how did you do the embedded video?

Post your video to imgur then copy paste the link here.

ah i was hoping i was missing a way of just embedding it. i usually open my google photos tab, and copy/past images.

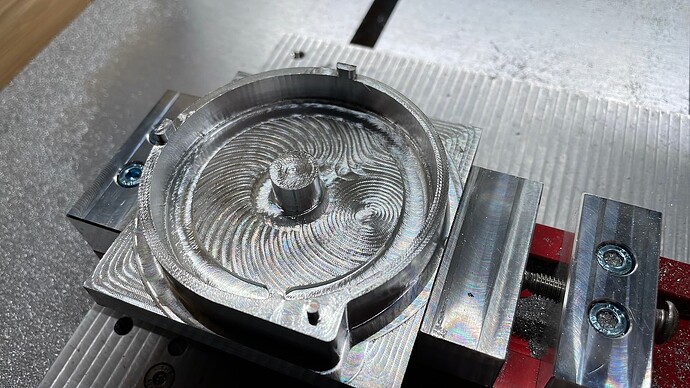

You nailed it! Low DOC and wide(ish) stepover is absolutely the way to go on this machine. Only thing I did differently was use a 5mm 3-flute endmill at 20000 rpm with 2500mm/min feedrate. Machine was still sort of happy at 200% override, so 0.15mm DOC 1.25mm WOC 4800-ish mm/min. I think the extra rigidity of the thicker tool helps when flat milling like this. Machining time was about 20% higher than with a deeper DOC/low WOC strategy (I tried a whole bunch this afternoon, can’t remember the exact values, think it was 2.5mm DOC, 0.2mm WOC around 1500mm/min) but the machine was clearly a LOT happier. And so are my neighbors, presumably.

Here’s the initial results. Vertical walls have been finished with stepped 0.1mm DOC multi-pass 2D contours.

Also, turns out I was very much milling 7075 instead of 6061. That explains some of it as well.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.