as requested on support…

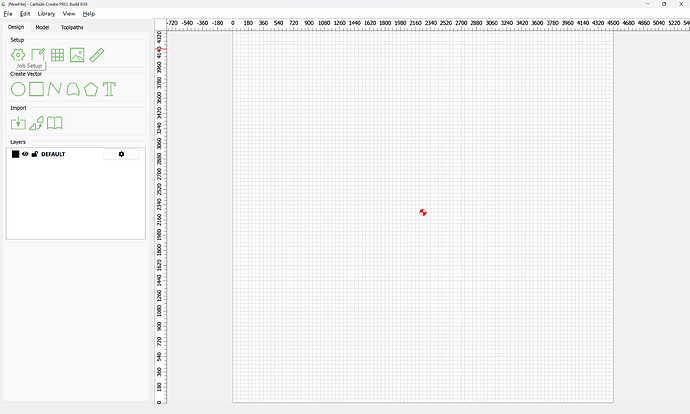

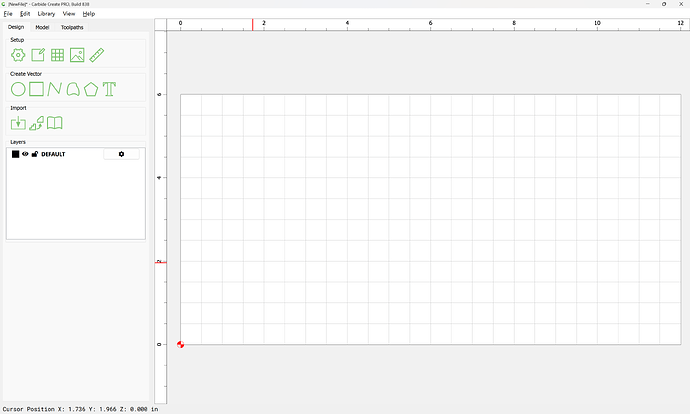

Launch Carbide Create:

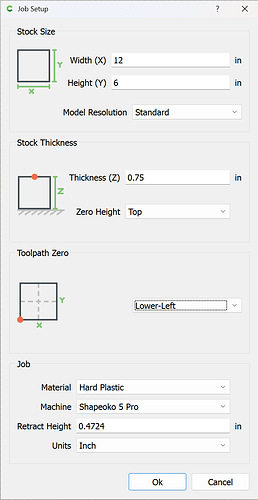

go into Job Setup:

Ok

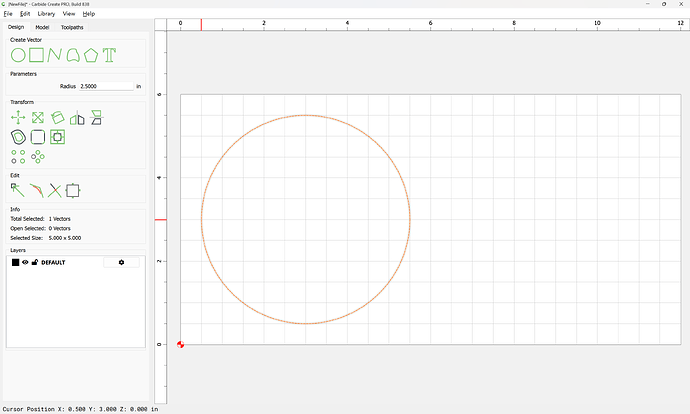

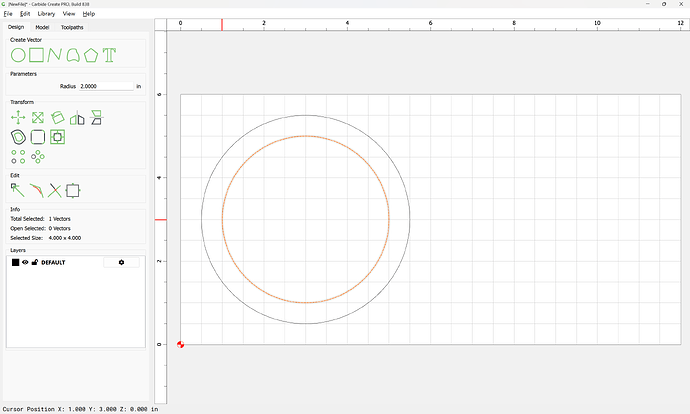

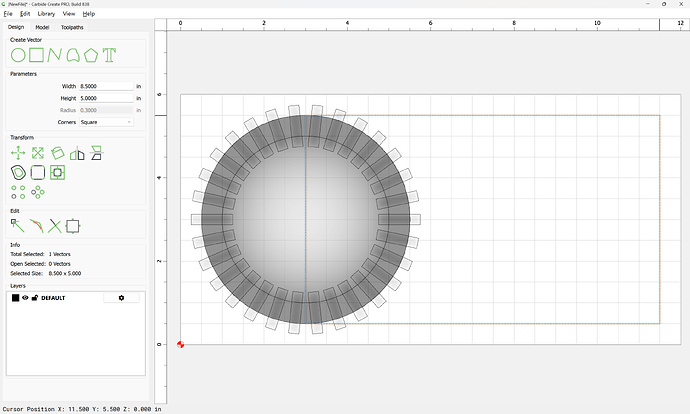

Draw a circle for the overall shape:

and an inner circle:

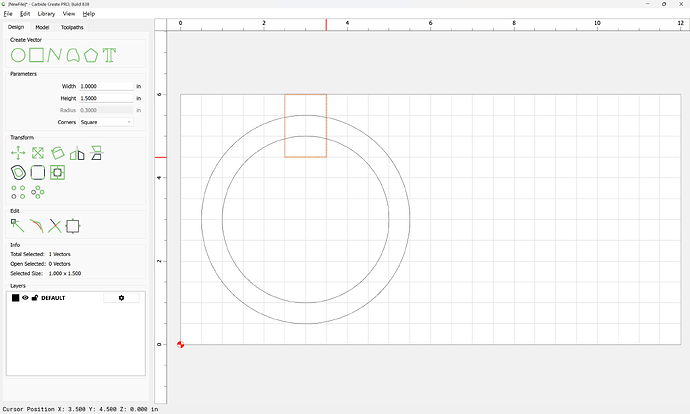

Then draw a rectangle for making an indentation:

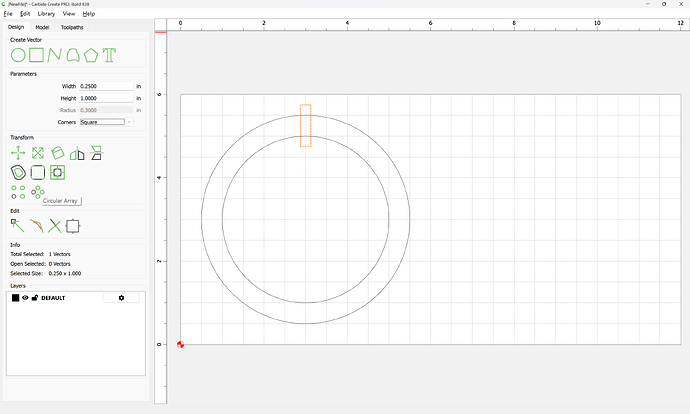

adjusting the size:

