Looking at investing in Pro XXL, i have had some experience programming and running CNC machine tools, but that was 30 years ago. I am a journey level cabinet maker.

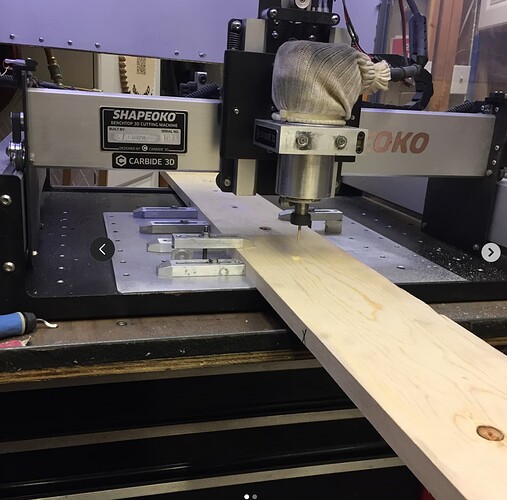

My initial projects are simple, but dimensions are roughly 18” x 60”. Im interested in creative ways you all have done this. Thinking extending out one end (with support), with a long 60” straight edge reference fence in the Y direction. And then be able to move the workpiece along that Y reference point (extending out the other end, and then finishing the machining on the other end of the workpiece. Anyone with success doing this? Pictures ?

Yes, folks have done this — usually folks put a series of holes at the corners, w/ an overlapping seam at the middle section(s).

A lot of folks use dowels and holes when doing jobs that require moving the workpiece. Either tiling it our flipping it over to machine from both sides. You can clamp a piece of scrap down along one side and use the machine to cut it and then have a full length fence that’s perfectly square to the machine. Then over on the other side machine a couple holes along the Y axis. Put your stock down and run your job to cut the first “tile”. As part of that job, have it machine 2 holes over on the side that will match up with the other holes you made earlier when you go on to your next “tile” position.

Once you job finishes, slide the stock along the Y axis and when your 2 sets of holes line up, press a couple dowels through them to lock them together. Run the second “tile” of your project. Rinse and repeat. As long as there are more tiles of the project remaining, keep adding dowel holes.

Once all the CNC work is done, you can run your 60" long panel over your table saw and trim off the strip with the registration dowel holes.

I have seen folks use allthread for similar purposes. Cut a nut in half and glue/clamp a piece of allthread to your board. The half-nut can be used to help register on the allthread to move it a precise distance. If this is a project you will be making multiple times, you can make yourself a fixture sled with allthread on it to help move it exactly the correct amount every time.

This method is refereed as tiling. The CC software does not support it. Vetric Vcarve Pro does support this feature. The Vetric Vcarve Desktop is limited to I think 24" x 24". There a lot of work around for this here on the community site. As stated above it is usually by making reference holes so when you move the project up you have a reference to cut from.

It’s very easy… and I do this often (since I only have a S3 machine)

I do it two ways.

- If the board that I am cutting is pristine (meaning I or the customer) does not want to put tooling/index holes, I use an index board (prepared tooling board that I have in stock)

- Place the index holes in the back side of the board.

Ref:

Note: I have a few items here on making my Chippendale Desk legs if you search for them. (tooling holes)

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.