Nice!

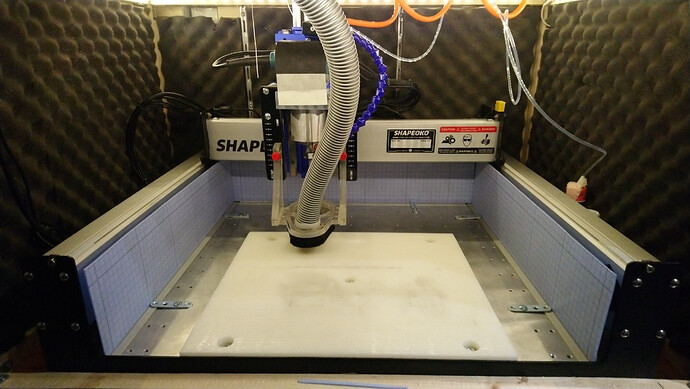

I have been using those for the sides and back of the machine:

which turned out to be quite effective for containing aluminium chips, and that week-end hack ended up being my permanent solution

I installed additional chipguards for the Y rails (but ended up removing them)

Yep, I just plugged my cooler and VFD into the same outlet, using a 2-outlet extender. My reason was not only to turn off the pump when the VFD is off, but mostly to ensure that I could not turn on the VFD and forget to turn on the cooler…which would be a good way to kill my water-cooled spindle.