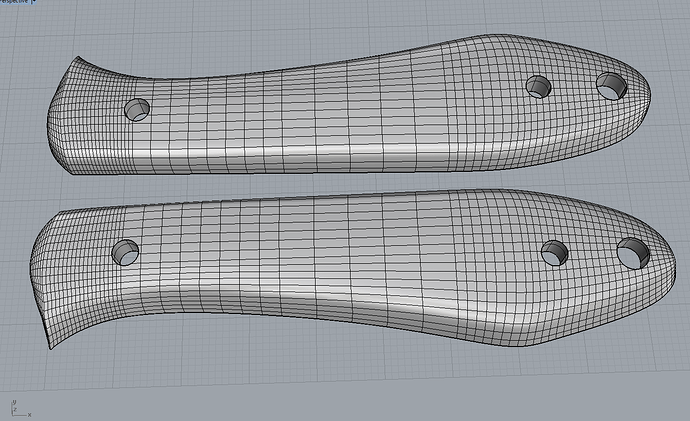

Making Custom Knife handles with an Inlay-

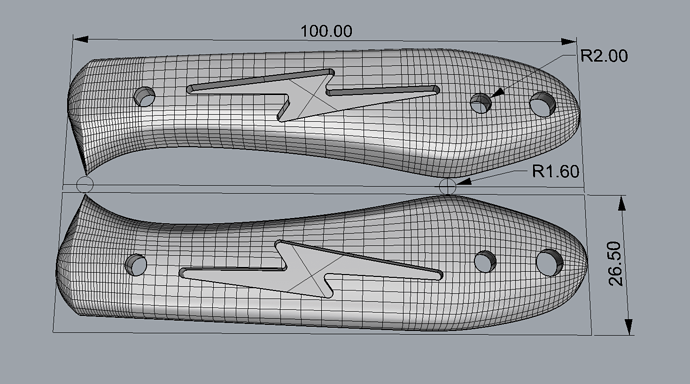

Making Custom Hardwood handles with a metal inlay has its challenges, and by nature any “Custom Inlay” will have its own unique challenges depending on the overall form and specific Inlay design.

Here are some Tips that I found during the process that will help when you regardless of your design.

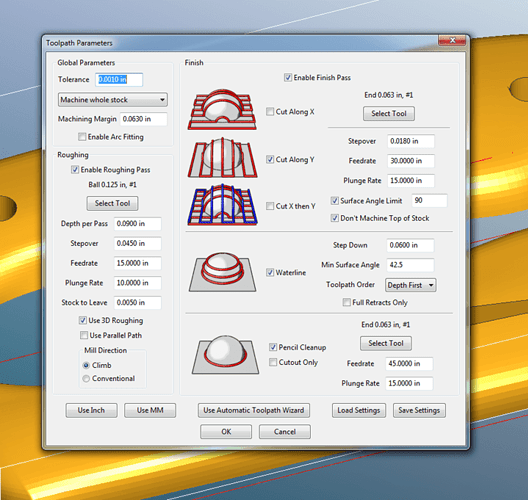

A-Test your file in Renshape or other modeling stock first to perfect your profile, these hardwoods can be expensive and hard to find.

B-Wood Grain orientation is key-

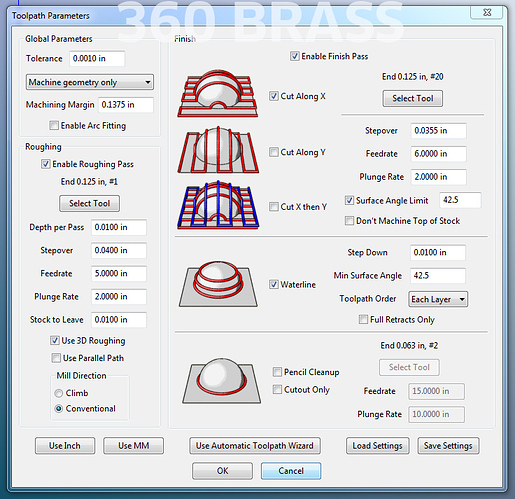

If you find tear out occurring in the wood, change your grain orientation or your parallel finish direction in meshcam. I found cutting down into the endgrain worked best.

C-Separate your Final pencil / cutout pass as a last and separate job, because I used double sided tape the parts can rip free if you cut through the stock too early.

