I was wondering if it is re amendment to change the feed rates to speed up cutting to better maximize project times. Has anyone done this on there machines???

We have some information here: Shapeoko CNC Router, Rigid, Accurate, Reliable, and Affordable

The Carbide 3D settings last I checked were pretty conservative, and many of these date back to the SO1/2, and so are even more so — suggest using the test cutting method linked from the above page:

When you do so, please share your numbers and we’ll get them added to that page — eventually, hopefully someone will find time to put everything into some sort of sortable table oriented towards the SO3.

I will do some test cuts and record the info for the cutter type I use and post what I come up with.

If there’s

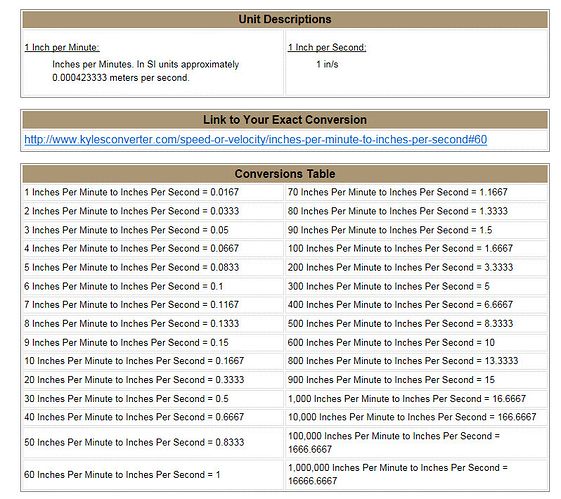

anyone else out there that was wondering how to speed up your feed rate to maximize there machines performance here is a chart that I found that give you set rate per inch@Blackyankeewood

Are you using this chart as a reference?

@ApolloCrowe Are the values in the RPM column the Dewalt Dial Number?

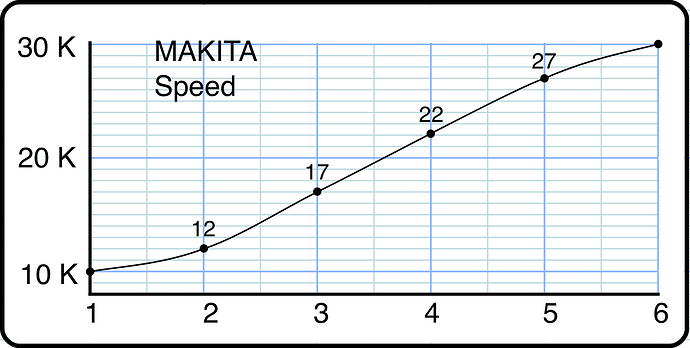

Would you happen to know the dial number values for the Makita router?

Thanks,

Richard

We list measured speeds for both at: http://www.shapeoko.com/wiki/index.php/Spindle_Options#100_to_999_Watts — should be able to calculate the relationship.

@richierich562

The Dewalt 611 Dial to RPM is listed at the bottom of the chart and were established with an rpm meter.

I don’t know the Makita dial to RPM range relationship, but it starts at 10k.

@ApolloCrowe so 2.5 RPM for Bamboo is the dial setting?

@richierich562

Yes the RPM column on the Feeds and Speeds chart refers to the dial position for the Dewalt 611.

Very useful speed chart, thanks Apollo!

It’s worth noting that the chart has since been updated w/ dial positions for the Makita — I believe it needs some tweaking / correcting, and am hoping to see that done before I do the chip load and material removal rate calculations for it as was done for the Nomad version:

https://www.shapeoko.com/wiki/index.php/Nomad_883#Feeds_and_Speeds