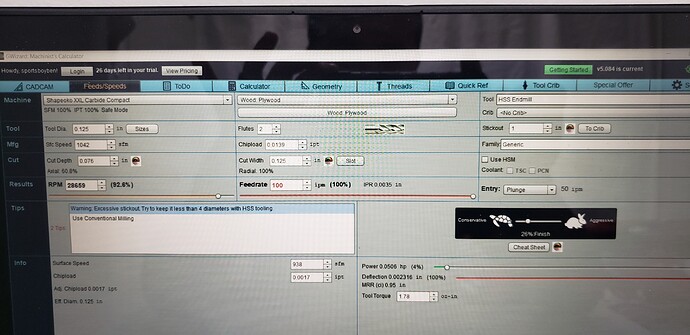

I’m trying to figure out g wizard. I tried putting in my 1/8 bit for a pocket cut. Does this look right?

The feed rate looks a little optimistic.

Perhaps you could try @gmack 's spreadsheet against it for a sanity check?

Right, I thought the numbers were a little high.

GWizard, I believe, is intended for larger, more rigid machines than a Shapeoko.

In plywood, on a regular Shapeoko, I generally start with no more than the bit diameter for depth, 0.001" feed per tooth and 1/2 the bit diameter for stepover, find out what feed rate I need at max RPM for that and listen to the cut.

If you’re slotting (full cut width) then I’d start at 1/2 the cutter diameter for depth, get the feed speeds up and then increase the cut depth until the bad noises start. The problem is that if you get vibration developing on a 1/8" cutter it will probably just snap the cutter before you hear any nasty noises, on a 1/4" at least you get to cover your ears before the cutter fractures…

Right. They break so quick. Even fab lab feeds and speeds tells me 79.5 plunge and 159 feed rate. And I do have my router and machine plugged into the g wizard.

I just posted an updated version of the SFPF calculator with some images showing results of a two flute 1/8" carbide endmill slotting 1/4" deep in hard maple at 200 IPM.

I changed some things on g wizard to many the deflection go down and it now says rpm 18062, feed 36.654, and plunge 18.3. that sounds better?

Not sure about taking the speed down but 36IPM feed rate sounds more likely for a 1/8inch cutter.

The trick is to stay in the 0.001" ish feed per tooth and work up the depth or width of cut until the cutter starts to make bad noises.

As Gmack pointed out, if you can get the cutter to that full depth you have permanent tooth engagement on the helix and thus less vibration, as long as the Shapeoko can get you there.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.