WillAdams

(William Adams (Carbide 3D))

1

as requested on support…

…make:

-

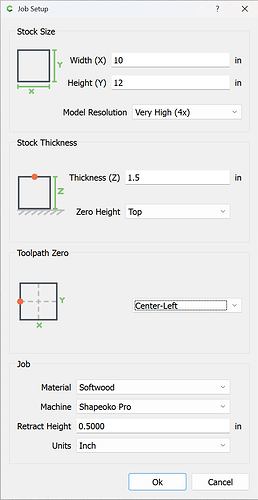

Board size = 10" x 6" x 1.5" (thick)

-

Product size = 8" x 4" x 1.5"

-

Cut bowl size = 7" x 3" (upper lip)

-

Bottom of bowl = 4" x 1.5" ; 0.25" thickness remain at bottom.

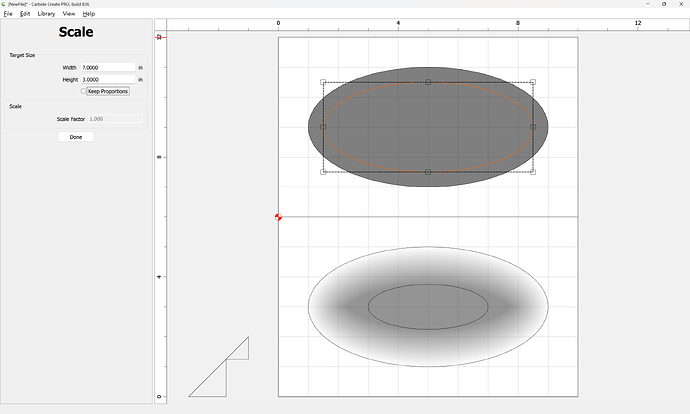

The file will be set up at twice the necessary size so that top and bottom may be cut in separate operations:

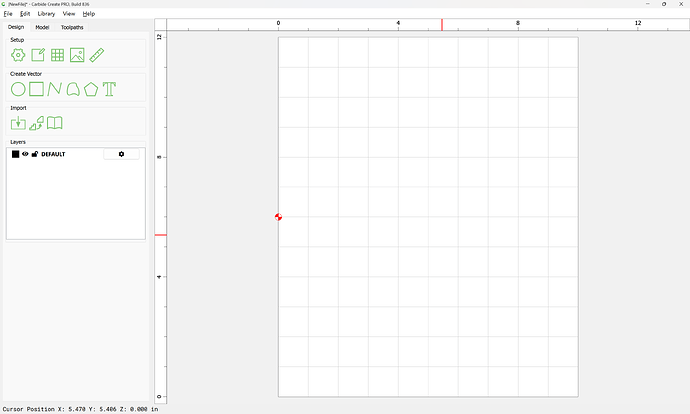

Draw in geometry for each half:

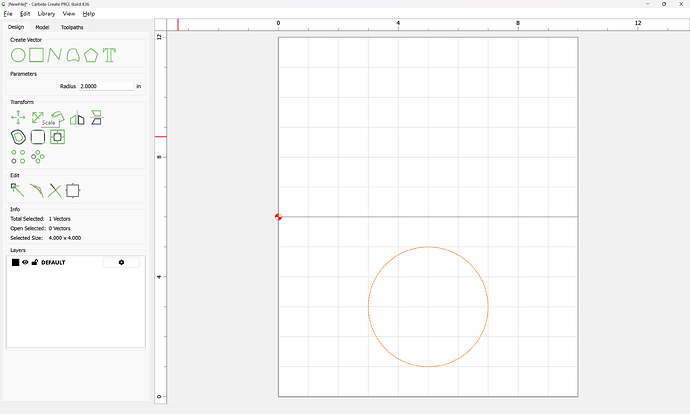

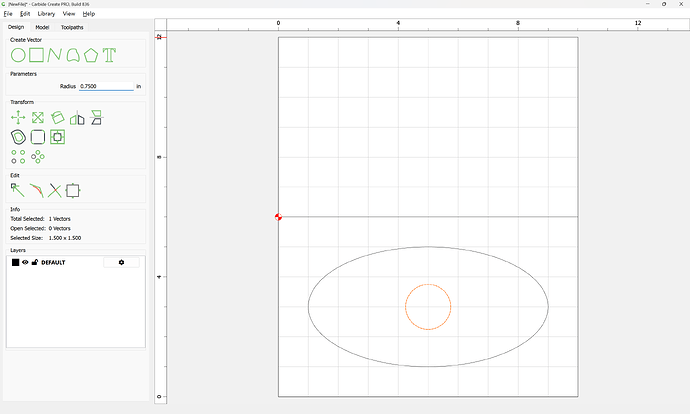

Then draw in a circle:

