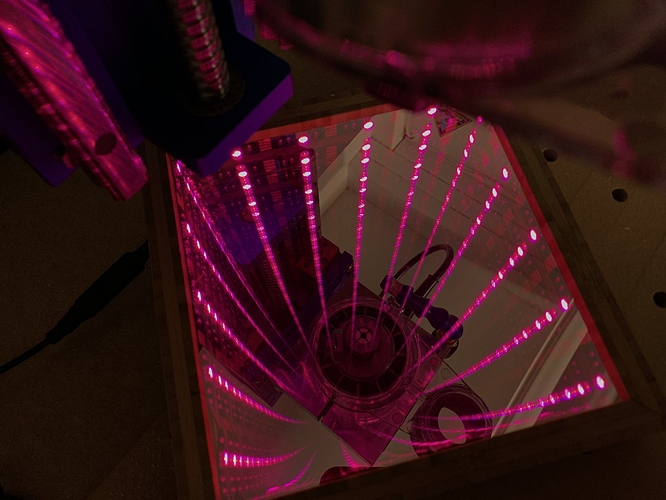

I ended up with some mirrored acrylic and polycarbonate over the course of my material hoarding, so I decided to make a basic infinity mirror. Hit up the video for full details, and let us know if you like the more in-depth format works. It’s more time-consuming to make, but if you get more out of it then it’s worthwhile.

I like the longer / more detailed format…

The first scene where you’re chipping the plastic off the tiny endmill…first time you did it I thought “snap!”. But then by some freak of nature miracle it worked,…until the second time! Been there, done that, made me cringe watching, haha!!! Cool project, thanks for sharing!

Dan

Very cool, I really like the format you used for that video - excellent detail without being boring. Thank you!

Hi Winston,

As always you have produced another amazing video! I was able to learn new techniques from seeing the tool path settings you shared. I would like to make some infinity mirrors soon, and with this guide it will be a breeze!

If you would please consider sharing the files with a fusion public link, It would be very helpful.

Thank you!

https://a360.co/2tsyJz9 <-- Fusion Files

If I’m being perfectly honest, I wouldn’t bother using my files. If you are willing to use more traditional joinery methods for the frame, or construct it differently, it would be a lot more efficient to produce. The frame design I came up with was kind of experimental.

Using box joints or splines would be way easier to get a good fit. Would also be much better if you glued in the mirror at the end, or use tabs to hold the back mirror in, like in a picture frame, so that you could wire up the electronics without being so constrained.

I very much appreciate the tips! One of the parts I most wanted to see is the different tool path settings, and the methods you used to locate the stock you were carving out.

I was struggling with figuring out how to carve models out without creating huge valleys around it with a larger piece of stock. When I saw how you did it, I tried your method on a piece I am working on and it was a huge improvement over what I was trying to do. Studying your tool files will be a huge benefit for my future work.

I downloaded the Fusion files. Thank you!

For fans of infinity mirrors, here’s a recent video of one I found particularly stunning and want to try someday:

For one, I like this style and length/depth of presentation. It’s a project from start to finish, some real world ‘oops’ that mere mortals will also likely experience - and how to avoid/reduce them, and some practical ‘a purist might differ, but in reality…’ honesty which I like.

Great video Winston. Clear and informative. Super new to this world of CNC. As I troll through the amazing content this community has compiled I am fully impressed! You and all the members of the this family that has been created should be proud of all the hard work. Thank each and every one of you for making my journey into the land of CNC a bit less scary.

Another newbie question - would drilling into a block of wood with the end mill with the acrylic blob successfully remove the blob?

I wouldn’t risk it.

I’ve always used a scrap piece of plastic as a tool to remove such — secure the endmill in a vise w/ a set of soft jaws, then carefully pry away at the stuck on plastic always working carefully so as to not damage or ideally touch the cutting edge.