ok so i have a few observations  F360 can behave a bit wierd some times depending on how you set your stock up, so try this

F360 can behave a bit wierd some times depending on how you set your stock up, so try this

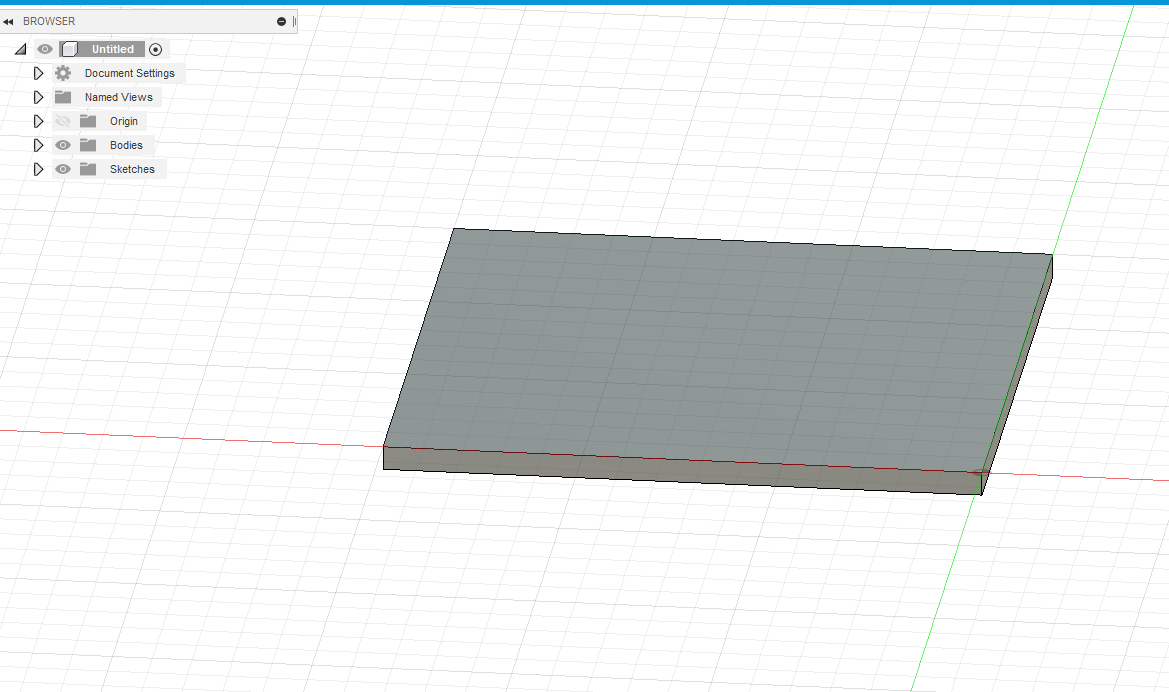

first your stock is really small as in 15mm x 15mm .6mm thick? is this a pcb or something. is this meant to be like this ?

Second

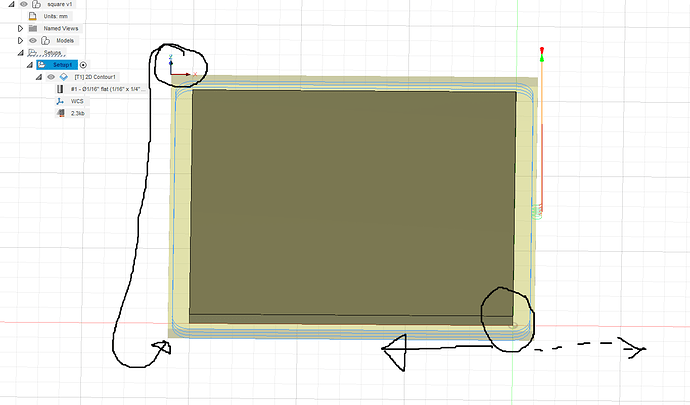

In your file your origin and drawing are odd (to me at least) and i know when i deviate from this F360 at times does not like it. i notice that your file you have aligned to the top left instead of object origin, and then i notice your drawing direction is reversed by this i mean (brace for paint awsomeness)

i normally have my drawings goign in the direction on the dotted arrow

i also notice when i edit your file that it seems like the extrude is behaving badly making it minus - yet f360 is clearly saying it is a plus so that is odd

so what i suggest is this to try and if it still behaves the same come back to us please