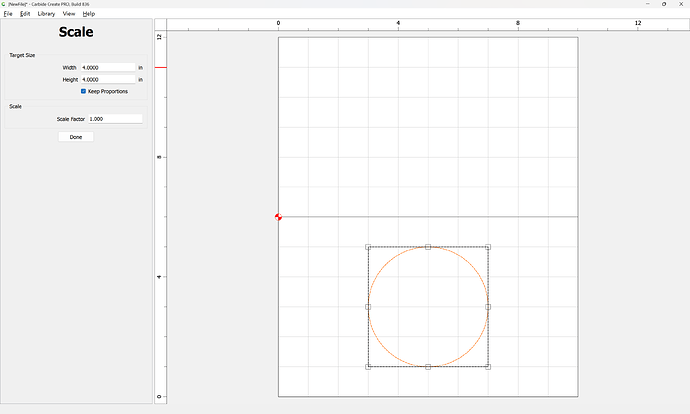

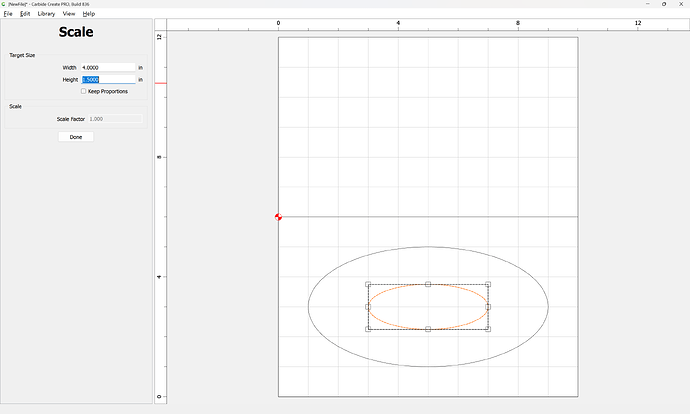

and scale:

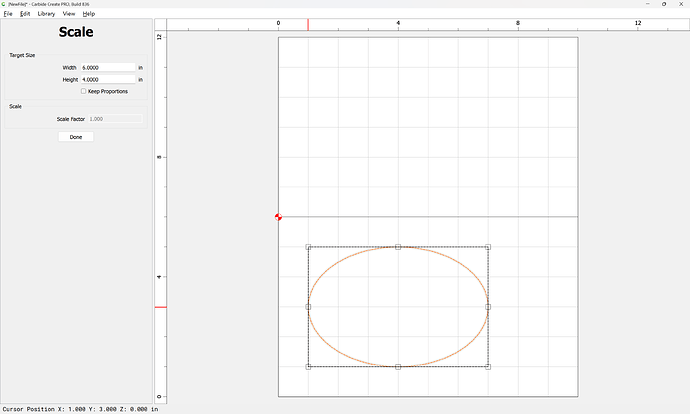

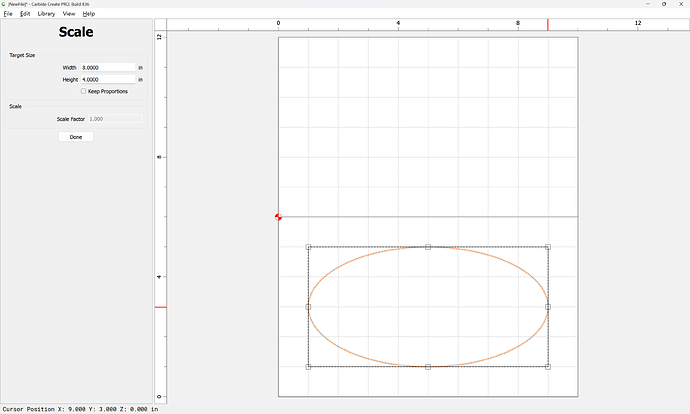

clear the checkbox for Keep Proportions:

to draw the outer perimeter at the top.

