Anyone else have an issue with wire crowding in the electronic enclosure?

I have a new machine XXL with Z axis Lead Screw. (New as in less than a month old and have been completing the assembly in my spare time)

Completed assembly about a week ago, jogged it around the table and everything was good.

Came in the next morning to run a few simple files just to watch it move. Machine fails to initialize.

Hmm ok…Zaxis proximity switch is not registering. I immediately start checking wires for loose connections or breaks. I find nothing then I decided to open the electronics enclosure just to check that out. I immediately see a dangling wire. So I’m looking at it and wondering why it just fell out of the connector.

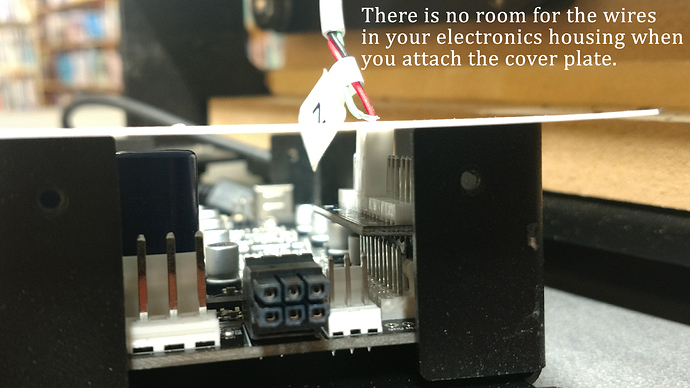

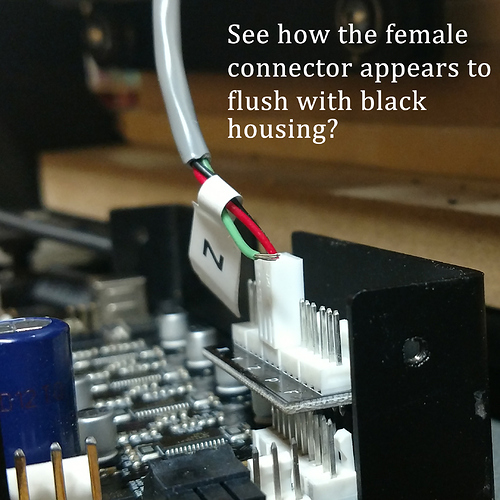

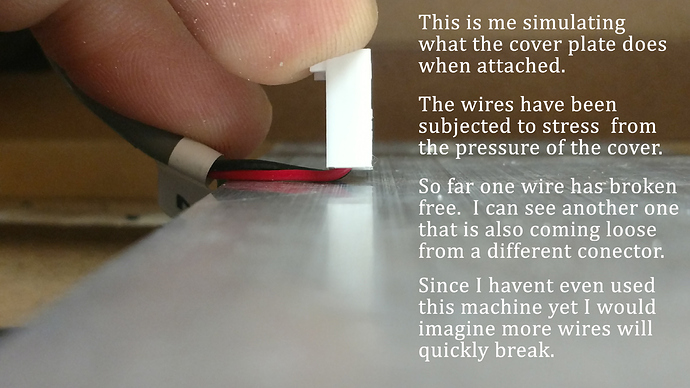

When I actually looked at the electronics enclosure I found that when the cover is in place it actually smashes the wires on all the proximity switches. Easier just to show pictures that I sent to support. .

I emailed support and got a pretty unhelpful answer telling me it was a bad connector and they would send me a new one. The problem might partially be a bad connector but a bigger issue is the fact that the cover plate is bending all the wires and putting undue stress on them.

I thought maybe I had received a bad part, maybe the electronics housing was accidentally cut smaller than normal or something. A couple follow up emails have not been answered which is starting to annoy me.

I offered to build my own cover plate. I am concerned about more wires coming loose at a later point so it seems like a good idea to replace all the connectors that were bent over because of the cover plate.

Thoughts. Ideas. Suggestions.