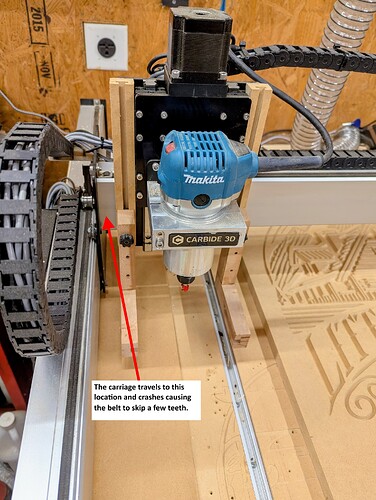

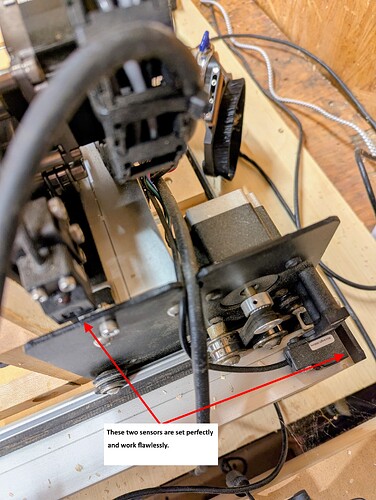

I posted recently about a related issue and decide to make this thread dedicated to this x-axis problem. I believe this started occurring after I installed the Z-Plus, and just started noticing the issue just recently. The carriage homes flawlessly at the top right corner like its supposed to. When I tell the machine to fast travel to any of the left x-axis limit positions, it crashes there causing a slippage of several belt teeth. The belt tensioning is fine and the adjustment of the x & y sensors seem to be perfect. Thinking it was a software version issue, I downloaded the latest version of Carbide Motion but the problem persists. See photos below.

When I started on the forum 6 years ago the Suckit Dustboot was very popular. They were bought by OneInfinity and it lost popularity on Shapeoko machines. The Suckit dust boot had ears similar to the ones I see in your picture. So when the setup was run you would have a little breathing room so the Suckit dust boot arms did not slam into the Y rail during jog. I do not speak for C3D but I think they have continued that until currently. During Jog only you can move only the specified amount from the homing position. With your pieces sticking out behond the edge of the Z-Plus the stock movement may be too much allowing your additions to hit the Y rail. You can adjust that for slightly less movement to the left by modifying parameters. During gcode execution there is no limit and you can slam the Z axis into the Y rail on both sides if the gcode commands the machine to go beyond the physical limitations of your machine.

All measurements are in metric. I have not modified mine in a long time so I will leave how to modify your parameters to someone else but it is possible.

Actually, those custom wood sliders for the Suckit Dustboot never touch the left rail. Yet, it still stops and the motor seems to run a bit longer causing the skip of several belt teeth. The image above shows the actuall stopping point. Note nothing is touching the left rail.

It seems you only have problems when you use rapid moves, that leads me to think that is how you may possibly be skipping steps?

Just curious, if you removed the X belt and belt clips can you move X all the way to the left and right?

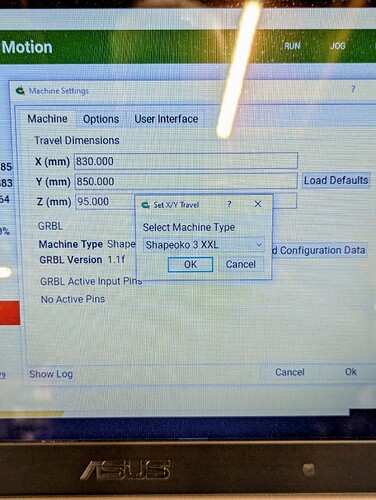

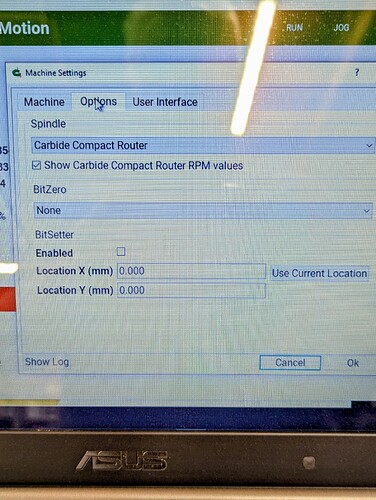

Okay so, I was originally thinking that I would make adjustments to the Travel Dimensions numbers for the X axis, which default to 830.00mm as shown in the image above. However, I have updated the Carbide Motion software to the latest version so now, I cannot find away to get to this dialog to set these numbers.

Does anyone here know how to get to this dialog in the latest version of the software?

BTW, I have adjusted the X endstop sensor as far as it will go and the left side X-axis is still going too far and causing a skip of several belt teeth. Does not only occur when rapid moving. I was able to reproduce this by manually stepping an 0.01 intervals.

The belt is also, plenty tight and is not worn.

Try turning off the machine and pushing it by hand. Feel around for any collisions. My guess is on the left side GT2 belt clip bumping into a V-wheel. There’s a small amount of variance in where it sits, so thats why maybe it doesn’t interfere on the right side.

As you’ve spotted in the settings panel (of the old CM version), you can manually dial back the travel. I’d do a 5-10mm reduction to be safe. On the newest versions, that box has been removed. You would need to open the “Data Directory” by clicking on the “version 6__” text at the bottom right corner of CM (after you’re connected to a machine). Then opening the .json file that corresponds to your machine, and messing with the values in the file.

I actually resolved the issue by modifying the JSON file and setting the X-axis Travel Dimension to -815.00.

This topic was automatically closed after 30 days. New replies are no longer allowed.