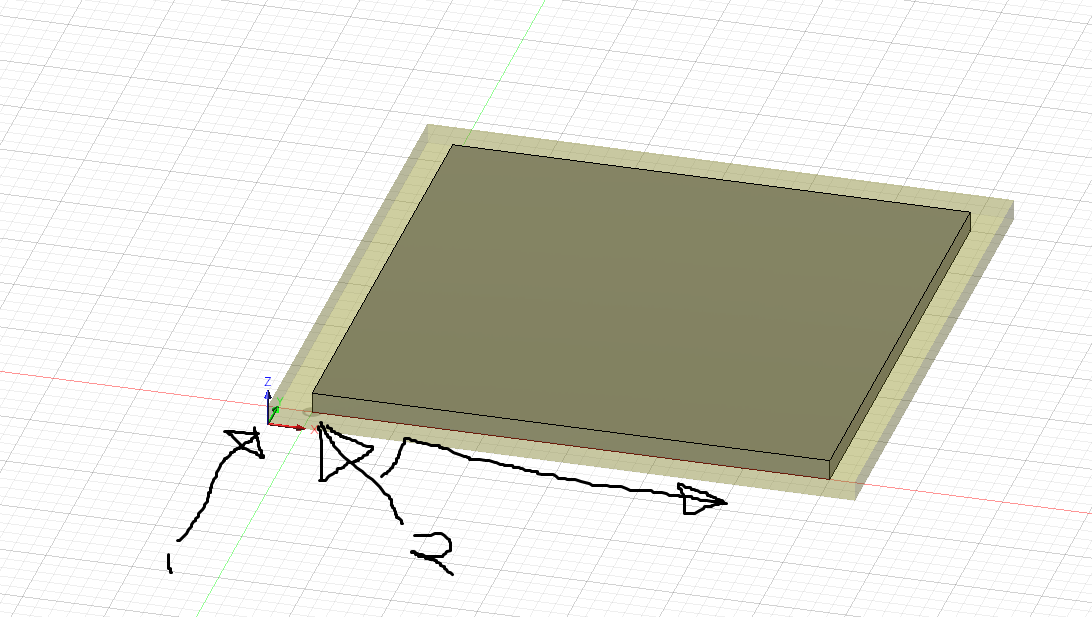

create a new file and redraw the shape so that it runs from the origin to the right (arrow number 2) them make your 0.0 bottom left as per arrow 1.

Instead of it being on the top of the stock if you do it to the bottom you can then zero your machine xy normally but for the Z if you do it to the surface of your spoilbord (bottom of model as per screenshot) it will always go through your stock without the need for that negative offset (make sure you do not put ofset in or it will cut your spoilboard)

Important note your stock hight must be correct or you will either AIR CUT or CRASH, for more info on how to do this see this post spoil board

let me know if that helps, i know other people may say popycock! but F360 is tempramental - or at least it is for me  if i stick to the above works a treat!

if i stick to the above works a treat!

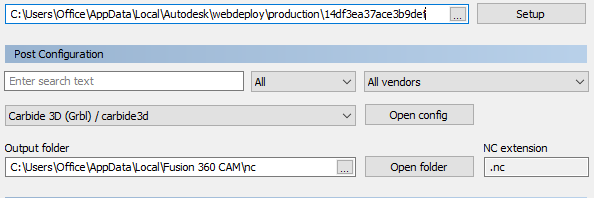

EDIT ** forgot to ask what post processor are you using to output the gcode? should be

Jon