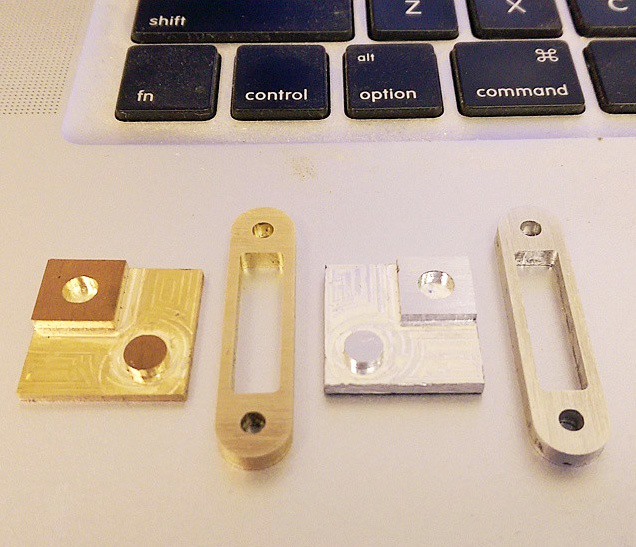

D-The gap between my wood handle and the metal inlay is .1 mm and is a very tight fit.

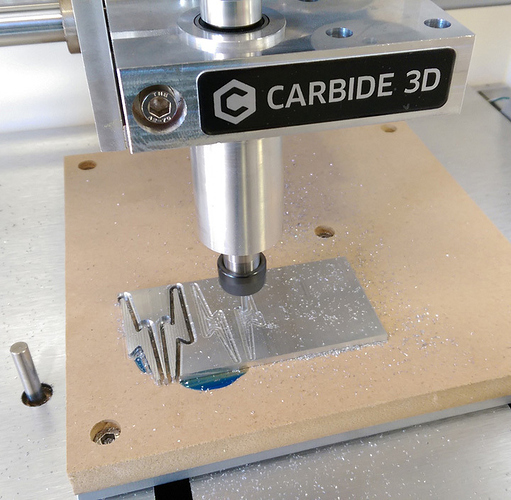

<img src="/uploads/default/original/1X/65d87d27101dda206a8c4dbf369e1f8cb1f167ae.jpg" width=“416”

Purchased Supplies:

200-400-600-800 sand paper

cheap polishing kit from amazon

super thin super glue

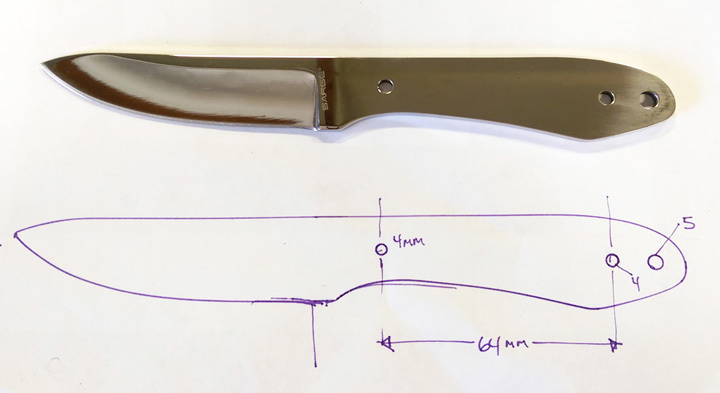

knife blank of your choice

Outline Your Blank

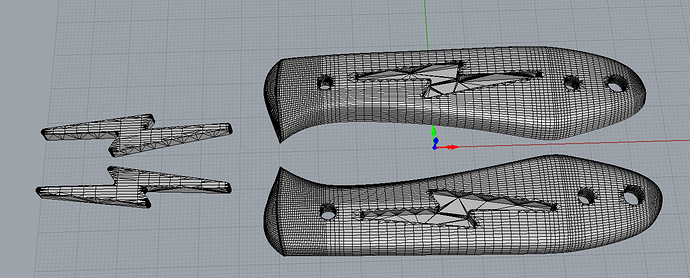

I used Rhino for this project, but most programs have a “Background image” option. I knew the holes in the blade to be 4mm so I could scale the sketch to those features.

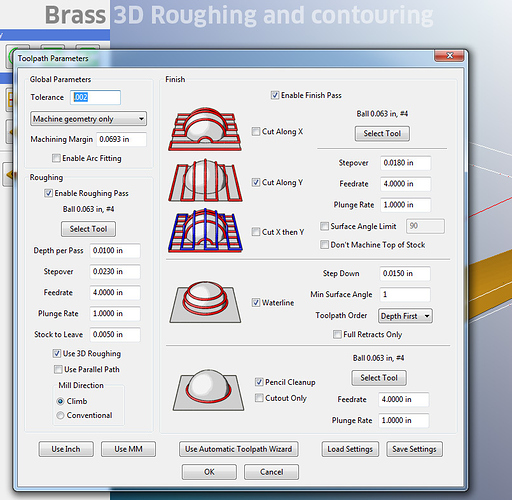

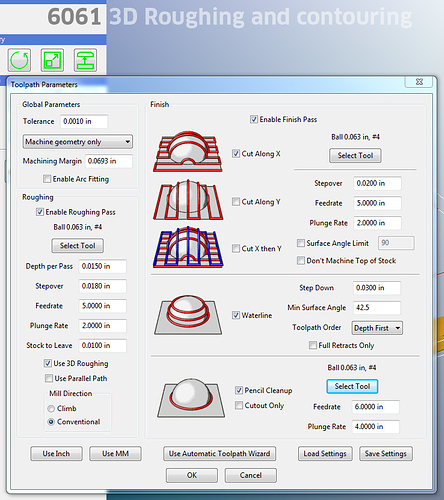

6061 aluminum 1/8 thick

Mahagony endgrain matched blanks.

