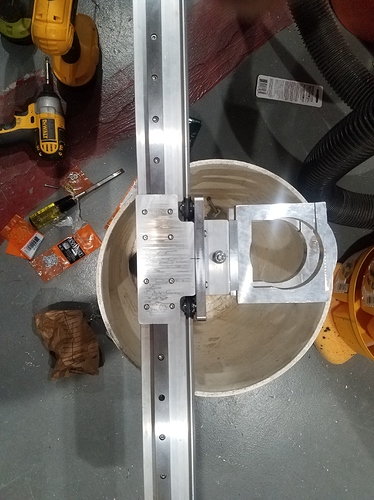

I installed a 15mm linear rail to the underside of my gantry and milled a plate to attach it to my new Z axis.

Thought about the same. Where are you noticing the improvements?

How come you kept the V wheels?

alignment purposes and I took the picture right after last bolt. I still haven’t taken them off because It doesn’t affect anything.

Cleaner cutting in acrylic, less striations and better tolerances held. I will be adding another up top.

It all makes sense to me

Out of curiosity how far away are you from making a new machine. Your rail project is where I started and it quickly escalated. Rather than use the shapeoko extrusions I opted to use larger T slot stuff.

LOL My 2000sqft workshop will be done this time next year, then I will (for fun lol) build a 4x8 ??

Do you have yours running under power yet ?

2000 foot! Are you kidding me?

Yeh mines all up and running - I thought I put a video up. I still have the dust collection and a few things to calibrate but waste board is surfaced… I also have a naughty 15w laser to attach

I like it - I think the addition of the linear ways and your linear Z address the two biggest weaknesses with the So3, have you tried it with aluminium yet?

Also, if you’ve installed a rail on the top of the gantry, how did you go about the V-belt location?

Looks awesome!

How did you drill the mounting holes for the rail in the original rail precisely enough to keep them parallel? Or are the holes in the new linear rail large enough that you have play and secure it after the fact?

Thanks all,

The rail for the top will be in next week and the plan is to notch the plate to fit around the 2 pulleys in the middle.

I mounted the plate to the Z axis plate ran it to one end and clamped it, ran it to the other end and clamped it. Ran it to the middle next to a hole and drilled tapped and inserted bolt, moved down 2 holes and repeated.

Wow, your shop is bigger than my entire house, garage included! I’m attempting to fit an XXL, band saw, planer, jointer, miter saw, dust collection, work bench, plus my fishing gear and various other items into about 375 square feet of space, maybe less. I need to lose some weight just so I can squeeze through my garage/shop.

These types of carts work great for small spaces. You can flip it when you need to use the router table. I have my planer and my sander on another cart.

I have an XXL, a 4’ Laser 2 big tool boxes, compressor shelves, etc… in 500 sf.

I have been looking at swivel carts and how to make them. Your space looks about the size of mine, except I donated some space in an extra adjacent room to my XXL. I have a whole lot more s— in my garage though.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.