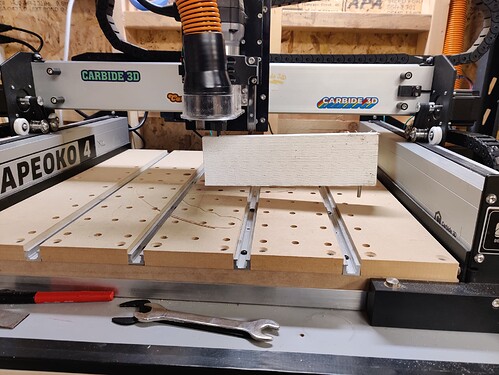

I’m new to owning a Shapeoko 4, and I haven’t used the McFly surfacing bit before. I’m trying to surface a test cheese board type of project in preparation for larger cutting boards. I’ve got it set up in the tool library in Carbide Create (as per Inexperienced with McFly Cutter - #6 by brainy19) and I made a pocket toolpath with a cautious 1mm depth to do an initial surfacing pass.

I zero the bit to the bottom left corner, and I use the XY jog to move the bit over the entire work to make sure I’m not starting too deep. The top of the work is a bit uneven, so I didn’t want to accidentally bite too much wood. I set the zero to be just a paper width above the highest part of the work, it’s fine if it does a 99% air pass, starting slow is fine.

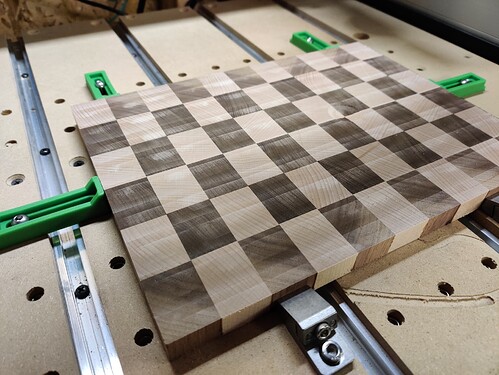

Then I run the job, and this happens:

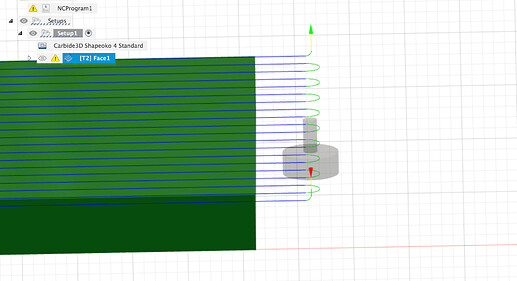

… the bit beelines for the middle and craters into the work, stalling the router. I hit the pause button immediately and the spindle lifts, and I revisit the settings. The plunge is that visible circle in the middle of the work.

After being unable to find anything strange, I zeroed the Z-axis again and found it was 14mm out. How did that happen? No clue.

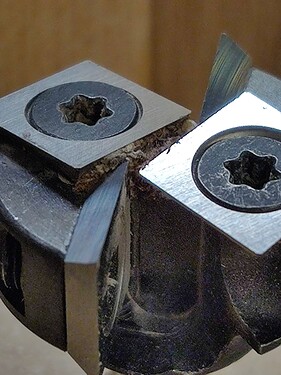

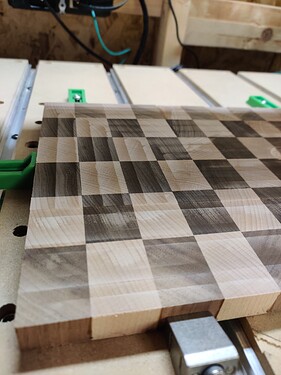

I ran the job again and it worked this time, but the results are a bit surprising. Lots of visible surface defects! In the XY diagonal toward the bottom left you can see the circles as the spindle moves outward, and there are tactile ridges between each pass stepover. There’s also a wide untouched bar in the middle of the piece on the X axis.

I could probably sand this out, it did mostly flatten the work. Is this a good result though? Did I damage the bit blades when it flew into the work? Is there an alignment guide, or should I try rotating the blades and starting with a new side? Maybe the stepover should be smaller?

I also noticed Y-axis stuttering as the bit moved over the work, maybe the feed rate needs to be reduced. So many variables

Here’s the nc: 12x9-1mm.nc (1.6 KB) and c2d: 12x9-1mm.c2d (6.0 KB)

Any thoughts? Thanks in advance for your help

and I have a few photos to share.

and I have a few photos to share.