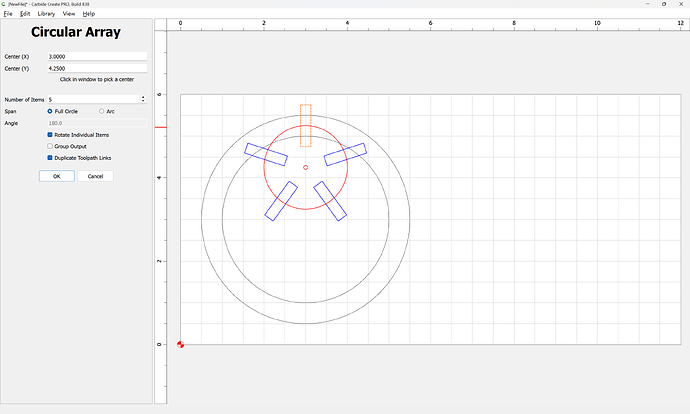

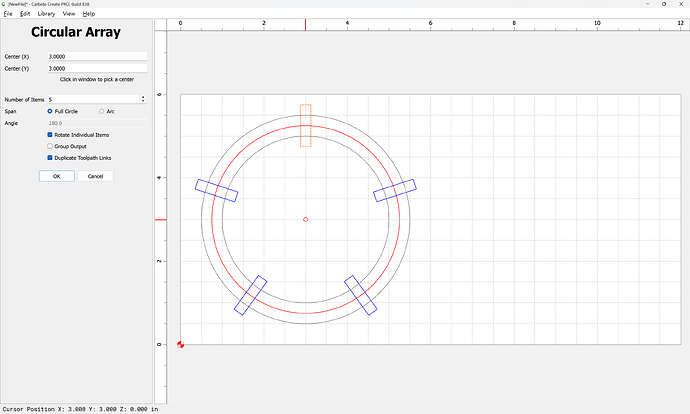

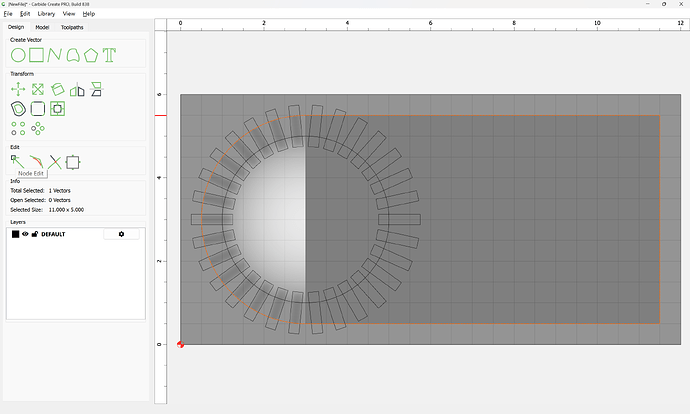

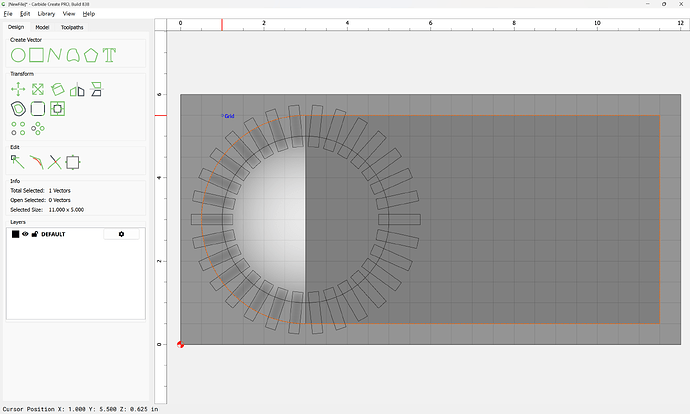

and then use Circular Array to duplicate it around the edge:

Drag the center into position:

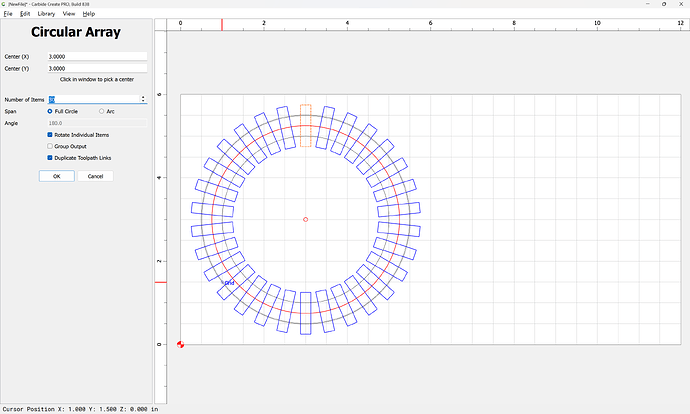

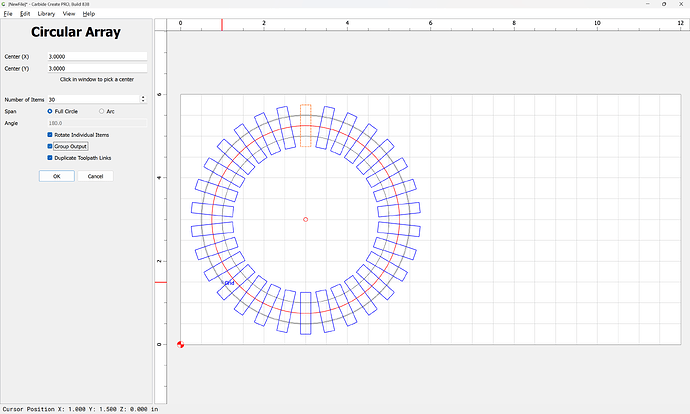

and then adjust the number:

Group Output

OK

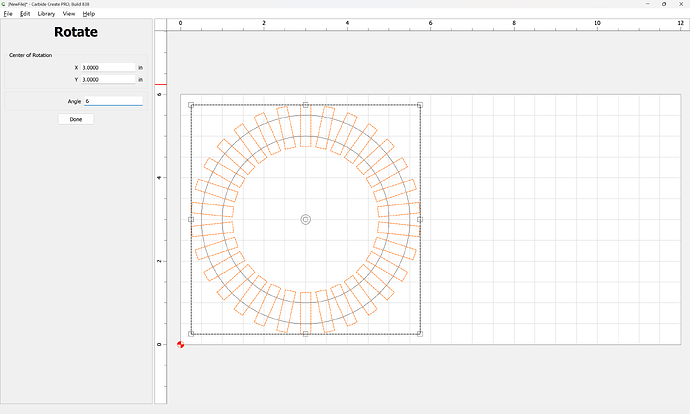

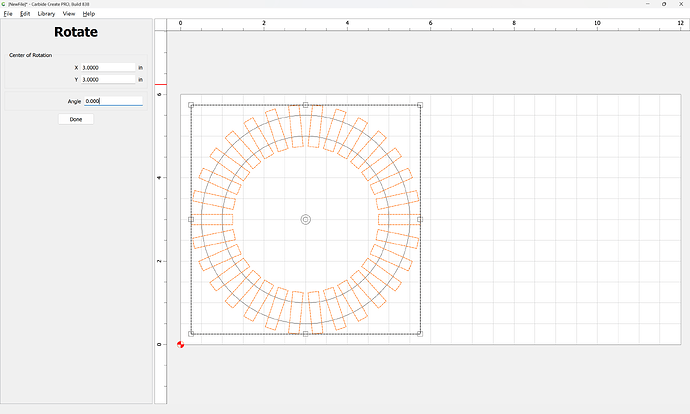

then rotate a bit:

