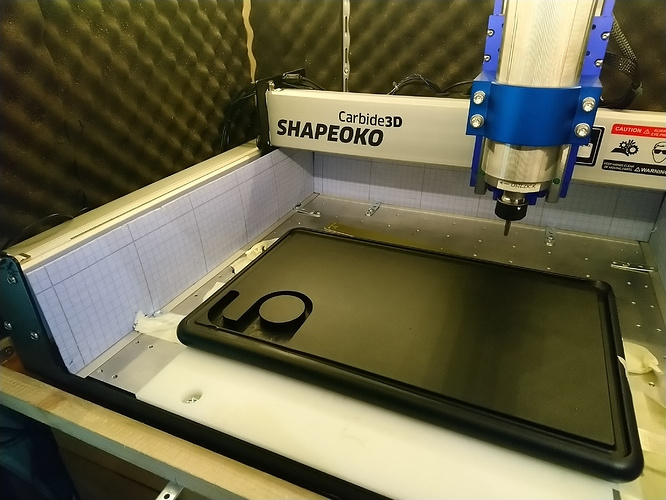

Cutting a big mold job. 20% post-consumer content. 100% stuck to everything.

It’s hard to get the big cutters to cut deep enough without disabling the sweepy.

It’s hard to get the big cutters to cut deep enough without disabling the sweepy.

If you did this and had no disconnect, you deserve a “This machine is properly grounded” sticker

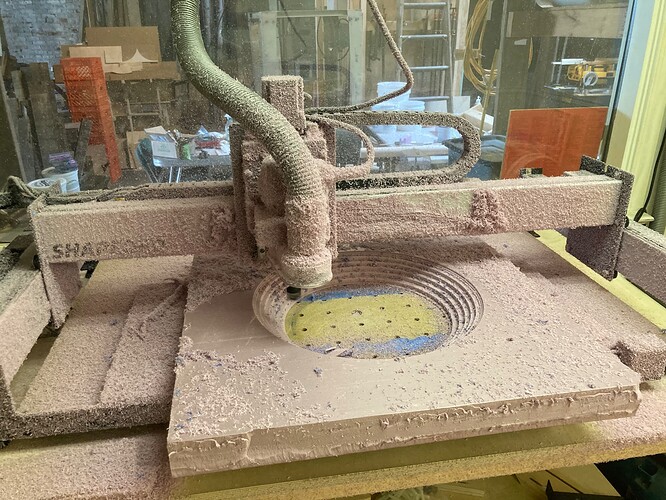

Obligatory re-post of this, from my own “collection”:

Wow! Is that Delrin? Was actually wondering if this clinging was evidence of some latent ground problem, but yeah I guess it’s fine. No freezes or any problems at all. I use the silvery foil HVAC tape to make easy connections all over.

Close. This is the aftermath of milling a black HDPE chopping board

Hahaha! I remember this too. Mine looked very similar but white after milling a bunch of white HDPE. It looks like snow in the white piles that form.

I am not even going to say ha ha ha. I will say, good luck next time in collecting most of it.

@Julien, what type of recipe were you using? Those are some solid chips and as someone that mills a lot of HDPE myself, I am always looking for better recipes to hog out material.

I can’t remember (or find notes) but I usually aim for a 0.005" to 0.01" chipload in butter HDPE, and typically use a sharp 1/4" O-flute, so 100ipm or more @ 20000RPM. This cut was an adaptive clearing, probably around 0.5" DOC (judging from the other pic below and the fact that the cutting board thickness was 3/4"), and probably with 0.0625" optimal load or so

@Julien I’ll have to play around with my numbers some then, I also do not have a HDZ, so that may be a bit ambitious for the Z Plus. Thanks for the numbers though!