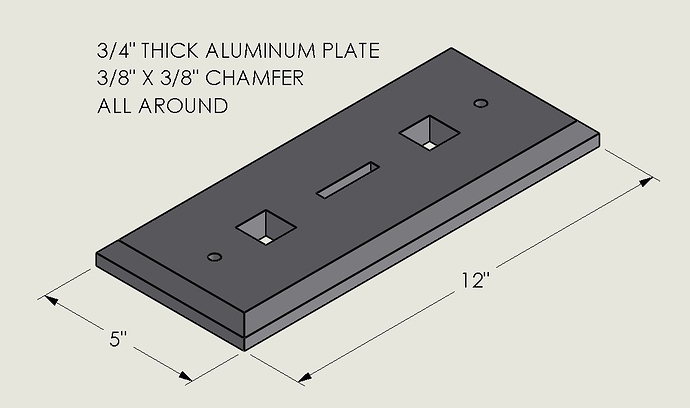

See below - I have to cut a 3/8" x 3/8" chamfer around an aluminum plate. I’m looking for suggestions on how to go about this.

One idea is to use a flat end mill & ‘stair step’ down to take most of the material away, then clean it up on a finish path with a 90 degree v-bit. Ideally that would be with a large enough bit to clean up the chamfer in one pass, but that would require a 3/4" bit diameter?

Or, I might also be able to rig something up at the front of the machine to hang the part over the front & orient it at 45 degrees so I can cut each side with a flat end mill. I flipped my gantry plates so I have less travel at the front than stock, but I think it would still be enough.

I’m using an XXL + HDZ if that matters. Any ideas or suggestions would be appreciated. Thank you!