I have a Shapeoko 3 XL with the 2.4e circuit board. I’m wanting to upgrade my laser to a 10 or 20 watt unit, but am not sure which ones are compatible. Some are 24V, some are 12V, some are 3 wire, some 2 wire. I’m looking at units from Ortur, Atomstack, SculpFun, etc. Will any of these work with my machine? I’m thinking that I need a 12V unit with the 2 wire interface to plug into the GND and PWM ports on the board, but I’m not sure. Any suggestions or advice is appreciated.

Hi @Gawain,

The laser module should have its own power supply, whatever the voltage is. As long as you don’t use the Shapeoko controller to provide power to the laser (and you shouldn’t) the laser main voltage does not matter.

The laser intensity control interface must be a 0-5V analog input (that will be connected to PWM and GND on the shapeoko controller)

So yes, 2 wires, but do check the specs on that 2 wire input, some are 0-10V for example. Some folks use voltage level shifters when this is not the case. In all cases, note that adding a laser module is not a supported mod, so be careful with your controller.

There are threads on the forum to help you figure out how to connect things. With a medium-high power laser module, you will also likely want to plan for fume extraction, it’s a major problem to address when cutting through material with a laser. If you only need to engrave objects, a couple of Watts is enough and will produce vastly less fumes

Julien. Thanks for the reply. That is helpful. I’ve had an Endurance laser attached to it for a few years and it’s worked fine. It is supposedly a 10W laser, but I’m sure that’s far more than the actual optical wattage, since it has a hard time even cutting through cardboard. It looks like the newer ones on the market have the electronics all build into the laser module itself and have the power supply going directly to it. I’m hoping that should work fine with the Shapeoko based on what you’ve said. Yes, I’m definitely going to be working on some kind of enclosure with smoke extraction as well.

I’m a bit confused with some of the products out there as far as what the PWM voltage is. Some of them don’t even list the specifications and others are kind of ambiguous as to what they’re referring to. Has anyone put one of these more powerful laser modules on their Shapeoko 3 XL?

There are folks here who went for the 7W version of the JTech module, which is equivalent to the advertised “20W” on no brand chinese modules (they tend to advertise input power, not actual laser power). Anyway the laser power is independent of its intensity control input type. It’s not a great sign when the vendor does not provide tech details on the control input, or when they don’t answer when you ask. 99% of them are 0-10v or 0-5v though

Maybe this explains why my current Endurance 10W laser has never had that power that the company claims it should. My Shapeoko can only deliver the 5v at 100%, but it is rated for “TTL 3.5-12V”. Anyway, I’m trying to find a higher power one that fits in the 0-5V category and I’m not having much luck. Does anyone have a recommendation?

There are a couple of different connections you need to provide the first is the DC power (9-16V 5A) for the laser and control module, the second is the laser “power” signal that tell the laser module what power to output. This is the signal that you get from the Shapeoko control board. It is a TTL PWM signal which matches the description from Endurance

"TTL wire / wires are also added to the laser driver. With TTL (3.5 - 12V range) you may change laser power (duty ratio). "

Have you set the min/max/mode values for the PWM control?

$30=1000. Max spindle speed, RPM

$31=0. Min spindle speed, RPM

$32=0/1 Laser mode, boolean

Like @LWSIV said when browsing for laser modules don’t confuse the primary power of the laser and the control signal voltage.

Sorry I can’t recommend any particular high power model, my only comment would be that high power lasers tend to come in standalone laser machines, not laser modules for CNCs. If your main goal is cutting through material, chances are you would (surprisingly) have a better bang for buck by buying a standalone machine (it would also have the advantage to take care of safety and air flow, which become increasingly important as the laser power increases)

JTech does have a 14W (as in, actually 14W optical power output) laser module for Shapeoko3. It will cost you though…not cheap.

I think I’ve been coming to that conclusion- I should just find a standalone unit. I was initially thinking just putting on a newer module would be the simplest and cheapest, but I’m beginning to doubt that.

Thanks for all the input!

One other challenge for me is that I live in Papua New Guinea where it’s quite difficult and expensive to ship stuff. I’m thinking of just getting a laser module and replacing my CNC controller board with a new one that will support 12V PWM. I see a lot of options out there for control boards. I use a Mac with Lightburn, Fusion 360, and Carbide 3d apps. Some of the controllers don’t say they are Mac compatible, but I would think if they are GRBL compatible, then the Mac should do fine with the apps I’m using. Am I correct? And does anyone think this is a good idea and have a recommendation on controller boards? One I’m looking at is here: https://www.amazon.com/Engraving-Machine-Control-Engraver-Controller/dp/B07B3RFNJ7/ref=sr_1_8?crid=2ZL7JGVEJYRCL&keywords=Mac+compatible+cnc+controller&qid=1662642597&refinements=p_72%3A1248909011&rnid=1248907011&s=hi&sprefix=mac+compatible+cnc+controlle%2Ctools%2C425&sr=1-8

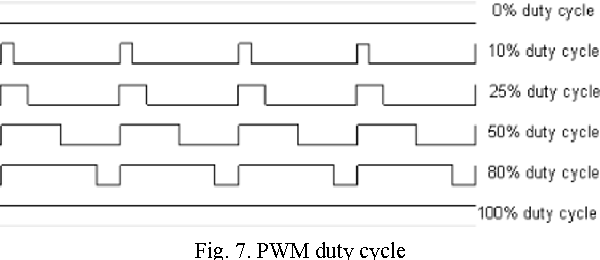

The voltage level of the PWM does not translate to Laser power. It is the duty cycle , percentage of on time, that determines the laser output. The duty cycle is interpreted the same by the laser anywhere in the PWM signal voltage range.

