hi

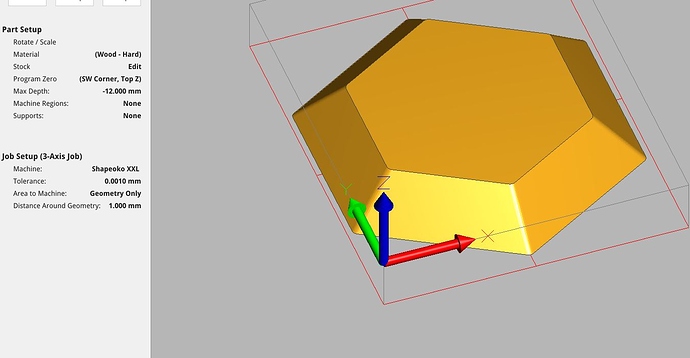

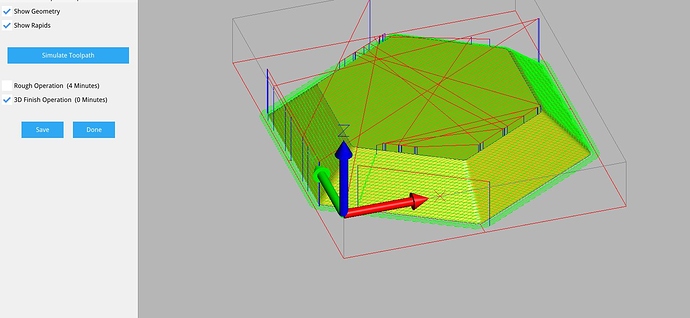

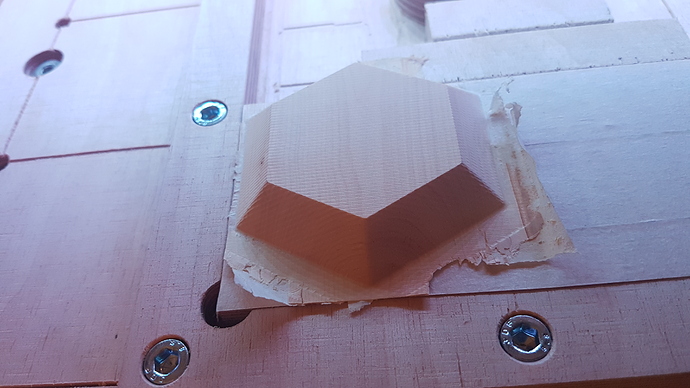

I join a machining that I set up on meshcam version 8. The machining went well, but I have two questions… to understand the behavior of the machine.

you have to test the program on the machine to find out.

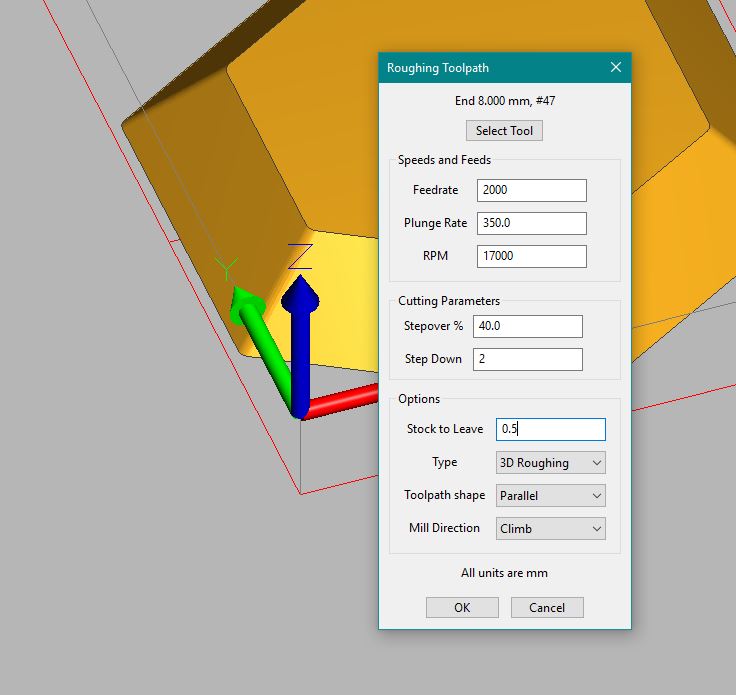

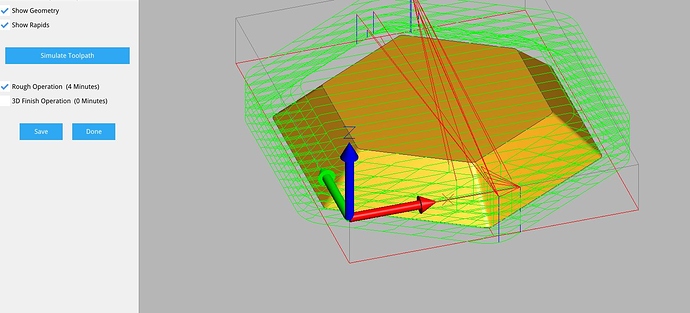

On the rough machining, the machine slows down in the corners of the hexagon, while it machines correctly at my settings for the rest.

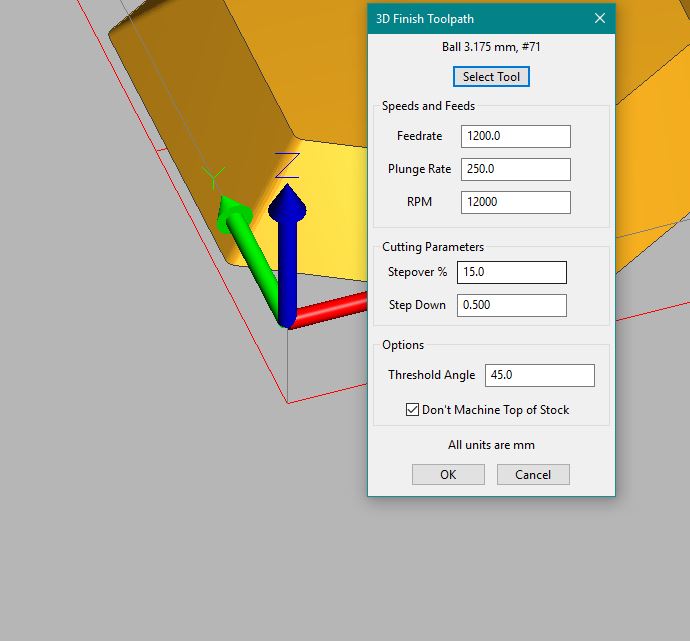

And for the finishing, and starts and ends with a “little brush cleaning” in places that are not very useful on this project.

I made an 8mm endmill roughing run, and for the finishing, I used a 3.17mm ballmill (unified finishing).

I wonder if it’s normal, or if I set something wrong…

is there a difference between the choice of the machine, carbide 3D shapeoko/ XL/ XXL.

And what does “distance arround geometry” correspond to ? I did some tests with 1 mm and 6 mm and I saw that it influences the tool travel…

hexagone 3d.mcf (106.4 KB)

thank you

vivien