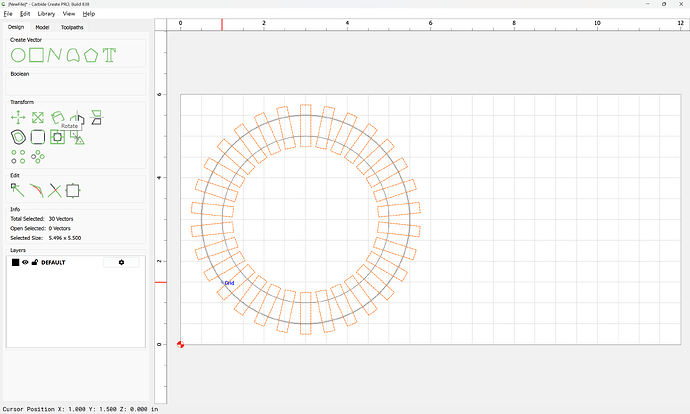

Done

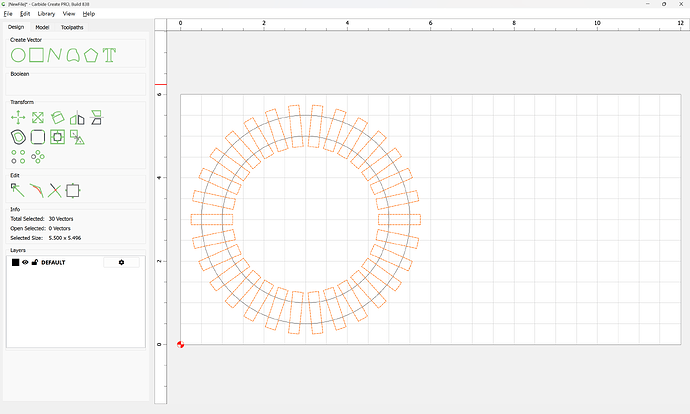

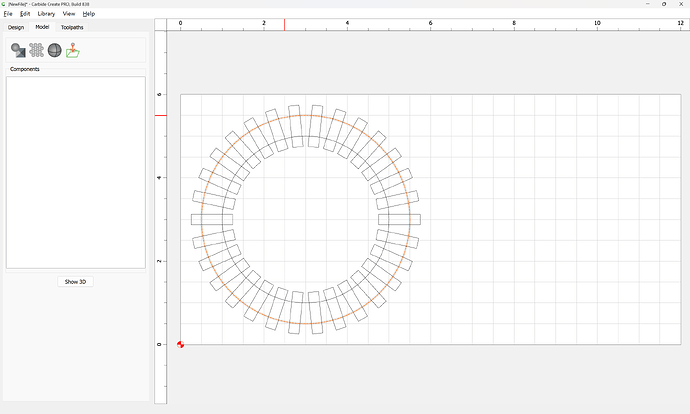

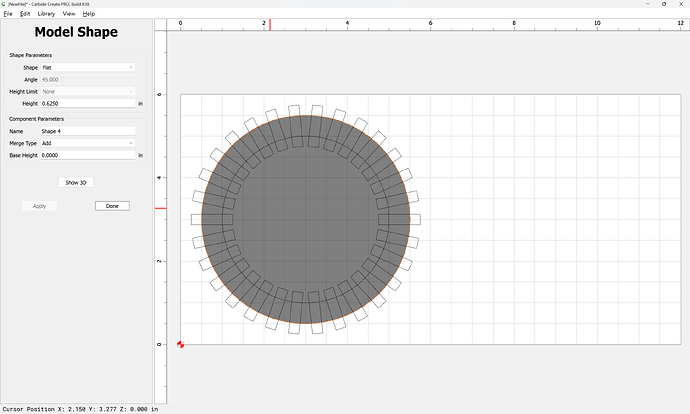

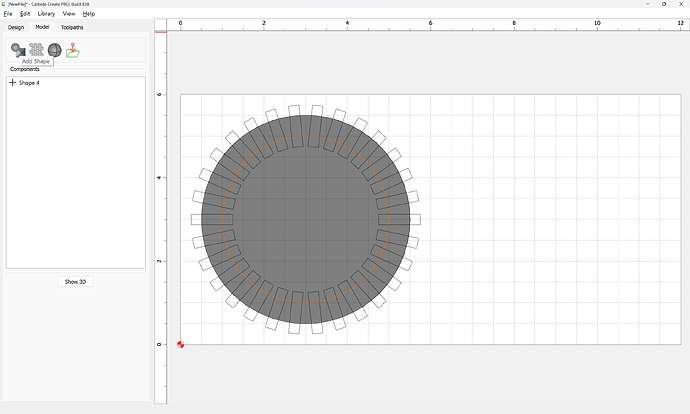

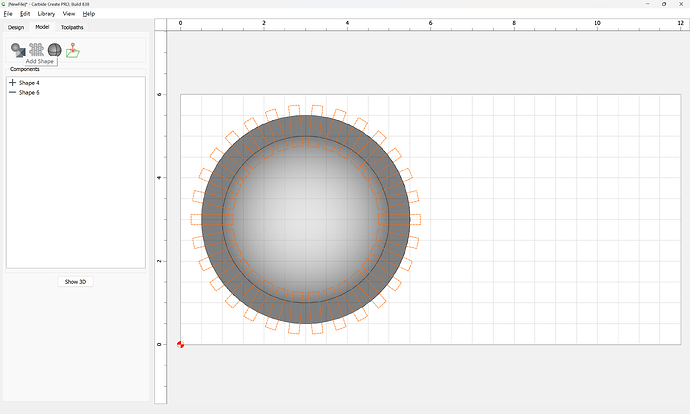

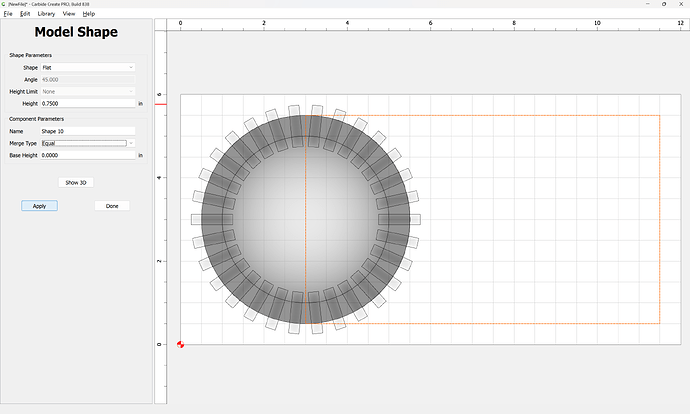

then go to 3D modeling:

select the circle and model it:

