When I load a new job in CM, I often find that I also have to load the C2D file into CC in order to get the details of the job, like it’s starting point, dimensions of the design, etc. I’ve started to try to solve this by convention, by including the basic info in the title of the files, but there’s actually a lot of info that would be helpful to know at cut time, and it’s really cumbersome to include it all.

Request:

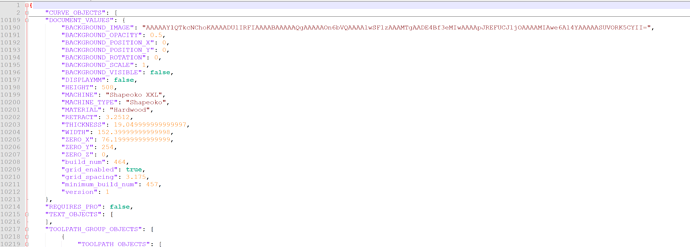

Have the design programs save info (either buried in the GCode - if there’s a place for it - or in a “Carbide Sidecar” file) that carries the basic design attributes to be viewable when you load the Job into CM. It would be great to have a button in CM that pops up a dialog that displays (read only) the info, such as:

- Dimensions of the stock (Width, Height, and Thickness )

- Dimension Orientation (Top, bottom)

- Toolpath Zero location (Center, bottom left, etc.)

- Machine

- Retract Height

- Material

- A free-text Comment field that the designer can use to put any info they’d like to tell the operator

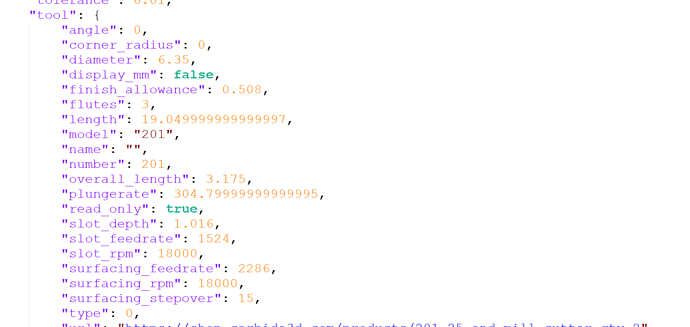

Once you’ve established the mechanism to pass the info between the programs, the sky’s the limit. The display could also show a list of the tools (in order) that will be used by the GCode, so the user can prep for that when they start to load, or show version info, or really anything else the operator might find helpful.

Does anyone else have more info they’d like to see when they load a job?

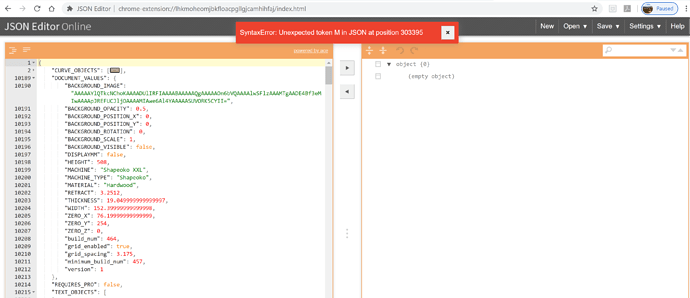

I feel that this makes the Carbide suite more integrated, and helps promote CC and Meshcam as design tools. Meshcam and CC could provide the same file and info (and likely more). The more I think about it, the more a ubiquitous “Carbide Sidecar” file makes sense - CM would only show the info if the sidecar is in the directory with the GCode. If the file format (JSON?) is shared across all Carbide products, it would really serve to integrate your software and make your design tools even more valuable.

Any chance this might be implemented?