I am curious about the key hole toolpath. I have a Diablo key hole bit, do I need to add it to my tool list to use the key hole toolpath?

Yes, you will need to create a tool for it which has suitable feeds and speeds.

Thank you. I will contact the manufacture and ask for recommendations on feeds and speeds.

I had a similar bit and wasn’t that smart. I just flipped my piece over and manually jogged down and a 1/2” or so in one direction. It wasn’t a critical piece though so having it officially in the system wasn’t a big deal. Would be good to do for more important pieces.

I just added it to my tool list and used IDCwoodcraft feeds and speeds for their 3/8 keyhole bit. It worked perfect.

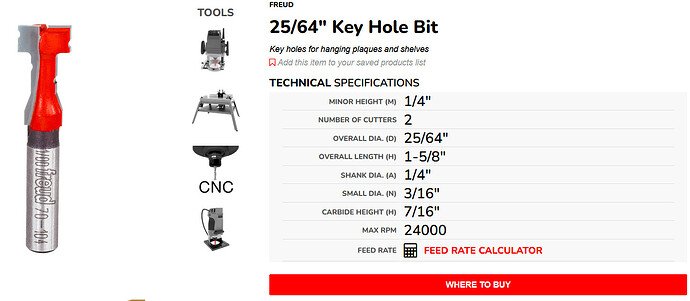

Be very careful using the OEM recommended feeds and speeds. For instance I have a Freud key hole bit and their recommended F&S is fantastically high for a Shapeoko.

Here is my custom tool for the Freud bit.

| number | vendor | model | URL | name | type | diameter | cornerradius | flutelength | shaftdiameter | angle | numflutes | stickout | coating | metric | notes | machine | material | plungerate | feedrate | rpm | depth | cutpower | finishallowance | 3dstepover | 3dfeedrate | 3drpm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 701 | Freud | 70-104 | 701 Keyhole | end | 0.39 | 0 | 0.25 | 0 | 0 | 2 | 0.125 | 0 | 10 | 60 | 16000 | 0.4375 | 1 | 1 | 60 | 16000 |

Here is the Freud 70-104 specifications from the Freud site.

I am not suggesting you use my tool but you can see in my custom tool the places I entered the parameters from the Freud site to make the custom tool database.

Thank you. I apprciate it. I am going to use your settings. Thanks again

Dont use my exact settings because your key hole bit may be a different size. Get the diameters from the OEM or measure them.

To further refine a custom tool:

- Open CC and go to help and about.

- Select Open Data Directory.

- Navigate to Carbide Create and Tools.

- Find your custom tool and double click

- The custom tool database should open in a spreadsheet.

- Add any parameters you want.

- Save As a .csv file and do not allow the spreadsheet to save in its native mode because CC cannot read a spreadsheet file. The file is a text csv file when I save it in LibreOffice.

When you use a keyhole tool path you mark the entry point by drawing a circle the radius of your bit and the bit makes a full plunge. Then it goes forward the amount you specified in the keyhole tool path.

You create a circle the diameter of your bit. Then in the tool path you tell it how far to plow forward. Attached is a sample c2d file from v7 756.

keyhole_example.c2d (136 KB)

Make sure your bit is big enough for the screws you want to use. Also make sure you make the smaller diameter part far enough to the head of the screw is not going to be on the edge of the circle.

Since this is a full depth cut and then the bit moves forward to plow out the countersink hole for the screw head take it easy because a Shapeoko can only go so fast at a full depth plunge.

One additional thing I do is usually do a vcarve and make the distance between 2 key holes plain and an even number.

Thank you. I have the exact bit as you.

If you have a BitSetter…

In hardwood, I rough my keyslot with a 1/4" endmill first, then use the keyslot cutter. Makes the T-slot a bit more pleasant - less likely to burn, longer life on the more expensive tool. Overkill perhaps for a one off, but for me

- 1/4" endmill does a pass that’s about 0.5mm deep, and then pauses

- I can do a sanity check that I put my keyslot in the right spot

- I hit resume, 1/4" does a roughing pass

- Toolchange and finish with the actual T-slot

This topic was automatically closed after 30 days. New replies are no longer allowed.