Apply

Done

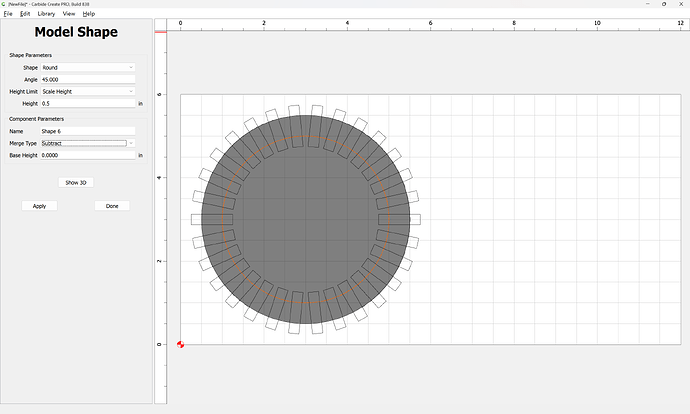

Select the inner circle:

and subtract it:

Done

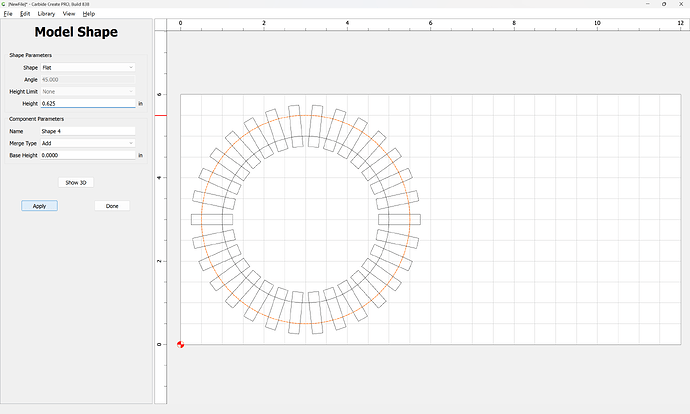

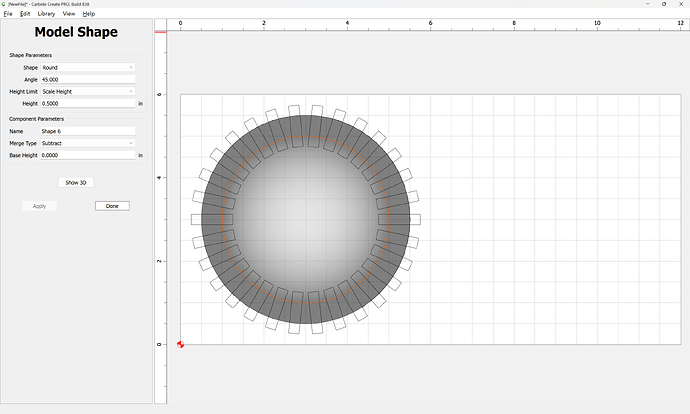

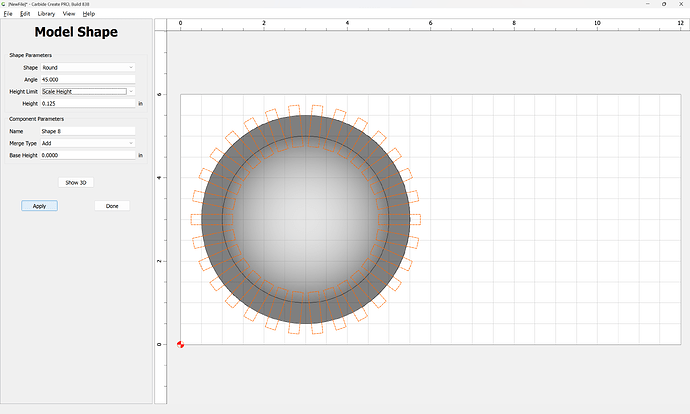

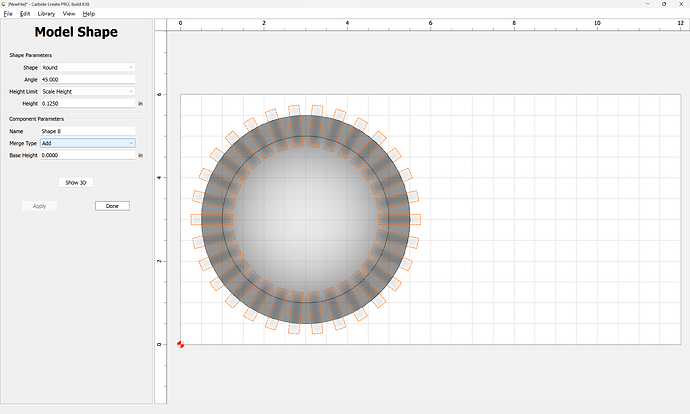

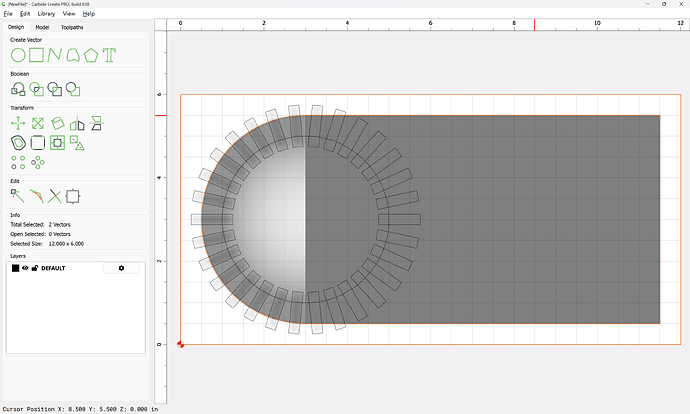

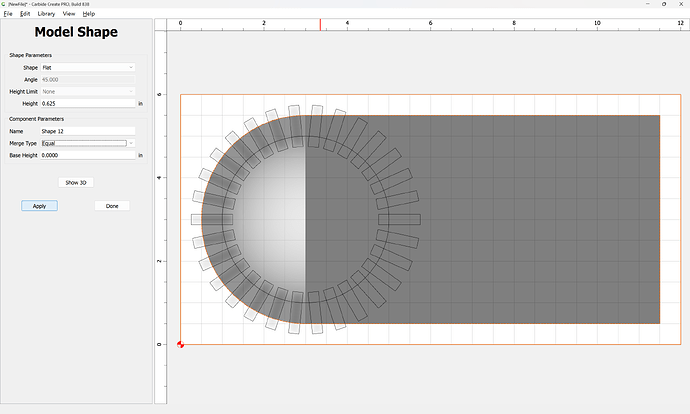

Select the small rectangles:

and model them to create the edge/indentations:

