WillAdams

January 28, 2021, 2:28am

8

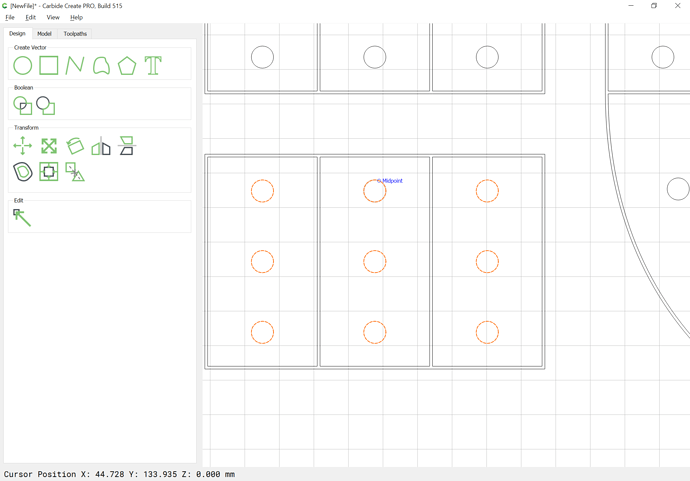

Select the geometry which you wish to cut as holes:

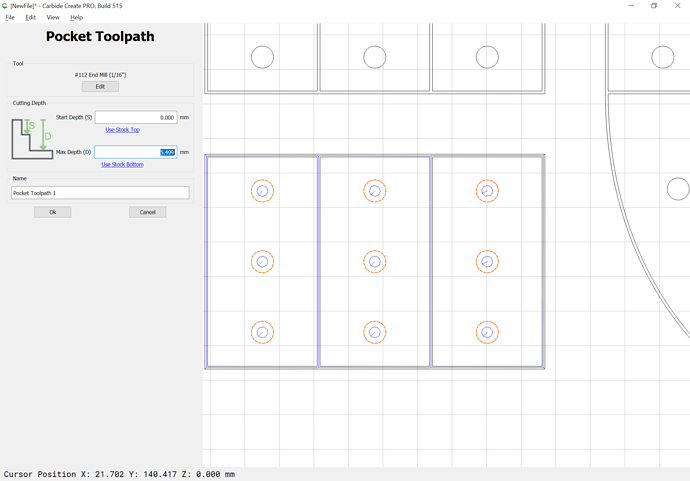

and assign suitable toolpaths:

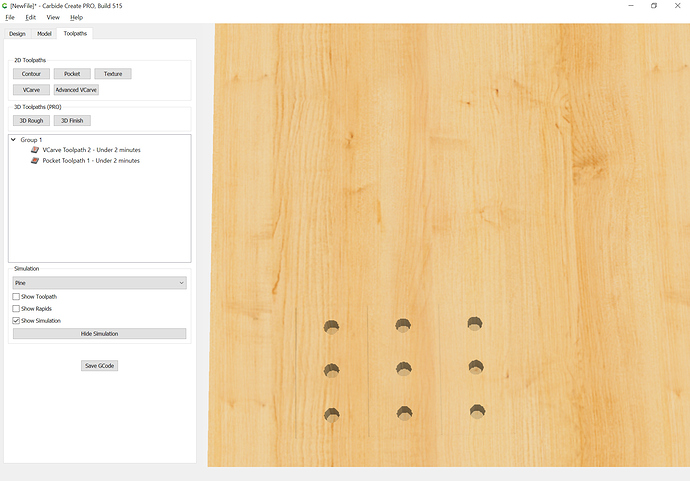

Repeat for all the geometry needed, then add geometry around and cut as a pocket down to tab depth and finish the profile, if desired, adding geometry for a roughing clearance and taking a full-depth finishing pass:

One technique which is often suggested to avoid slotting is to add geometry around a part which one wishes to cut out and cut as a pocket down to tab depth — here’s one technique for that.

In this case, the project is a bevel gauge which will be cut out of 0.0625" (~1.5mm) thick aluminum:

[bevelgauge]

Due to the narrowness of the angles, an 0.03125" endmill has to be used, so after importing and scaling the file (we will be cutting out one which is 3") we select the perimeter and offset it tw…