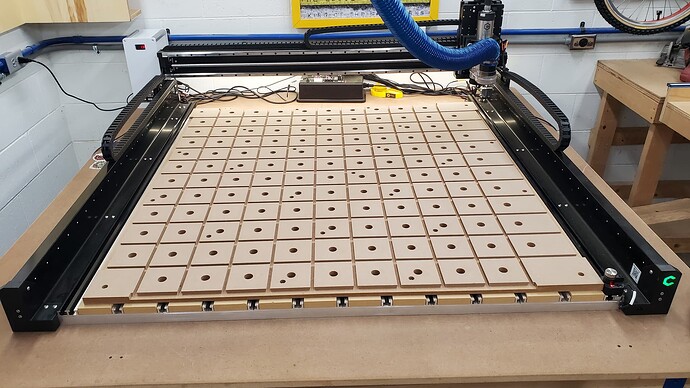

Just finish cutting it this evening. Designed with inserts in the stock base and M6 hardware fasteners. Now the fun begins!

I have been integrating the MatchFit dovetail system in my shop. I have made a plywood setup that is as long as my tablesaw fence and 10" wide to use as a tapering jig and a way to put a straight edge on crooked boards. So far I am liking the MatchFit system. I have also made a 20" x 40" grid to use on top of my bench to clamp down things. I have a Jessem Pocket Mill Pro with their workstation that had the MatchFit system integrated in.

Microjig has introduced a lot of products specifically for CNC machines.

So far I am liking the MatchFit system.

Let us know how you like using the system. I see you have a larger hole in the center of each grid on your spoilboard. On the MFT tables they use that to put a clamp through and hold things. How are you going to use the dog holes?

I have several shop projects planned with the MF system. I think being able to do workholding with less hardware involved (inserts, tracks, etc) is a smart design.

I put the dog holes in which while similar to MicroJig’s design is not designed (currently) to fit their hardware. I’m using the holes as locations for my PVC dowels. If MicroJig comes out with improved workholding specifically for the CNC I could always redesign the holes sizes to match.

I left the corners blank, especially the front left which I will mount L brackets to as another option. Just for fun I plan to carve my new business logo into the right front corner.

After I test it for a bit I will upload the files to Cut Rocket if anyone’s interested. I figured this is version 1.0 for me. Being new to this segment of woodworking I’m always up for improving a design.

When I started back in 2019 I typically used top of material. As time went by I started using bottom of material for about 90% of my projects. The main benefit is my spoilboard does not get cut up like it did when I used top of material.

With the dovetails cutting into your spoilboard might weaken the holding power. With using the bottom of material I very seldom cut into my spoilboard. The top of material I would cut into my spoilboard or have an onion skin left on the bottom of the project to remove. As always measurement of your material is critical but it just seemed that using top of material caused me more problems than using bottom of material.

I’m not understanding what you mean. Bottom vs. Top. What is the difference? I’ve already thought about the flattening of the top and there is quite a bit of play between the MicroJig hardware feet and the top of the wedge. I have a good 1/2" of material to flatten before I get down to the top of the foot pad which would then no longer be useful as a clamping tool. So how long will it take to mill thru 1/2" of material? Only someone with a few years of experience would know. So feel free to comment for those who have this knowledge. How often you flatten would depend on volume of projects and/or how deep past the bottom you cut.