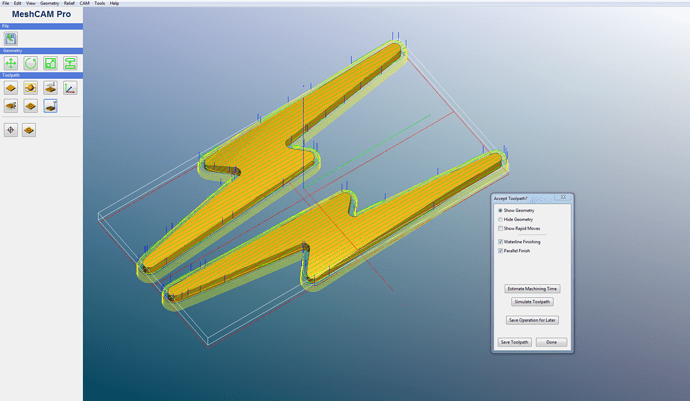

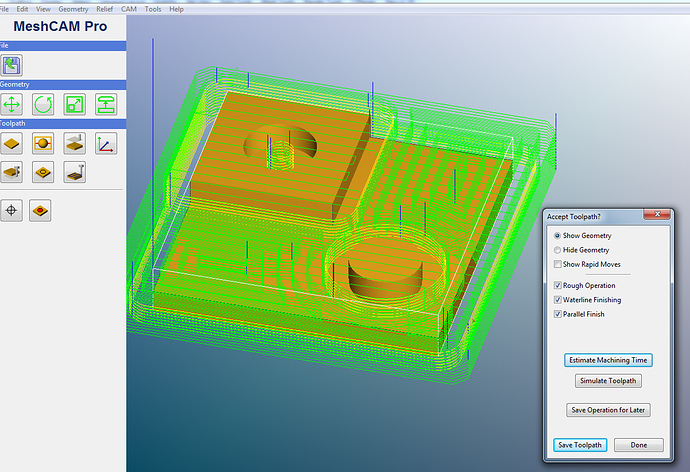

Usually it would not be recommended to parallel finish a 3d contoured part with a square endmill, but since my inlay pocket needed it, and it worked…

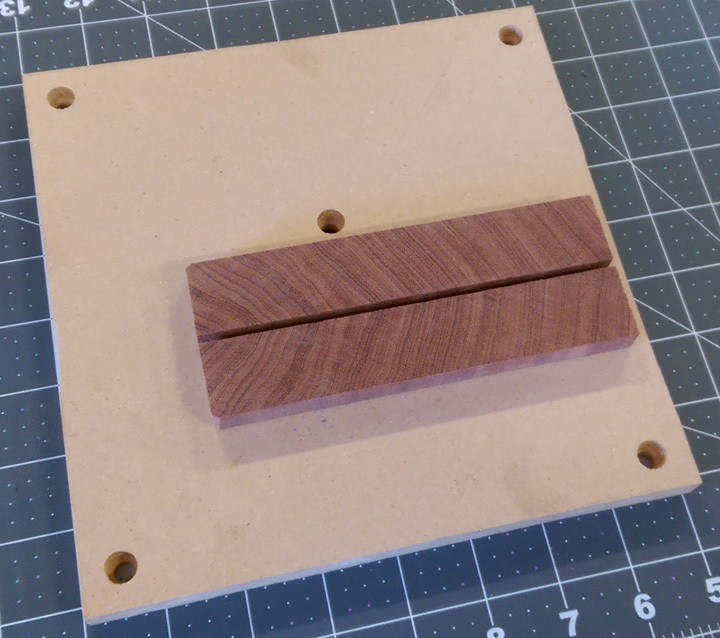

I used a 1/8th thick piece of stock to separate the wood blanks as well as keep them parallel to each other. clamp the stock to the wasteboard and give the tape a chance to grip by wiping your surfaces clean of dust or oil.

This is a tricky place to be, these endgrains are short and want to break, so little by little work the handles free.

This blue fixturing wax is available in the Carbide 3D store:

A little pressure and the inlays went into the recess.

Take the usual precautions to make sure you dont glue your self and your work to your work surface and paint on the super glue. your not done until the entire surface has a thin coat. allow to dry - longer the better, I left them over night to cure.

After much sanding I polished with the kit from amazon, and I was very impressed with the results.

Now lets see how i can share these stl files…