Searching through I’ve seen reports of this for a long time but I have figured out how to replicate it.

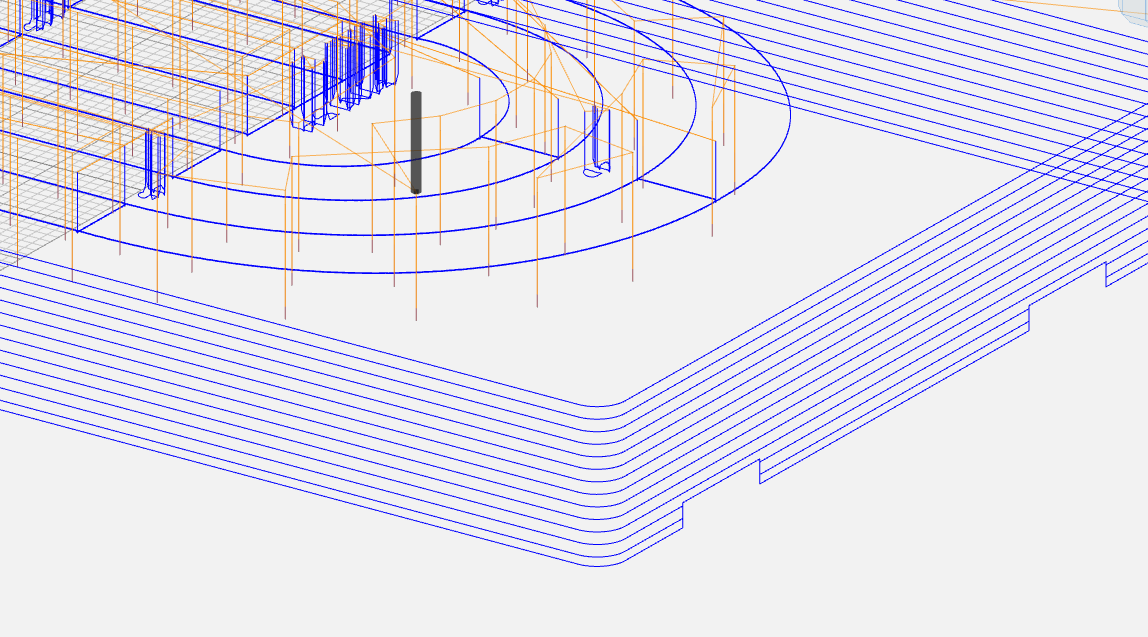

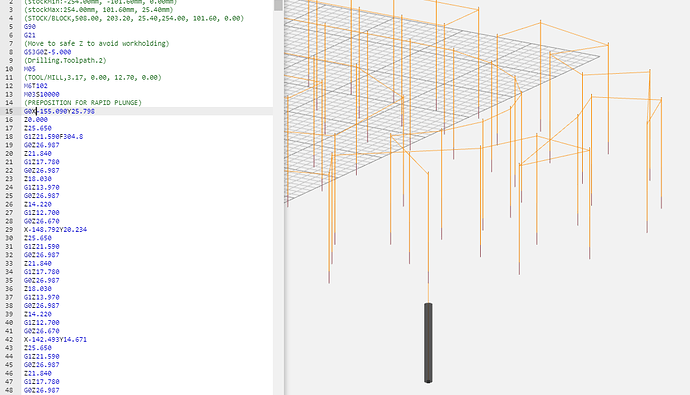

Screen shots will be from ncviewer since carbide create doesn’t show the error with the first hole in the simulation.

Backstory I was making a cribbage board for a friends anniversary. I had a nice piece of wood picked out and decided I’d run a test. Test went well, but then I changed up the order or operations since I wanted to pour some resin before drilling the holes.

Test run drilled no issues with a peck drilling routine.

Time to move onto the actual wood.

Machined all the lines, words, numbers no problem. poured resin, resurfaced it

and started drilling the holes. Simulation in CC looked great. First hole dove fast and hard into the material

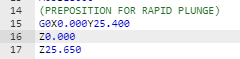

Examination in a 3rd party shows this dive to Z0 that doesnt happen if there is some other machining operation before the drilling operation.

So two items from this,

One, how can I edit the gcode to not do this, I fiddled with it for a while but couldnt figure out how to get the preview of the dive to go away.

Two, can we get the CC devs to look into why this is occuring?

ps. going to try to fill it with a small wood donut from the same board I guess.