WillAdams

(William Adams (Carbide 3D))

2

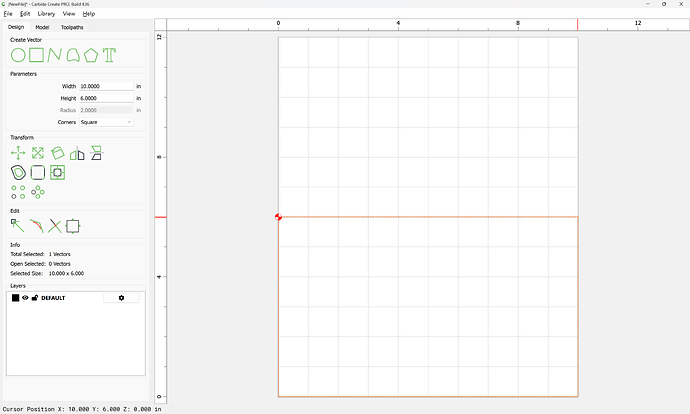

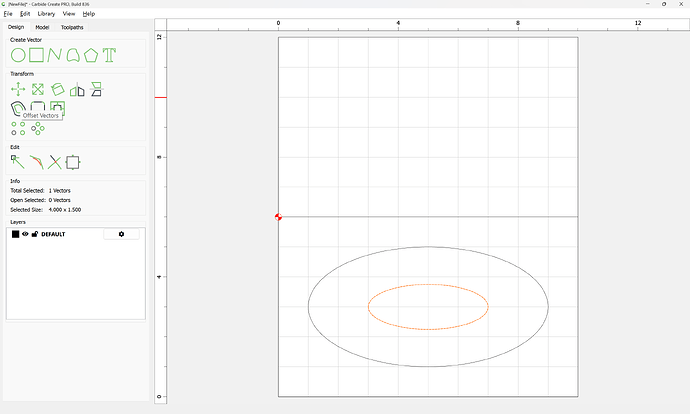

Draw in a circle for the bottom:

and scale as before:

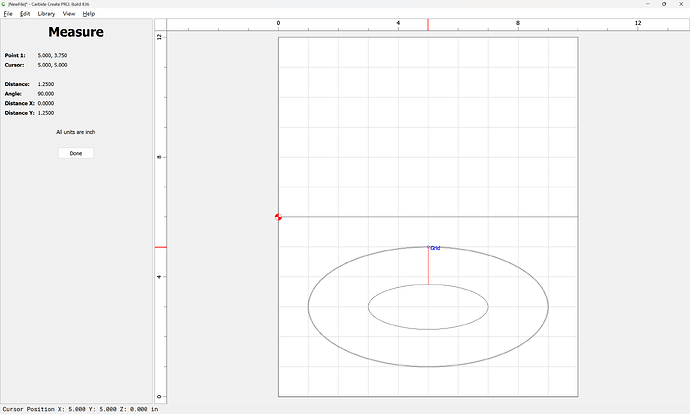

Measure the distance to the edge:

but it is not possible to inset by that dimension:

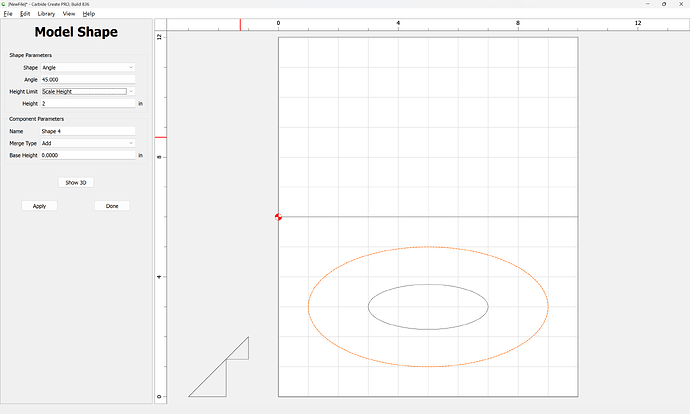

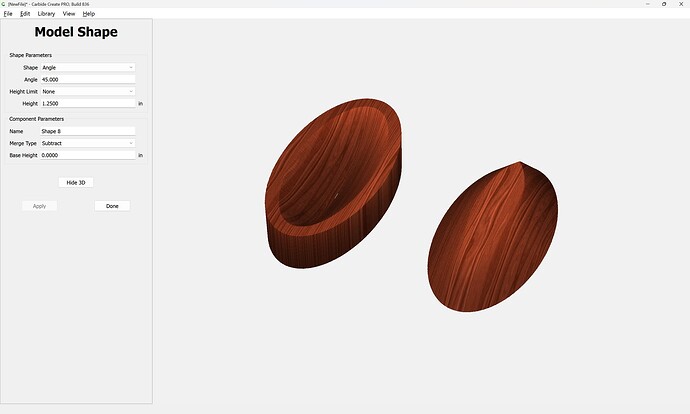

So instead, draw things up in profile:

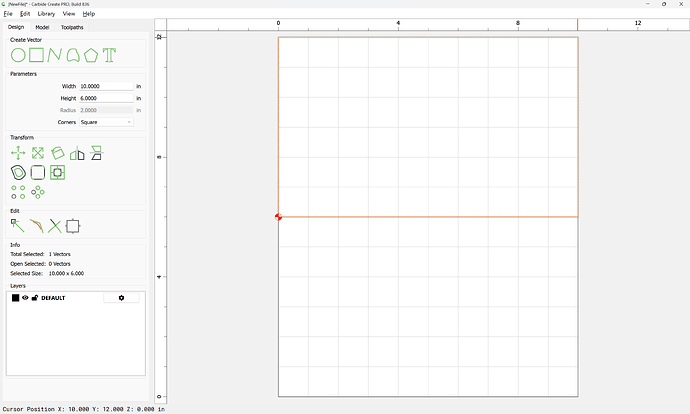

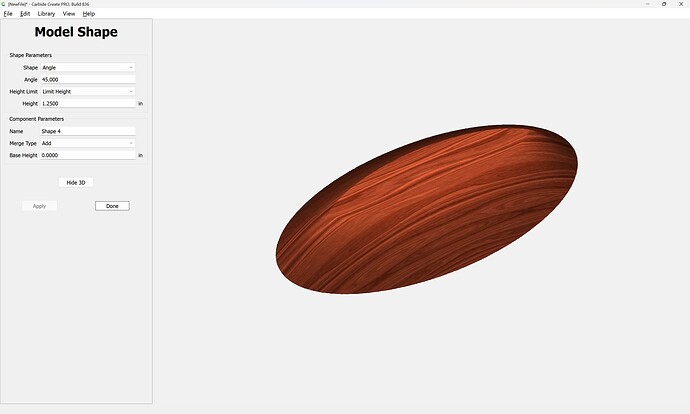

and model to that height:

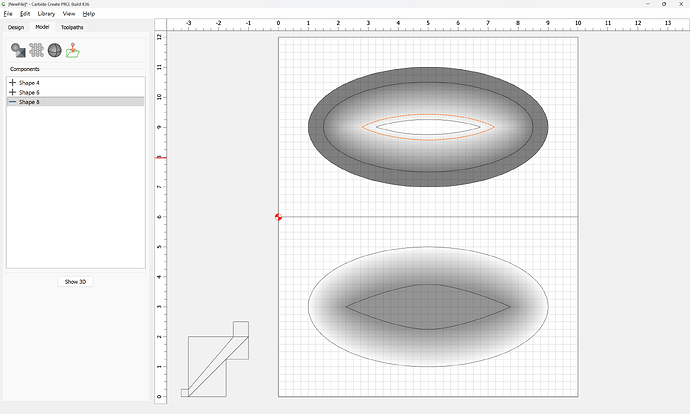

Edit the model to match:

(though note that the model no longer matches the specified dimension)

WillAdams

(William Adams (Carbide 3D))

