I haven’t used the McFly Cutter before. I plan to use it on some thin plastics (~0.090" thick). I would like to give the plastic a nice finish to remove any scratches and whatnot, but I don’t know how to select the McFly Cutter, since I don’t see it on the Carbine Create v5. Can anyone help?

The specifications are listed on the product page:

Cutting Diameter: 1" (25.4mm)

Cutting Length: 0.39Depth per pass: 0.02"

RPM: 16,000

Feedrate: 60 in/min

How will you be holding your stock? I’d worry about this pulling it up.

I plan to use either double-sided tape or use the painters tape glued together with super glue.

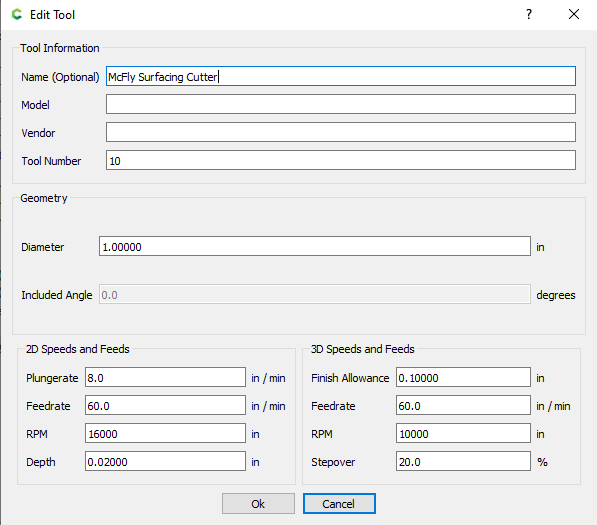

So I guess just make a new tool in the software? I copied the specs from the Shapeoko website, but I Don’t know what to put for the Plungerate in the 2D section. Plus, what’s standard for the 3D speeds and feeds?

Plunge rate is usually half (or 1/4 for harder materals) of the feed rate.

You won’t be using this tool for 3D, so I’d set them to large/small values which would make it obvious that you won’t want to use it for that.

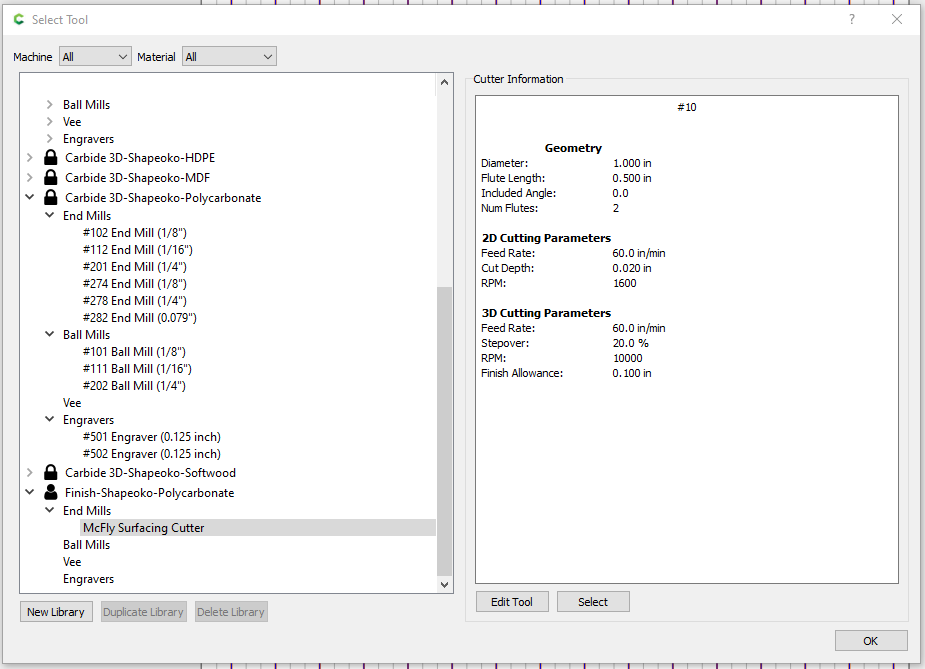

Understood, I just made a new library and a new “end mill” but with the 2D cutting Parameters. Not sure if I can change the number of flutes or whatnot, but I don’t think it matters.

In order to change # of flutes you will need to edit the underlying .csv file — you can access it by About | Carbide Create | Open Data Directory in the tools directory in the Carbide Create directory.

number of flutes is just cosmetic, it’s not used for any calculations or gcode parameters or anything…

Gotcha, I’m not gonna bother with it then. Not sure why the company doesn’t have a surface finishing mill already in their software’s library, but whatever.

Sure the mcfly will be in next version or two. The new products are not updated on sw as fast as the sales sell them.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.