looking at your file; a few comments:

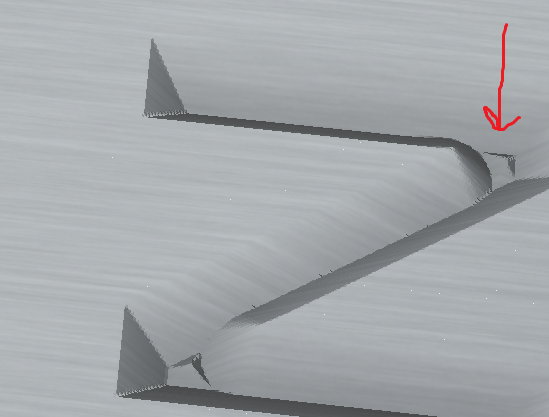

you don’t have a Area Pocket Tool selected for the “female” toolpath; which I think might be at least part of your problem. The font (at least on my machine) is wide enough that some of the V paths would go deeper than the 0.15"… and if you don’t select an area clearing tool, carbide create will cause those bits to not be cleared at all… not even by the V bit. This will result in a “bump up” being there that will get in the way of a good fit for the inlay, see picture of the simulation below:

second comment; I see you have a depth per pass for the V bit of 0.1"… in my experience that is VERY aggressive for V cuts… and might lead to inaccuracies… for most V bits I tend to not go more than 0.04" as depth. (but this depends on the quality and geometry of your V bit as well as on the type of wood)

Might not be the end of the world, but if you want to cut this aggressive, I’d suggest doing a cleanup pass (as I describe in Creating inlays using the new Carbide Create feature)

as others mention it’s usually a good idea to cut the plug in the same direction; in part for accuracies… but also it’s usually better to have the wood grain in the same direction (so expansion/contraction of wood doesn’t fight itself later)