The Endurance interface box should have a toggle switch that allows you to force 100% laser power. I would test that to see if your control (parameter settings) is the issue or if the laser is just not as powerful as you need/want.

If you change controllers you will lose the ability to control the system with Carbide motion as it will only run C3D control boards.

Honestly I think it would take much much less effort to just get an I/O voltage adapter to feed the shapeoko controller’s 5V PWM into a 12V analog input at the laser if you can’t find one that uses a 5V control input

There are cheap adapter modules all over Amazon, here’s an example

But first do triple check what voltage you are referring to. As @LWSIV said the PWM style signal is not used to supply power, just a variable command to the laser. The laser main power (going into the diode) should be from a standalone power supply (and it is often 12V or 24V)

Changing the controller is a messy business, unless you really know your way around GRBL, AND you have checked that the stepper motor drivers will be adequate.

If you can procure those generic GRBL boards, I’m sure you should be able to procure a voltage level converter too. By the way it’s pretty cool that we have a forum member from Papua New Guinea!

Oh and I forgot to address the Mac vs Windows question: there are no good reason why a GRBL controller could not be driven by a Mac. A GRBL controller is interfaced by a UART serial link, and Macs handle those just as well as Windows PCs

@Julien, the option you’re suggesting sounds a lot simpler and cheaper than changing the whole board. I guess I don’t fully understand the PWM voltage situation. While I know it has nothing to do with actual laser power, my understanding (maybe faulty) is that the higher the PWM voltage goes, the higher the duty cycle, thus the better cutting. So my Shapeoko control board is 0-5V and the Endurance laser that I have is 3.5-12V. The max PWM signal it will do is 5V, so the highest duty cycle is less than 50%. Is that correct?

If I get the I/O voltage adapter, then that just increases the PWM output voltage to the levels that I need to control the duty cycle of a laser with 12 or 24 V PWM?

Thanks again for all your help! I know just enough to be dangerous!

Reading a bit more about PWM, it seems that the voltage ratings (0-5, or 0-10v) are telling you the AVERAGE Voltage reading depending on the duty cycle percentage. I’m understanding it a bit more, I think.

Yes, a PWM signal is actually a series of pulses at a constant voltage (5V for the Shapeoko) but toggled at a varying rate such that the average voltage varies from 0 to 5V.

I found that part of the Endurance laser instructions :

It seems like you have version 1.0 of the control box? From those statements, it would seem like the box accepts any pulse voltage from 3.5V to 12V (so the Shapeoko’s 5V is fine), and then it picks up the duty cycle to modulate the laser intensity.

The endurance 2.0 seems to have replaced that with a 0-10V input (typical of what I mentioned earlier), and if you had that one that’s when you would need a voltage shifter, because THEN the box does not pick up the duty cycle at any voltage, but the average voltage, and the Shapeoko will max out at 5V and you would only ever get 50% of the max diode power. Hopefully I did not confuse things, it all depends on the nature of the control signal and that’s something only the laser supplier can confirm

So basically what @LWSIV already said, with that laser you have you should make sure your GRBL setting are correct and check that you do get an average voltage between 0 and 5V depending on the RPM you command during the job.

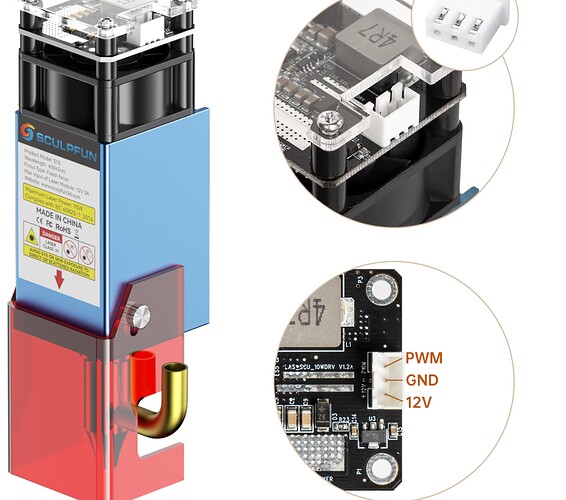

So I went ahead and ordered a Sculpfun S10 laser module to add to my Shapeoko 3 XL to replace the Endurance laser. There is only one plug on the module and it has 3 pins: PWM, GND, and 12V. So my plan is that I will connect the 12v, 5A power supply that I bought to the 12v and GND pins. Then I will take the PWM and GND inputs from the control board to the PWM and GND pins on the laser module, (both power supply and control board inputs sharing the same GND). Does this sound right?

Here is a screenshot of the module connection.

This topic was automatically closed after 30 days. New replies are no longer allowed.