Apply

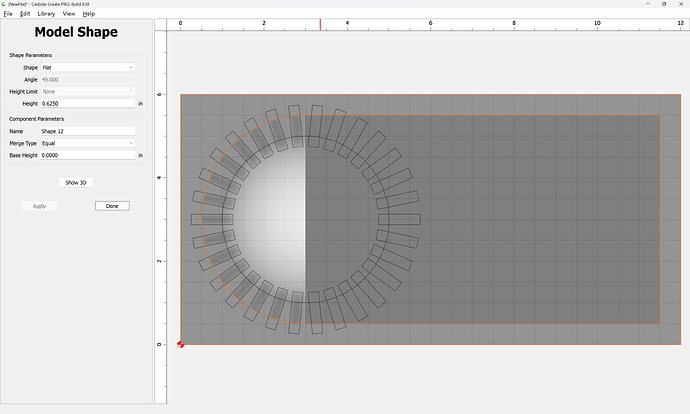

Done

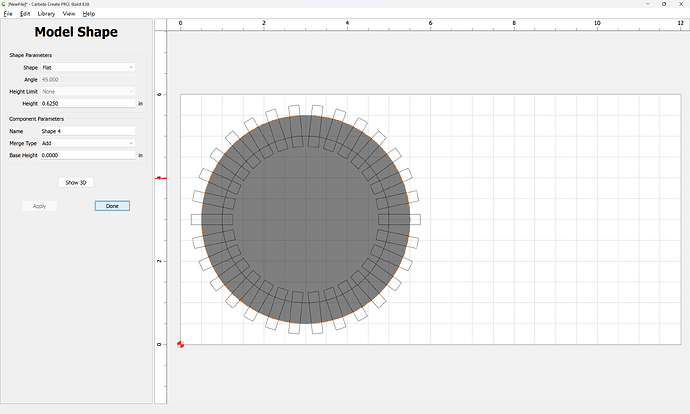

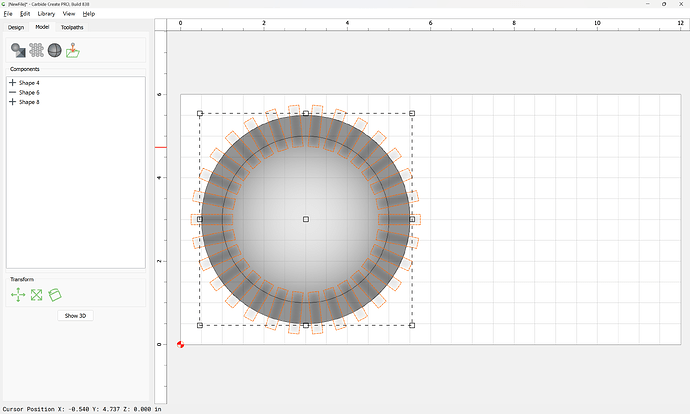

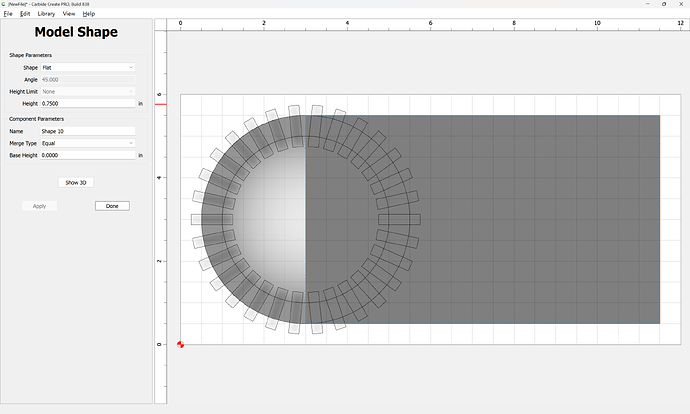

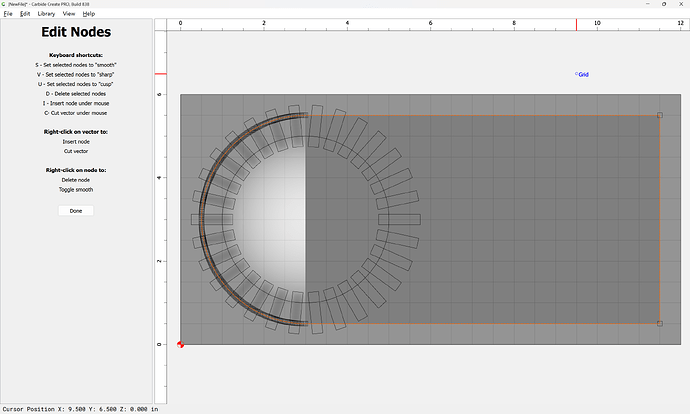

Draw in a rectangle for the flat portion:

and model it:

Apply

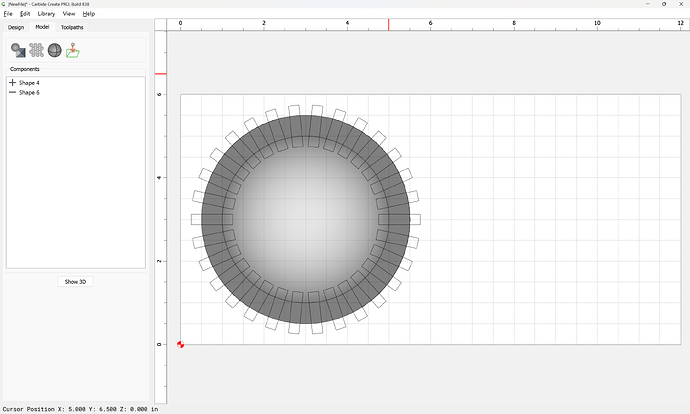

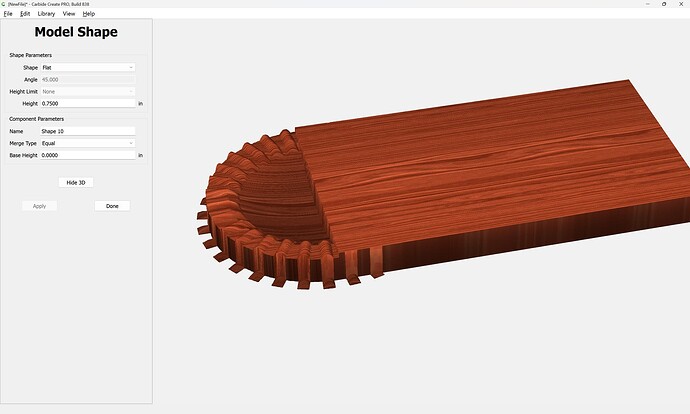

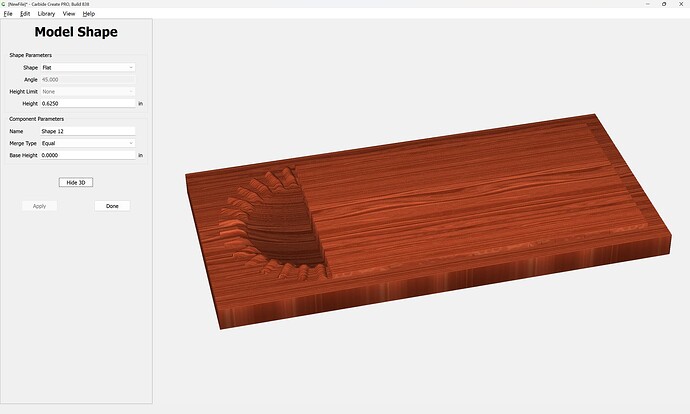

Show 3D:

