I have a customer asking me can i cut small shapes out of a metal that magnets will stick to. Does anyone know off hand magnet friendly sheet metal? And something that is doable on a pro 4? I was thinking stainless steel but im not sure that will work. Many thanks.

Folks have cut stainless steel — but it requires an alloy suited to machining which is in an annealed state, and getting the feeds and speeds just so (and using coolant).

12L14 steel is supposed to be one of the easiest to machine, but check about work hardening.

Just avoid austenitic stainless steel. Ferritic and martensitic stainless steel attract magnets - for the most part. There always seems to be an exception to every rule.

Real Stainless Steel is not magnetic. However many “Stainless Steel Alloys” are magnetic. So real stainless steel will not attract a magnet. So you would have to research which alloys will attract a magnet.

This was a quick google search of “Why stainless steel does not attract a magnet”

Most stainless steels falling under this category are non-magnetic because they contain high amounts of austenite. Even though some of the metals like grade 304 and 316 have iron in their chemical composition, they are austenite, meaning they are non-ferromagnetic

The Shapeoko can cut some steels, but the relatively high RPM of the spindle means you have to use tiny endmills. Tiny endmills means going slow. Slow is the enemy of productivity.

This may be blasphemy, but for sheet metal work that’s more than a simple one-off piece, you should consider your time invested into trying something that may or may not work, requiring hours of learning and experimentation, and causes a lot of stress, vs outsourcing it to one of several online laser cut metal services on the market. I can justify going through some inconvenience to knock out a prototype ASAP in the comfort of my garage. But if someone’s asking me to make dozens of something out of a flat sheet that I can have laser cut for like $40, I’m just gonna outsource it.

I appreciate all the relpies so far, thanks. Doing a little resarch and it seems 430 alloy SS should be very conductive to magnets, just have no idea how well that would machine. Im not trying to do anything fancy, the customer wants small discs out of thin sheet, something like .064". I almost always use single flute 1/8 bits when cutting aluminum, would the same apply to SS? Or should i be looking at different endmills? Also, anythoughts on a starting point for f&s’s?

The screwdriver I dropped in the canal while working on my boat lift was, fortunately for me “magnet friendly”! ![]()

It didn’t sound like “stainless” was a requirement, so I’d go with an easier to machine alternative like steel A36, 4140, or the 12L14 Will mentioned. They can always be polished & coated if they need to look nice & shiny.

I’m with Winston with the “outsourcing”. Can he make something like this work?

Thanks for the find, i’m definitely going to see if my customer can make something like that work. Even if i could cut these out, i couldn’t do it for anything close to those prices.

I’ve had good luck with mild steel. It makes an awful noise when you cut it. I have used 1/8th bits and I can cut pretty fast. It is a lot more fussy than aluminum. I use a bit of WD-40 for lube. All the same advice goes that you use with aluminum: Be careful of slotting.

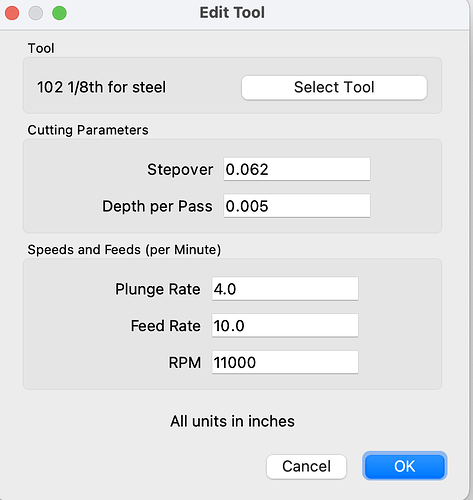

I’ve attached my parameters for an 1/8th bit.

Good luck

This topic was automatically closed after 30 days. New replies are no longer allowed.