I am new to the cnc and am having issues when I set x,y and z. when i set the x,y and z when running a program the machine goes from the set x and y to the front center I press ok then the machine automatically returns to home and plunges into the waste board. any help would be appreciated

Try this.

https://my.carbide3d.com/gswso/06/

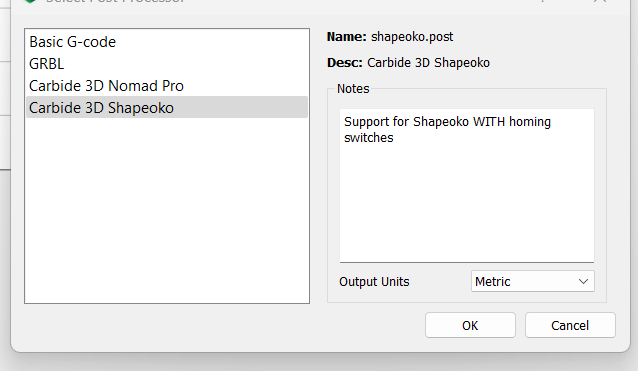

So lets review a few things. When you create a file in CC you must choose the Shapeoko/Nomad post processor. If you choose that then you will get the prompts for the bit changes and the machine will go to the BitSetter.

When you initialize your machine the machine will home and come to the front center and prompt for a bit. Any bit can be inserted or the one already in the machine. The machine should travel over to the BitSetter and plunge twice. This is measuring the offset from the current bit and the last time you physically set a Z Zero. That last time could be the last time you used your machine or after you set the Z zero with the BitZero or manually set Z zero with a piece of paper.

Never change a bit in the router without being prompted by the software or using the Load New Tool. If you manually change the bit without a prompt the synchronization between the last set Z Zero and the new bit is lost.

If you are not being prompted for a bit you likely need to select the Shapeoko post processor. That choice is located in the Edit menu in CC.

The Basic G-code and GRBL will work but will not prompt for tools or the BitSetter will not be used. If you have a 3rd party machine choose Basic G-Code or GRBL but if you have a Shapeoko choose that for the full capability of a Shapeoko/Nomad.

Also review:

If you continue to have difficulties, let us know at support@carbide3d.com

The issue is after the initialization of the machine and settings. When I go to load a project and set the x,y, and z it then again asks for a tool change after I have selected the run operation then the machine goes back to home, instead of cutting the project at the x and y coordinates I just set. I am using the Shapeoko post processor when creating the file but I am failing to understand why it is asking for a tool change and re-homing again after i started a project.

Do you have a BitSetter?

If so, is it enabled and configured properly?

If you don’t, is it enabled? If so, disable it.

What does your simulation look like for the job. If you have empty toolpaths the machine starts the job and then finishes without cutting if the toolpaths are empty.

With a BitSetter enabled during initialization you asked to insert a tool. When starting a job you are asked to insert a tool and both times the bit is measured.

There no way around being prompted for a tool with the BitSetter enabled during initialization and again when starting a job. Even if you run the same job over and over you will be prompted for a bit before the restart of a repeated job. Just the way the software works.

Now even if you toolpaths are not empty if you chose a tool that is too big for the cut you are trying to make the job will not attempt to cut. So look at the simulation and see if there is going to be anything cut.

Post your c2d file so we can see what is going on.

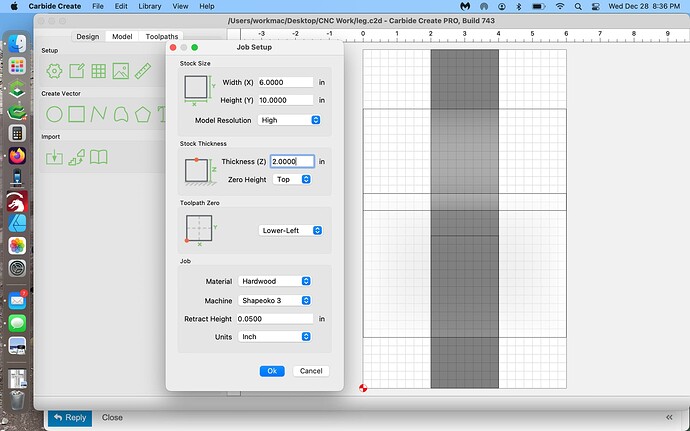

I sounds like your your not setting X, Y, Z in the same place on your stock as where its located in your design file. If you set your job origin at the lower left corner in Carbide Create be sure you set X, Y, Z zero at the lower left corner on your stock after securing it. Also, if your are setting Z on top of your stock be sure thats the setting selected in Carbide Create. The stock thickness setting also has to match what your working with.

This topic was automatically closed after 30 days. New replies are no longer allowed.