Hi everyone ,

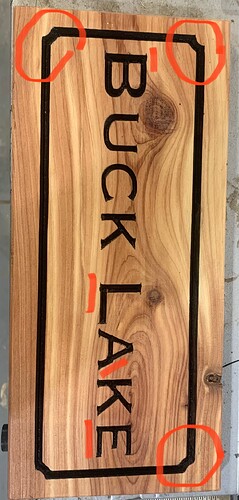

I’ve got a Openbuilds lead 1010 that I’m using with carbide create. I’m experiencing inconsistency’s in all the projects I’ve made. Most of them are v carvings with a 60 or 90 degree bit. This machine is roughly 48”x48” so I realize there could be some lead screw whip but I’m only using the first 12” of the machine. Should my feeds and speeds be slowed down ? This picture is just one example ,some corners are sharp like they should be and some are rounded alone with the miscuts on the lettering Any help is appreciated

Usually this sort of thing comes down to some mechanically difficulty or deflection or no quite right feeds and speeds — does it show in the 3D preview in Carbide Create? If you use a 3rd party 3D G-code previewer does it show in that?

When I preview my piece it shows that it’s perfect. Something happens when it cuts on the machine. I am using cheaper router bits aswell. Could this have anything to do with it

I’d guess the most likely culprit is the stock not being perfectly flat & level (to the motion of the cutter).

V-Carve & Advanced V-Carve are highly dependent on the surface being exactly where it was programmed. If the stock is too low your carves will be narrower than designed. If the stock is too high,

corners will look rounded on the surface.

Any time I’m V-Carving, I will flatten the surface before carving to get the best results.

Aggressive feedrates will try to pull the cutter into the stock away from the programmed path.

Slowing down the feedrate, and/or reducing the depth of cut on the tool will help with this.

It would be cool if V-Carve, when picking out corners extended the motion above the surface a bit to account for imperfect stock.

This topic was automatically closed after 30 days. New replies are no longer allowed.