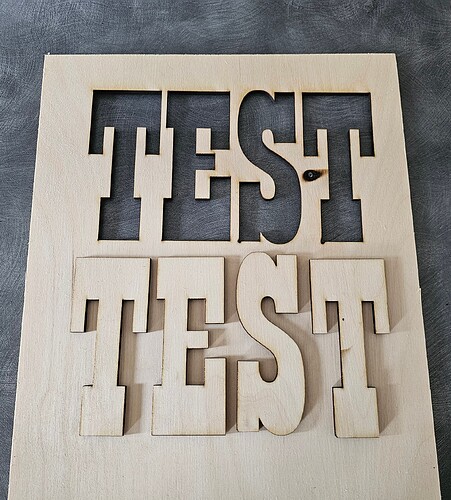

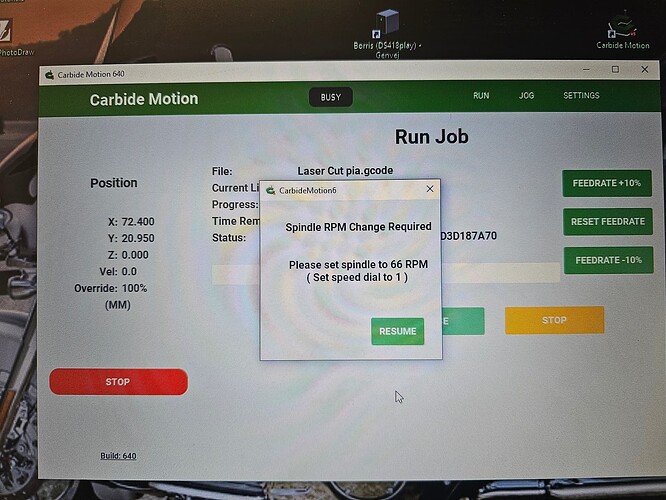

I have instald a 44 W laser on my shapeoko 3 xxl and i am using Vectric laser modul to create the g code. When i transfere the gcode to the carbide motion it starts cutting / burning acording to the power that i set in. But the problem is that it only runs to the first change ig the gcode (i persume) and then i have to press resume to make it continue it tells me to adjust the spindel speed ???

I have tryed to change the Post processor but without luck.

I think most people using a laser use something other than CM when the laser is operational for the gcode such as LightBurn.

As Collen said, most use something other than CM because for some reason it doesn’t play well with a laser. I too use the Vectric laser module and then use Sienci’s GSender as the gcode sender. Works very well.

I think it should work if you configure CM to have a VFD, which should eliminate the popups.

But you would have to reconfigure CM every time you switch if you don’t have a VFD.

Or can you have 2 separate instances of CM coexist and pick the one you want for the operation at hand?

No, because the preferences/settings are saved to a file in a common location, not tied to an instance of the app. Only way that would work is if you used a separate tablet computer for lasering.

Get Lightburn. You have a program that is designed for laser and changes from CNC mode to laser and back with macros. The Lightburn software is relatively cheap and its project creation and handling of images is quite good.

I will second that suggestion. It’s all of $30/yr (I think it’s going up to $50 in a month) with all updates included. It’s a well-written piece of software that has a log of powerful design tools. There are a few little things that I don’t like about it (I know, a surprise, right?) - like the jogging mechanism and the way the screens are packed — I mean really packed - but all in all, it’s a nice tool.

And - as an added benefit - you can go between CC and Lightburn by exporting/importing SVG files…and the companies have modified their products to deal with each other’s default densities…so you can move your designs back and forth with ease. I often bring my CNC designs into Lightburn to take advantage of their tools and the then bring them back to CC to generate my GCODE.

I think both products (the Pro version of CC and Lightburn) are worth it.

- Gary

As someone who has had a JTech on 3 different Shapeokos, has an Ortur standalone diode, and runs a C02 at work…I will also echo to get Lightburn.

Light burn looks iffy on RPi unfortunately.

If you feel comfortable enough, you can edit the gcode text file and remove the offending commands. I have Windows as my OS, and I use the really basic “Word Pad” and edit my files as needed to add or remove commands.

Sometimes, if I am off on the feed speeds by a lot, I will do a find/replace of the speed command through the entire file, since I separate my files by bit size/type. My computer that I generate the gcode is in the house, and I’m too lazy to come back in to generate new gcode, so I just edit the file on my server.

So, if you don’t need the speed command, do a search / replace for that command and replace it with nothing.

As of October 1st, 2024, Lightburn has changed is licensing plans. They now only have two types of license & prices. I believe they went to $99/yr & $199/yr USD.

I don’t remember the exact details, but I think the $99 version is for Arduino based laser controllers & $199 is for everything else.

Check Lightburn’s site for actual details & YouTube for more details.

Looks like it’s $99 for a permanent Gcode based license. So the price jumped but it’s still a permanent license (with some limitations on how long you’re entitled to free updates).

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.