This topic was automatically closed after 30 days. New replies are no longer allowed.

Well it only took 5 months before I got to task #47 on my todo list, which was to integrate that laser zeroing thingy.

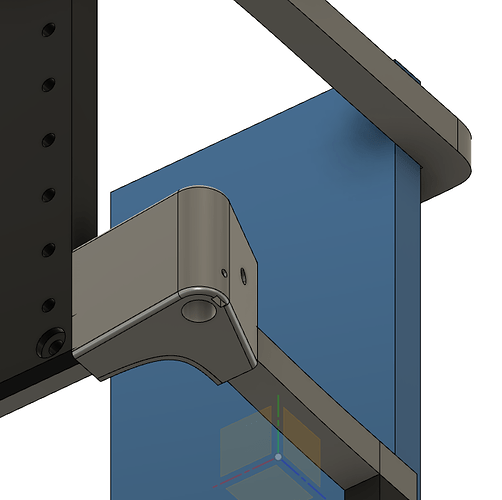

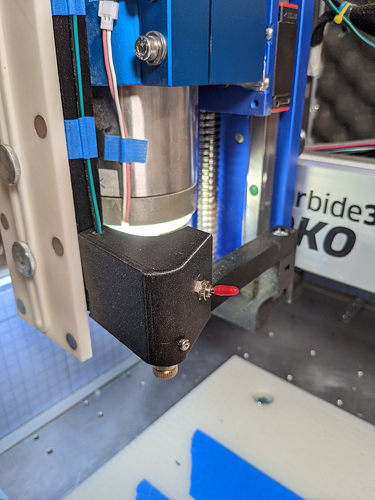

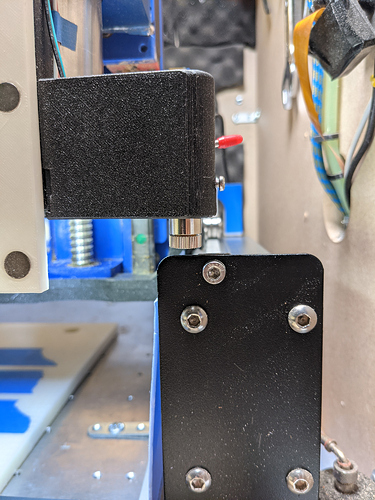

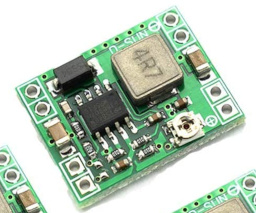

I did not feel like re-printing major parts of my HDZ frame, so I went for minimal effort and designed a snap-on box that would attach to the existing arm, and hold the laser, a switch, and a small 24V to 5V converter (just because I already had the 24V line coming near that location for my spindle ring light)

(no, I’m not even ashamed of using painter’s tape for routing those wires)

The workflow will be:

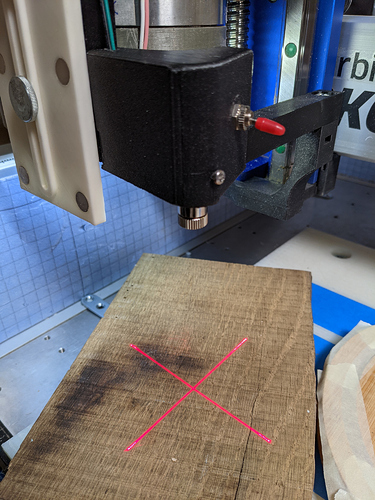

- turn on the laser, jog to desired X/Y zeroing point

- click on a macro to add the predefined X/Y offset of the laser center versus the collet center to the current coordinates, and set zeroes.

The laser clears the right Y rail and Y plate by 2mm, and that is totally not pure luck, of course I had thought of that before designing and assembling everything

this is cool… but like even thinking about it dangerous (I see purchases coming)

The next thing I would want is adding a fixed webcam to my setup, and then a piece of software on the PC that uses basic machine learning/image processing that will recognize the stock based on that, and then controls the laser to the right point and auto finds the edges.

but like I said, dangerous rabbit hole

Yeah, that kind of sensor technology/image processing is one of the big areas of potential development for inexpensive CNC machines — certainly the Glowforge folks did well with it in marketing their machine concept on Kickstarter (haven’t followed the actual implementation).

OLD thread, but worth reviving for this find:

I will have my S4 running again in a few months, at that time I plan to buy one of these and make a mount behind the spindle. This should allow us to get a laser crosshair right on spindle center, no matter the height of the workpiece. No offset jog macro would be needed. The only downside I see is that the crosshair lines would make an “x” and not a “+” ,so the lines couldn’t be used as reference for XY jogging. But I prefer this over the macro.

I had that Wixey laser sight on my old Delta drill press. It was NEVER accurate enough. I know that it’s sends out planes of light and that the planes should intersect anywhere along the travel of the quill … but it never did for me.

I’m, therefore, not a fan.

This topic was automatically closed after 3 days. New replies are no longer allowed.