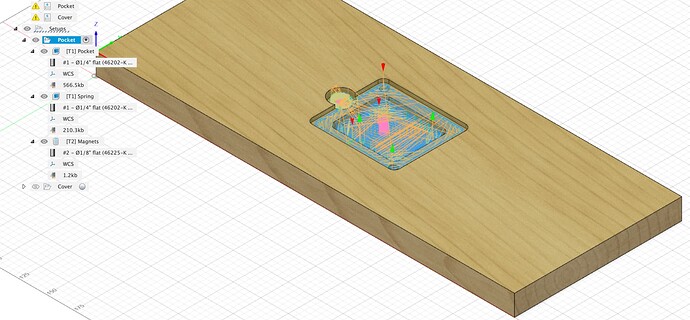

I’m cutting this pocket using the 0.25" Amana 46202-K Downcut 0.125" 46225-K Downcut tools.

I’m using 3D Adaptive Clearing and there seems to be a large amount of time sent in milling the circular hole on the left side of the pocket. I tried a boring operation but that left a cylinder in the center of the pocket.

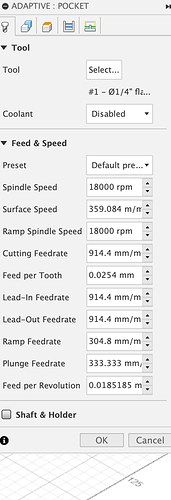

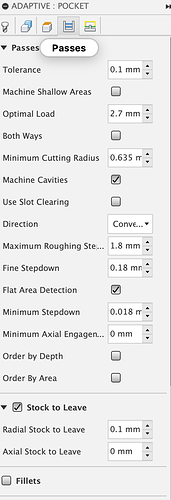

Here are the settings for the first operation:

Any thoughts would be appreciated.

Thanks,

kelaa

January 23, 2022, 7:18pm

2

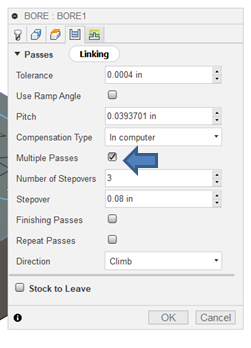

If you want to continue to use Bore, you can manually increase the number of stepovers until it removes the core:

@kelaa Thanks for the tip, I didn’t see that option.

I just switched from 3D adaptive to 3D pocket with feed optimization enabled and that has reduced the time to 10 min operation with the tool change.

system

February 2, 2022, 6:30pm

4

This topic was automatically closed after 10 days. New replies are no longer allowed.