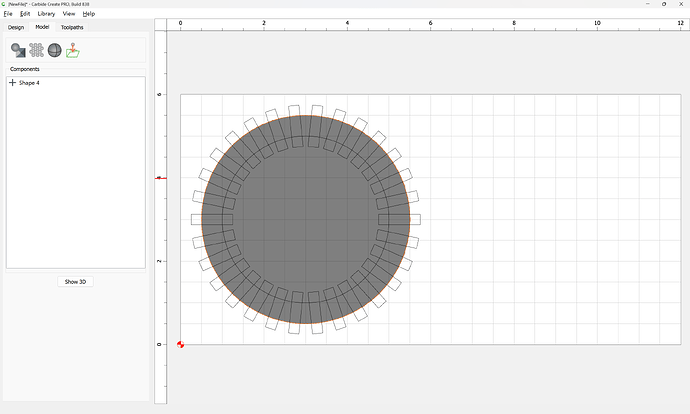

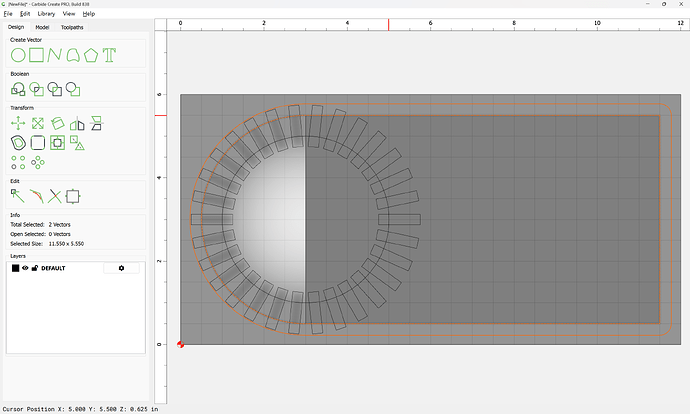

To clean up the edges:

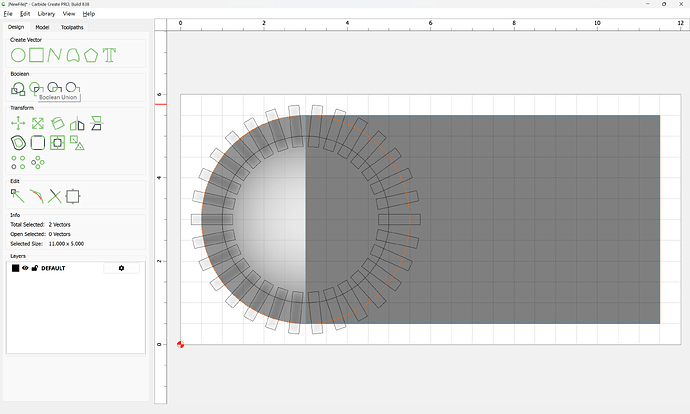

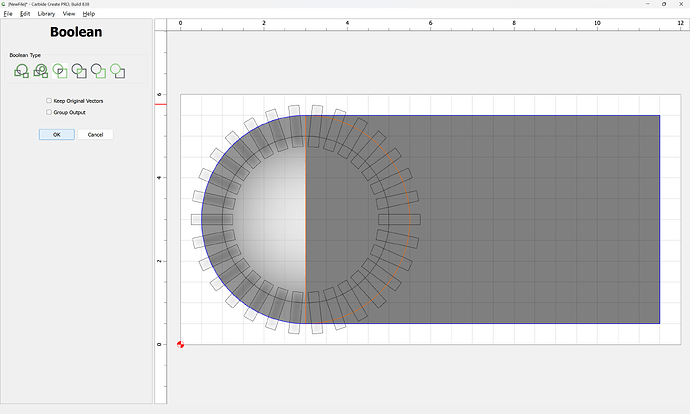

Boolean union the two outer shapes:

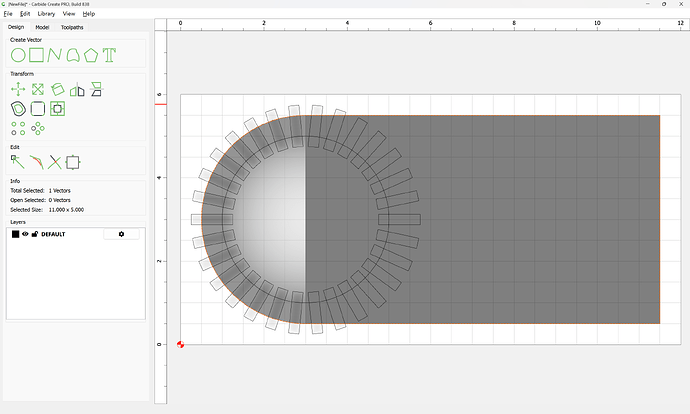

OK

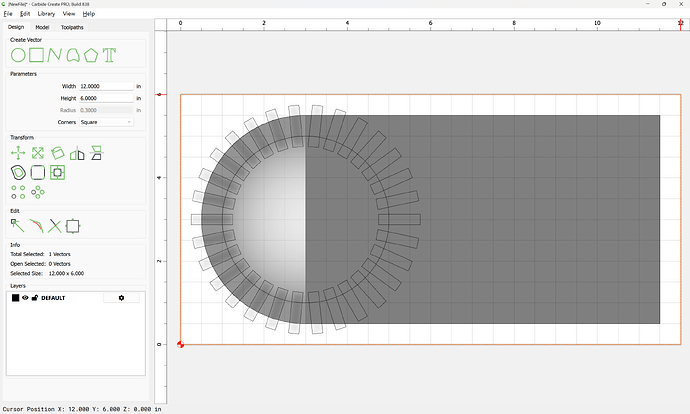

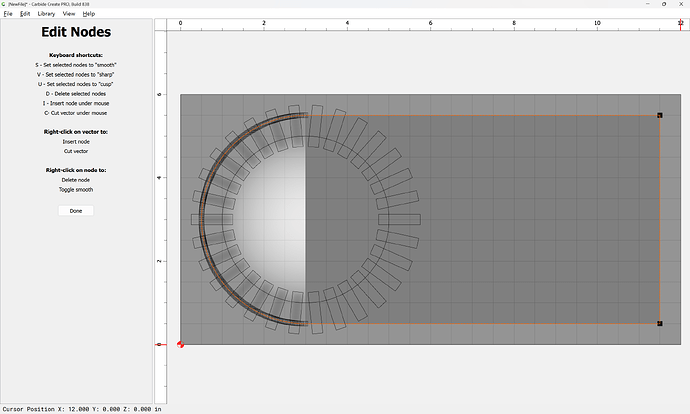

Draw in the stock:

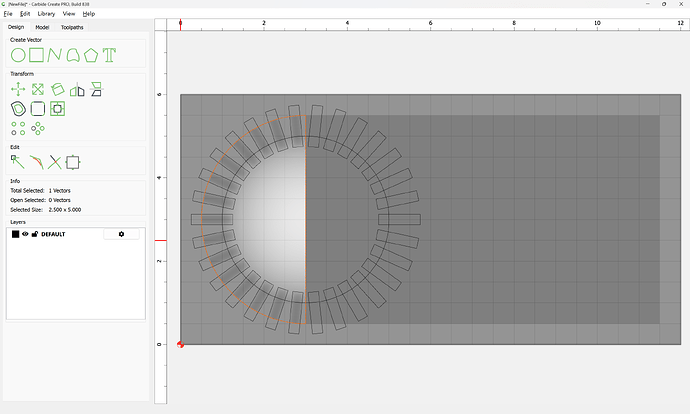

Select the geometries which define the surround:

