop see if we should replace it.