3

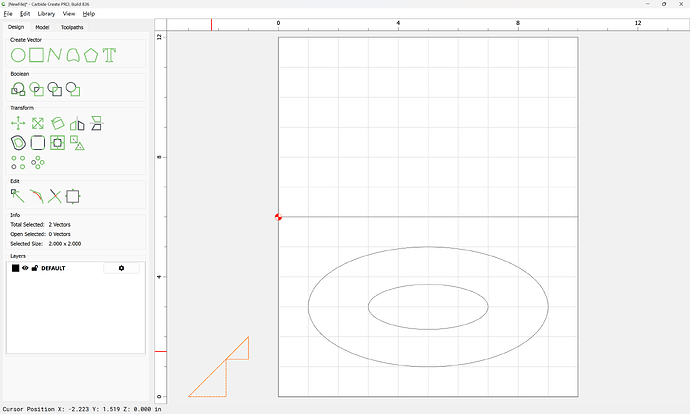

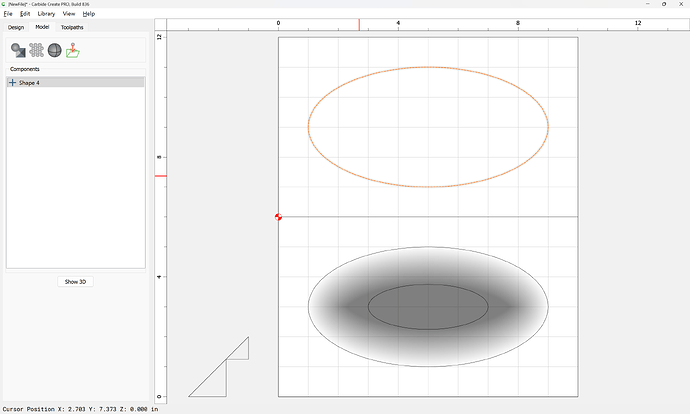

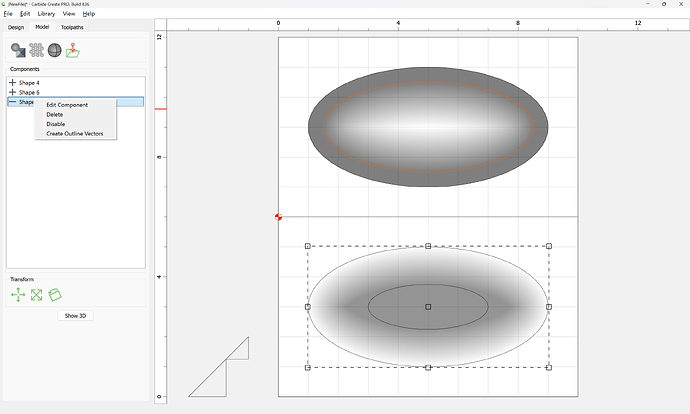

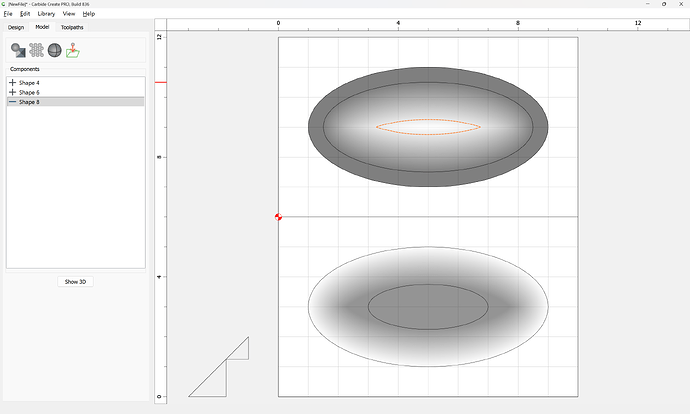

Copy the perimeter outline into the top half:

and model to the full height:

Apply

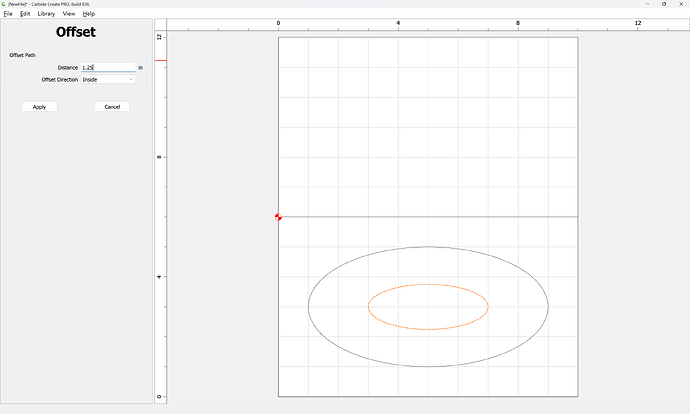

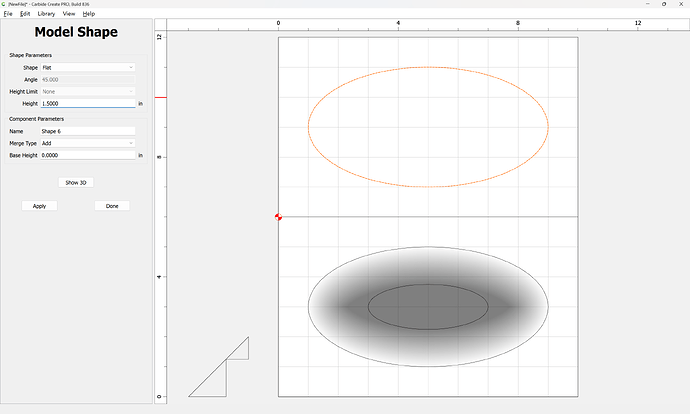

Then draw the inner perimeter:

Then use this geometry to try to model the interior of the bowl:

