Not sure how to fix this problem - we are cutting knobs (happens with other round things too…) and where the bit enters the wood it leaves a vertical mark that we have to sand out. The rest of the circle is perfect, but the place where the bit enters always has a mark. Any suggestions?

The plunge can cause some bit deflection, so you get the mark. The usual approach would be to first cut slightly away from where you want to be, then do a finishing pass right up to the line.

Post your file if you can, it’s easier to make suggestions if we can see how things are set up.

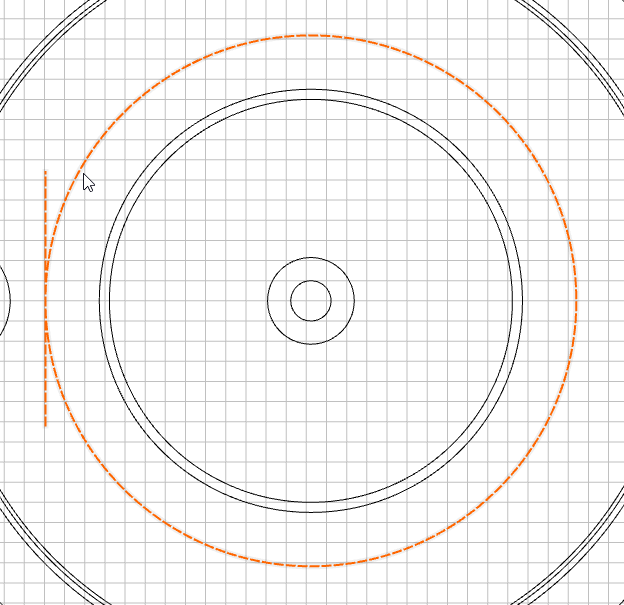

Thank you for your reply. It’s set up for a finishing cut 0.5mm from the rough cut line. (circle #4 & #6 counted from the outside)

Screen Press Knobs - VERTICAL.c2d (348 KB)

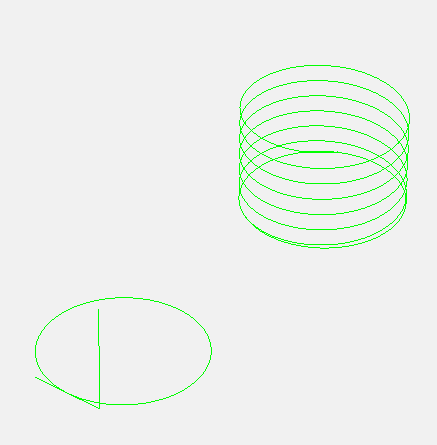

A 35mm deep contour cut? Ouch! Usually you wouldn’t want to cut any deeper than the fluting on the bit. If your tramming isn’t spot on, cutting deeper than the cutting edge even in multiple passes will cause problems.

For the toolpathing, it looks like you are using a really large DOC of the bit to engage areas that are cut down by previous cuts (‘Stem Pockets’ pre-clears a lot of material that the ‘Outside Finish Cut’ would hit). Instead, it’s more usual to set the Start Depth to be the depth of the previous pocket, and use normal bit DOC from there.

For the rough cut, rather than a contour, I would create a pocket slightly wider than the bit (say, about 8mm), and do that instead of the contour. For the finish cut, your DOC has to be less than the length of the cutting edge.

So, I would:

- Widen the ‘Stem Pockets’ pocket a bit, so it’s at least as big as…

- Create a Pocket for the Outside Rough cut, set Start depth to be the same as the depth of Stem Pocket.

- Set the Finish Cut contour to start at the same depth, and cut no more than the depth of the fluting.

Thank you! I will rework the file & try it again!

A couple of ways to eliminate the plunge mark…

Create a 13.175 R circle & cut it & add lead ins. Use a contour no offset

Hole Milling. On the tool set the depth per cut equal or greater than the max depth. Change the plunge feedrate to the same as the cut feedrate. Set ramping to 2-3°

This topic was automatically closed after 30 days. New replies are no longer allowed.