Apply

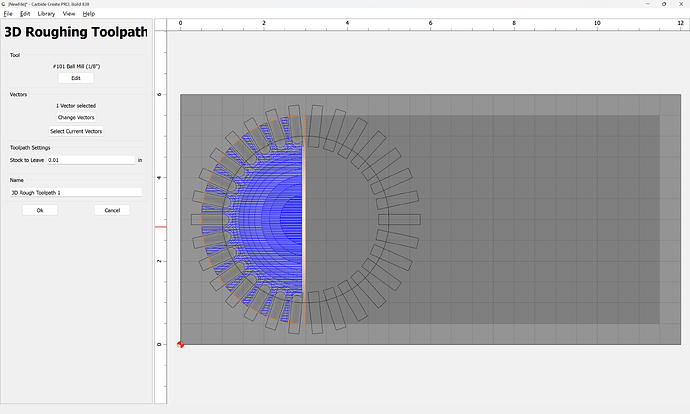

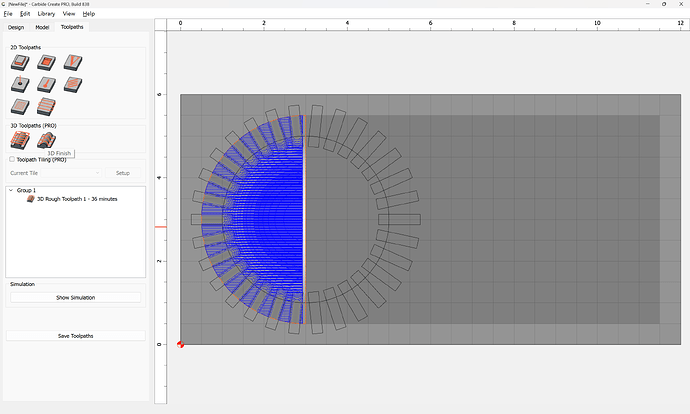

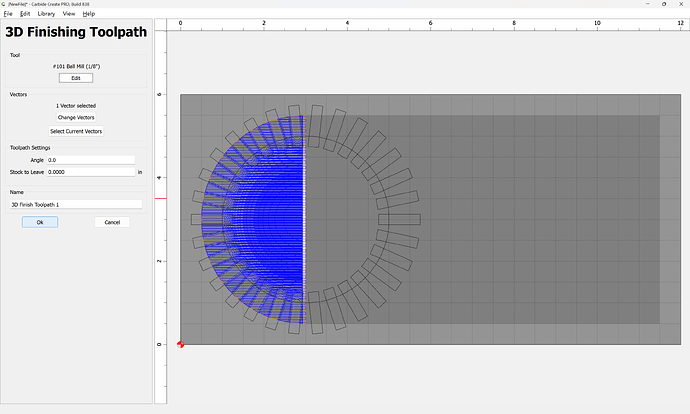

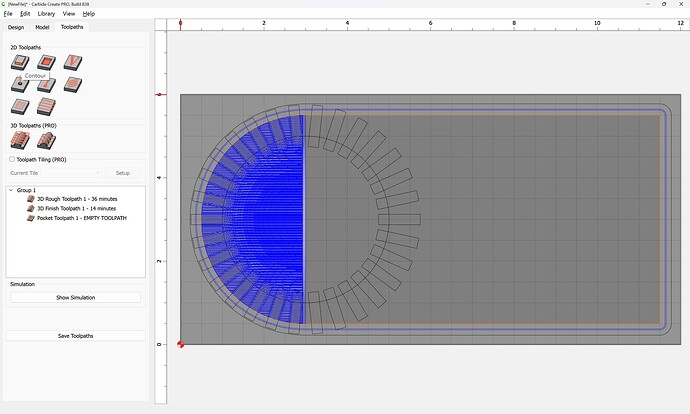

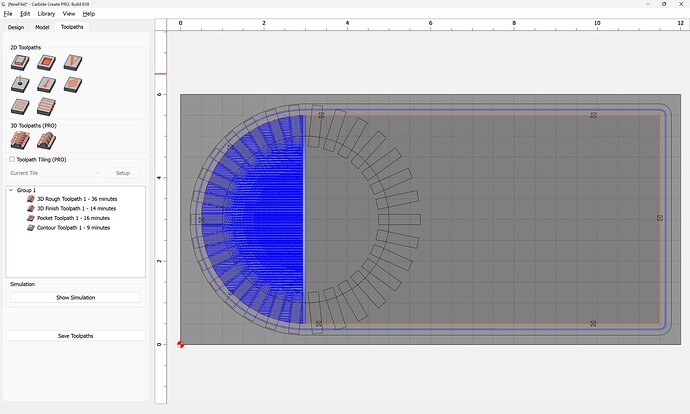

Then set up 3D toolpaths to cut the model:

d (for delete)

Done

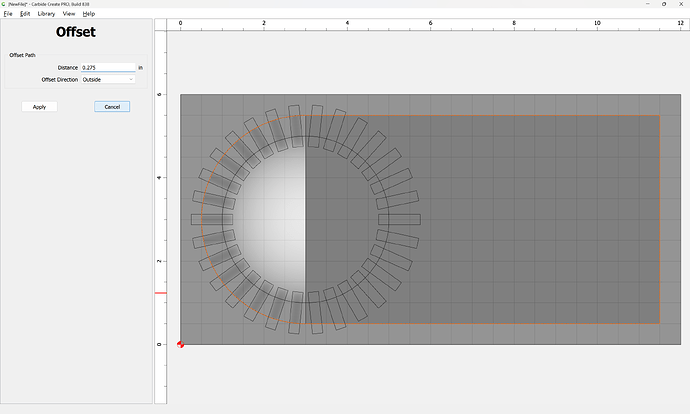

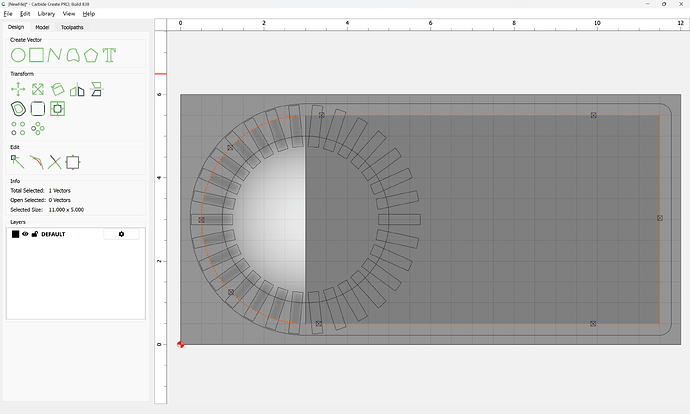

then recreate the outer geometry:

