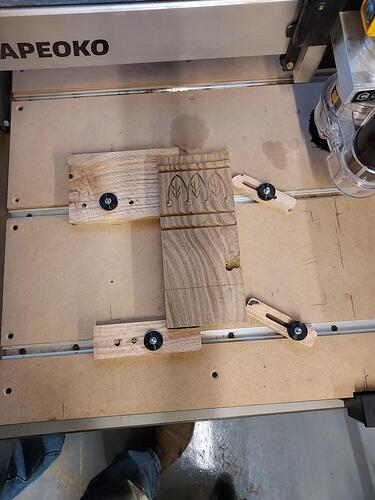

I have it pretty close to being acceptable. A few issues with the toolpath for the leaves, it includes putting a center in the circles and an X shaped groove at the top even though those areas aren’t part of the vector. I don’t understand why they are added to the toolpath. The actual leaf is hardly noticeable, very shallow, but it doesn’t change when I try to change the depth in the toolpath.

Plinth Block 9-23-24 V3.c2d (88 KB)

You included the circle in the V-carve toolpath, and again in the drilling toolpath.

I would make the top rectangle wider to it cuts past the edge.

The leaves won’t get any deeper with a V-carve. It positions the tool at the depth where it touches both sides of the vector. To go deeper, use a narrower V-bit, or edit the vectors to be wider.

Thank you, for your advice

Plinth Block 9-23-24 V9.c2d (92 KB)

. I think I have it where it is acceptable.

Roger: I think all depends on the tools at hand. I have to make some chessboards for the chess club in the cafe of my family, cutting a really straight piece to glue it really seamless(!) together on a table saw is something I cannot do. I just have a Sawstop tablesaw, the least expensive, and no cutting sleigh, no need to make one, need it not often enough. However: I cut the pieces with the CNC crosswise. And: to flatten the surface of course a planer will be the fastest and best solution. But a standard chess board is 5cm per square, makes it 40cm (16 inches) wide. Such a planer is not really cheap to get, I rarely need it, and I do not have a huge hall available just some basement. So I use what I have, the CNC. It flattens the surface very nicely. Yes, it takes forever. But eventually it works, and I can do other work while the CNC runs.

Sure a band saw would make a good job. But again: space. The CNC uses a lot of floor space. ok. But can be used for several tasks I would need several machines for otherwise, in that example a planer, a not too small table saw, a jointer and enough space around them to work safely(!) with them.

Of course I adore people that can perform precision work without the CNC, real craftsmen. I have to admit: I started woodworking with age 60, never learned how to work precisely like the neighbor carpenter who makes the best kitchen furniture I ever saw in my life. So I have to substitute craftmans precision with CNC precision. Works. For me. And: real craftsmen use tools. CNC is one of them. Just a tool.

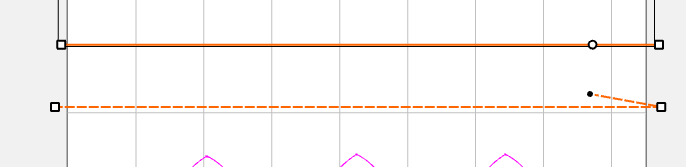

I have a small issue with the right side of the top groove having a small jog in it. I’m assuming all three should be the same, but the toolpath acts differently on the top groove and it leaves that side wider than the rest of the groove. Thanks.

Your top 2 open vectors have an extra node, and the vector doubles back on itself. Delete the extra node.

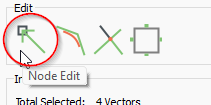

I’m not seeing the nodes. What do I need to do to see them? Thank you.

Sorry, I figured it out. Thank you.

Select the vector, and Node Edit

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.