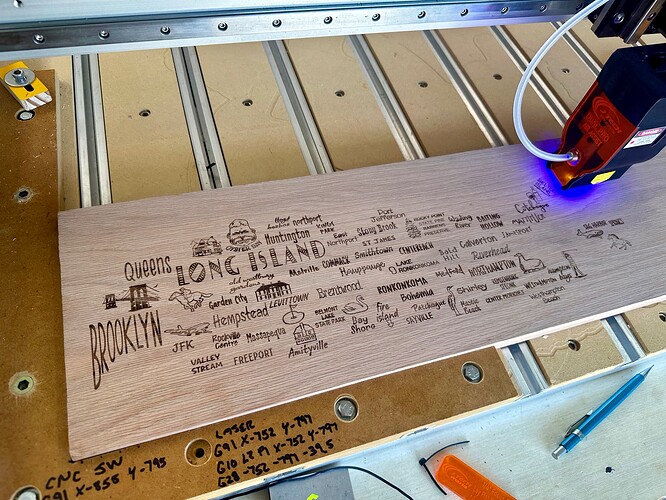

I am new to CNC. I started first with a diode laser, and recently dove into this Shapeoko world.

After getting to know my CNC, I’m realizing how important my laser is in the workflow. I will preface this statement with the fact I know nothing about modifying a Shapeoko or similar CNC to do laser work. (thought I’m super interested in how the z-axis could come into play to perhaps laser engrave depth maps, but that’s for later).

If space is your limiting factor, I understand adding a laser module to your existing setup makes sense. But I think the benefits stop there.

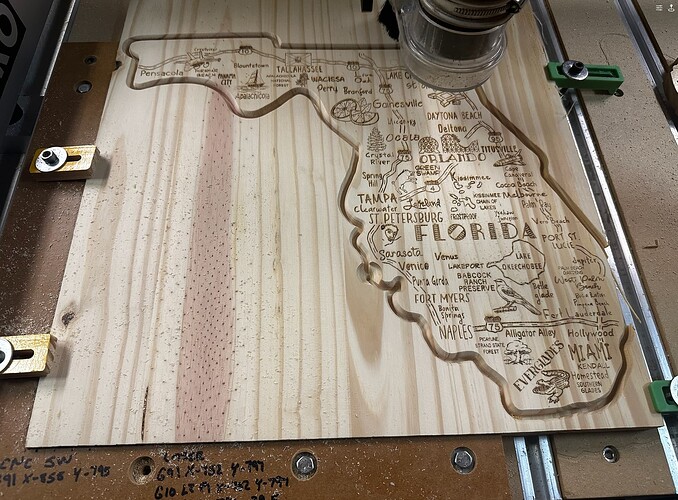

I literally just got back from de-greasing my laser bed after about 30 hours of it running. Not just the honeycomb but the metal bed beneath it.

This is very significant to the topic, because the first thing I realized when i starting running my diode laser was it needed an enclosure and it needed ventilation to the outside. My studio smelled like a campfire within a day or two. That’s all well and good and many CNC owners make enclosures for their tables as well, but for very different reasons.

The residues that end up on my base plate and honeycomb are crazy. I cut sign paint/enamels, and standard acrylic painted wood, as well as stained wood. It’s like cleaning an old brass weed pipe from the 80’s. Goopy, oily resin that ends up everywhere. The walls of my enclosure, my ventilation needs a filter and it still doesn’t stop the oils.

My point is I don’t want to add this sticky, goopy element to my amazing Shapeoko. Any enclosure I build for the purposes of keeping the sound and dust down for its initial purpose does not instantly translate to having a proper enclosure required for a laser.

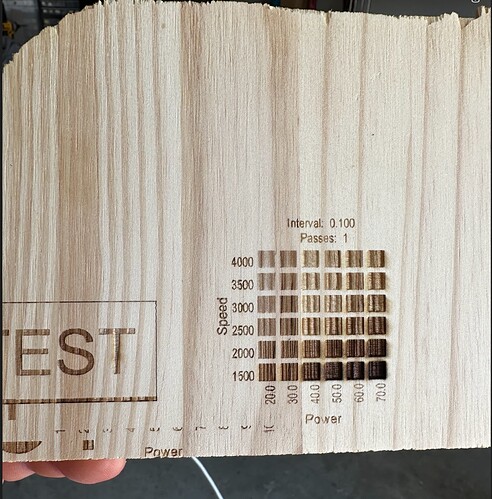

Last week (after spending about a month looking), I got an open-box X-Tool D1 Pro 5W. Totally un-used (you can tell by the lack of any goop), for just over $300. This is my 2nd X-Tool machine and because I upgraded from the D1-Pro 20W to the 40W, I can get the 5W used and frankenstein them to make 2 lasers with 3 modules between them. The 5W in my new shop now has room for me to use the extension kit, thereby doubluing my template size.

Benefits of individual laser :

keep gunk out of your precious and much more costly Shapeoko

get a much better machine

be able to cut both laser and Shapeoko simultaneously

[edit] Lasers cause fires, has its own safety requirements [/edit]

Drawbacks:

more expensive

more room needed

you get to learn another software (though Lightburn beta now can control CNC but i haven’t had the time to check that out).

Good luck!

edit : I was literally cleaning my laser cabinet when this thread came across, so I took some before and after photos showing the oils on the wall of my enclosure (all the other sides are cabinet plywood, and not as easy to see the oil but it’s still present). I sprayed a little degreaser and used a shop towel and check out before and after. Unfortunately, the other shot is my toxic dump where I spray as little degreaser on the metal sheet/bed of my laser, let the water evaporate, scrape out the residue and bring it to our hazardous waste at the dump and they look at me like an idiot because most people just toss this stuff. Anyways, please don’t bring a lot of this into your precious CNC when you can run a decent laser for $500 all-in

The oil is on new drywall that is not more than 8 months old, and I constantly clean it. I decided to swap out the 1/2" drywall that the closet came with for 5/8" fire rated drywall. Plus a special fire retardant spray across the entire wall and cabinet. Look at the image where I only cleaned half of the drywall

I’m not saying this residue is a bad thing, but I also am not letting it anywhere near ball screws on my five thousand dollar CNC.