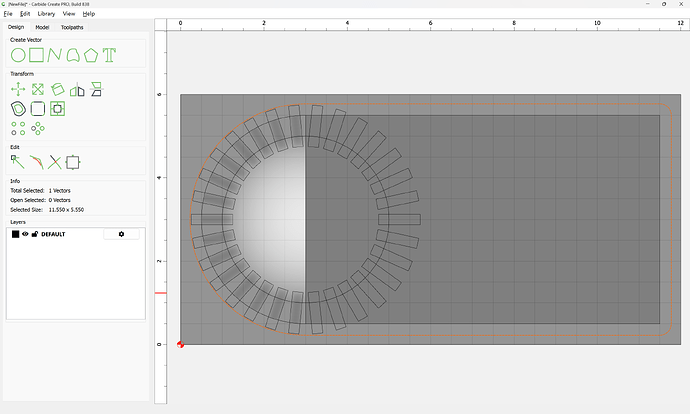

offset to the outside by endmill diameter plus 10%

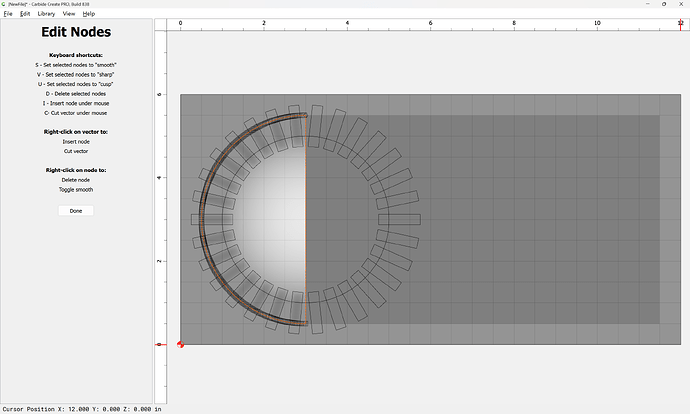

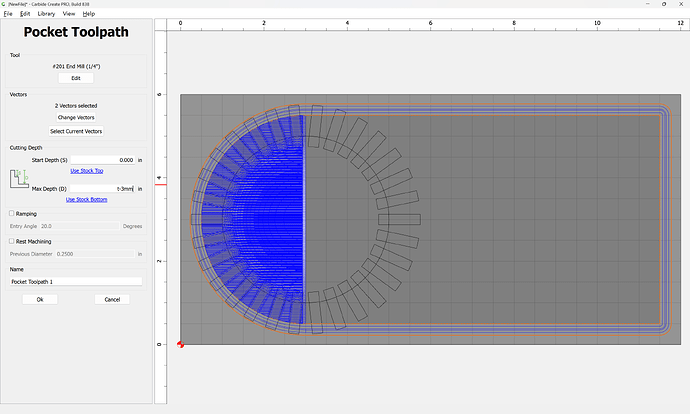

Select both:

and cut as a pocket down to tab height:

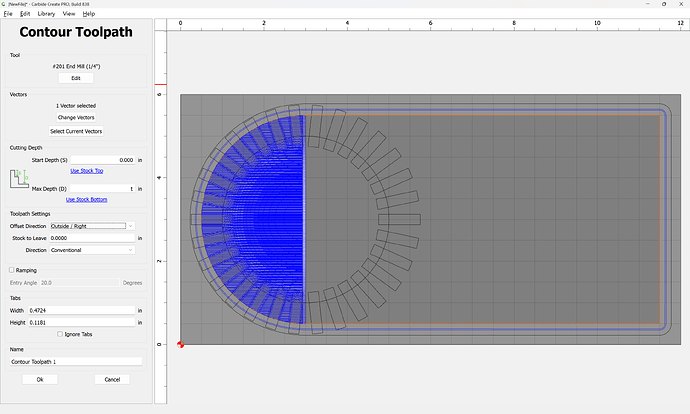

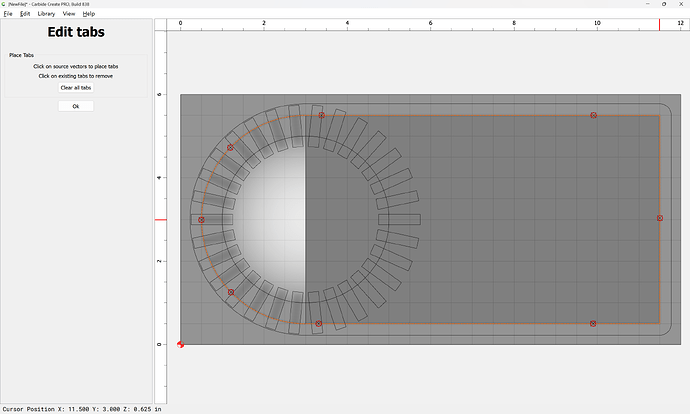

Then apply a Contour around the edge:

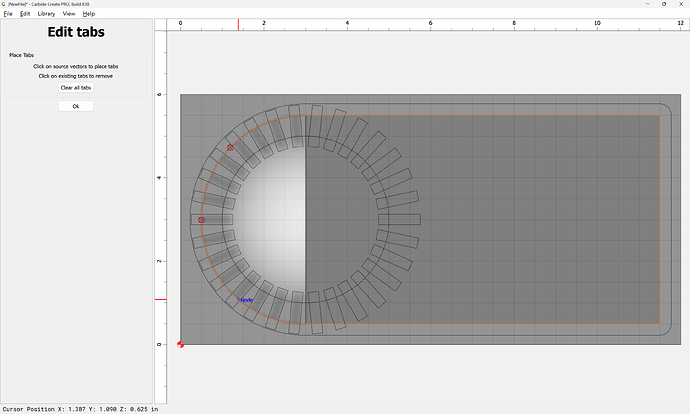

and add tabs:

Ok

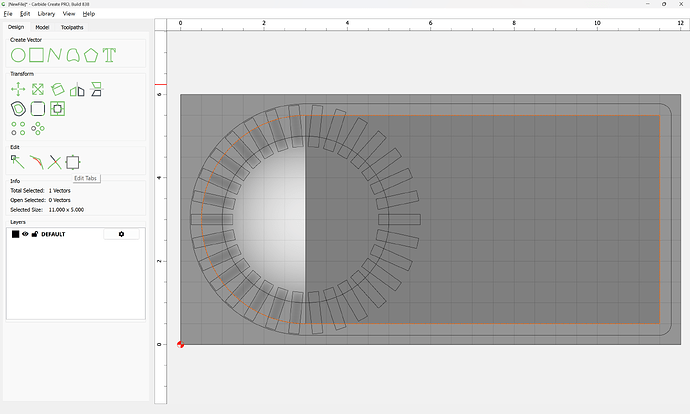

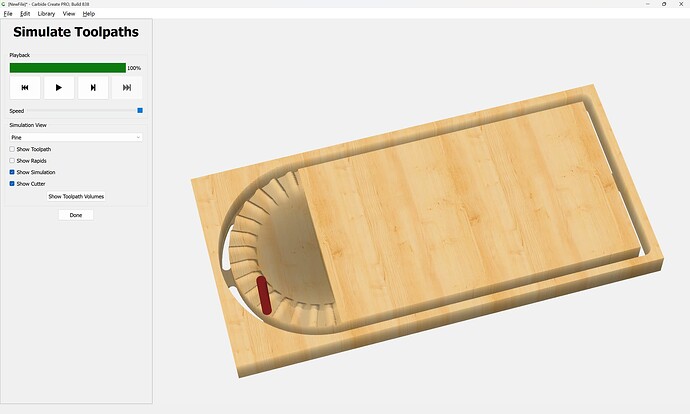

which all previews as: