Hey you folks out there with Lube Cubes, do yours fall off your machine after a few minutes? Or is just me and my setup?

A short video to show the issue.

I dont have one of those but I would say from the sound of the cutting you have some vibrations going on and if it is just a magnetic mount not much will hold that way. If you do a lot of machining with that setup Try adding mounting screws to the setup.

Anthony

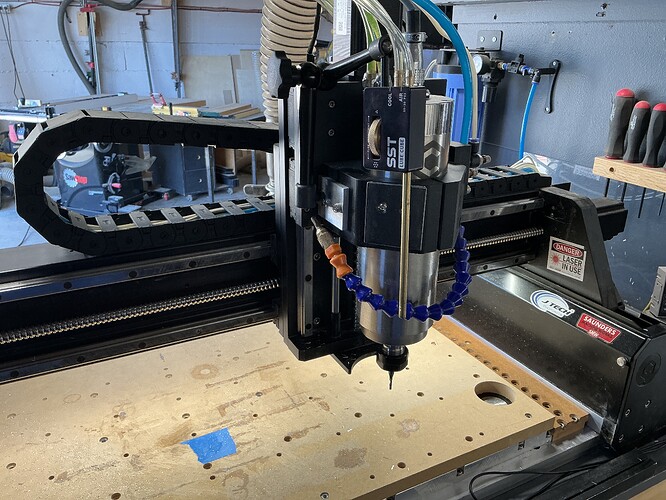

The adjustable arm is likely attached to the mag base with something like an M5 or M8 thread. You may be better off making an adapter that you can bolt directly to the spindle mount instead of relying on the mag base and friction. In lieu of that, maybe you can scuff up that steel plate or plastidip it to make it less slippery.

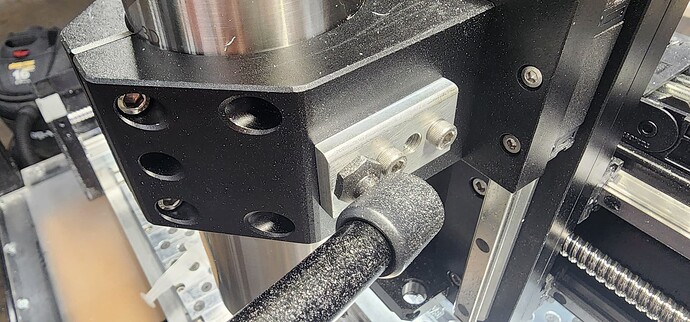

I agree with @wmoy in that making a plate to bolt the arm directly to the mount is far better. It’s how I attached my SST setup.

Yeah, I thought as much. I’ve been putting it off since I haven’t been doing a lot of aluminum until recently. Not crazy about all that hardware hanging off the front of the spindle mount all the time.

Mind sending a pic of your setup?

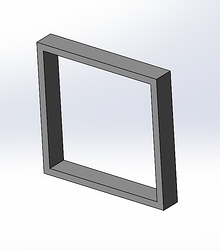

Could you potentially print or mill a ring that could friction fit/glue onto the magnet that the Cube could slot into? Would be thicker than the magnet with a bit of extra room for the Cube to mate with. Might prevent the gradual shearing when cutting?

Hmmm, hadn’t thought of that. I’ll print one up.

Thanks!

Perfect, thanks!

Too simple for me to think of, so easy for amateurs to complicate designs.

Trust me, it’s WAYYYYYYYY easier for professionals (I use that term loosely on myself) to overcomplicate things. ![]()

Well, not this one. I mean you even only chamfered two edges!

That’s because it was extrusion that already had filleted edges. ![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.