@CrookedWoodTex for the win! I traced the blade and used that tracing to make a rough-ish polyline in CC using this method. I then used “offset vectors” +.25" to create a pocket I knew the blade would fit in. I left the large circle in the blade untouched. This created a HUGE pocket for the blade to fit in with one constant feature, the Trademarked “Spyderco Round Hole”. I did this for both sides of the blade on a single piece of 1/2" starboard. With the pocket carved I placed the knife in the pocket so it would pivot on that single huge hole in the blade. I roughly centered it in the pocket and marked the next largest hole, the one the blade pivots on, and drilled/tapped that. Now the blade has a jig it can fit in and will always be in the same position relative to X/Y zero (front/left) of the jig. I also drilled and tapped 8-32 set screws from underneath to support the blade near the sharp side.

Next step was to locate the blade within the jig. I placed the blade in the jig, set my X/Y zero to the lower left corner of the starboard stock using a 30* bit. I then jogged to the blade tip, and wrote down the coordinates. Moved right .3" and jogged north along the Y until the point of the bit was at the upper edge of the blade, wrote down those coordinates, rinse and repeat every 0.3". Did the same for the lower edge. Now I have known coordinates of the blade relative to the stock’s lower left corner.

Armed with those coordinates I return to CC and loaded the file for the pocket cut. I then make rectangles using the X and Y coordinates I recorded for height and width of said rectangle. I drag the lower left corner of each rectangle the lower left corner of the work space. I then draw another polyline from the tip of the blade coordinates to upper right corner of each rectangle. Now I have an accurate shape of the blade as it is actually located within the jig. Bit of node smoothing, some adobe illustrator wizardry, and I have a jig and template file I can use for repeatability.

I really appreciate everyone that chimes in with help on all my posts. I try to make it a point to go into detail how my problem was solved. If any one has any questions I’m happy to answer.

Final jigs:

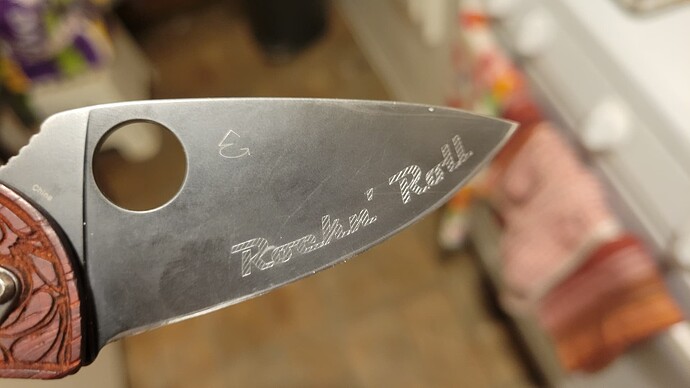

First engraving: ignore the “N”. That was me just dragging the bit across the blade to see iff it would make a mark. This knife is one of me EDCs, so the blade has some wear on it already.

Thanks for reading!

CC file for