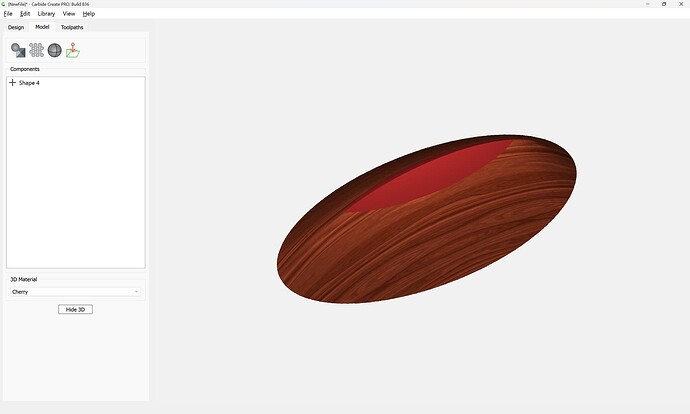

and check where the model is:

and adjust based on that.

WillAdams

(William Adams (Carbide 3D))

4

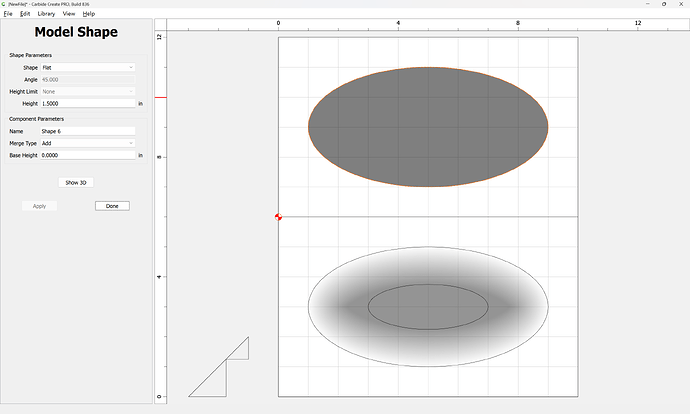

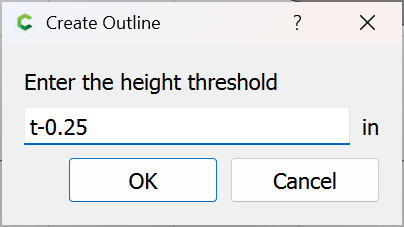

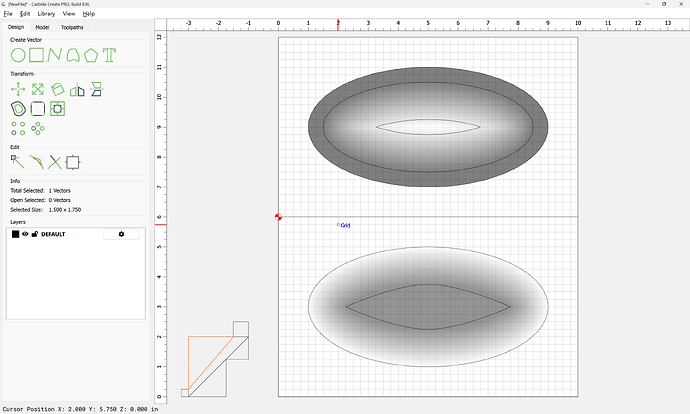

Drawing up in profile we get:

Adjusting a bit:

then tracing we get:

which looks to fit within the outline.

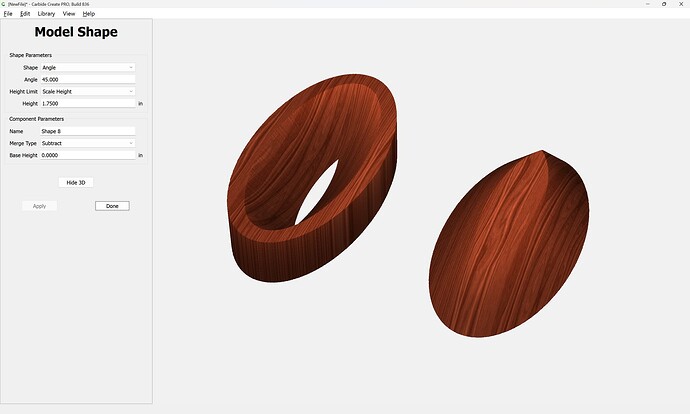

Then model this as an equal thickness:

Attached as a v8 file.

bowl_v8.c2d (1.0 MB)

system

(system)

Closed

5

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.