I used the 90 degree McEtcher on Acrylic.

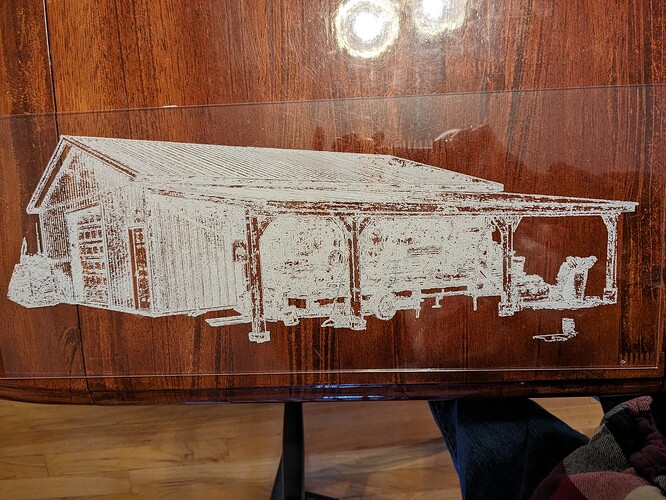

This is what you do not want to do

Content - Have too much detail. The blank areas are just as important as the etched areas.

Image work - I used the Paint.NET → Effects → Ink sketch

Tracing - This is using the standard tracing in InkScape/CC. This will create a path AROUND the pixels.

Cutting

Plow the McEtcher through the material. 2 1/2 turns and .030 deep.

The detail is lost due to over running.

CC - 4.6 million lines of GCode an 15 hrs of actual run time . Ouch

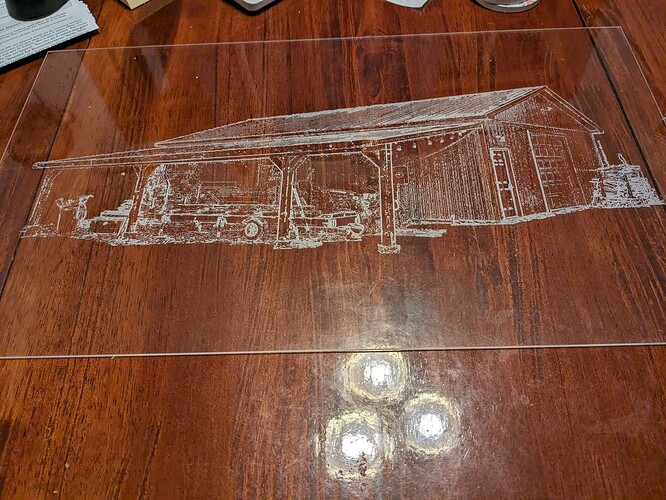

This worked better for me.

Content - Reduced detail by changed Image work and changed Tracing to Center Line

Image work - Paint.NET twice.

- Majority of the content was using Effects → Ink sketch but I allowed detail to be removed.

- Second pass using Artistic → Edge detect ( this created a harder edge only )

Tracing - Inkscape

- Both images were traced in InkScape using the CenterLine option. This creates a single path along the chain of pixels, significantly reducing path generation.

- I saved two SVG files with a box border around the extents so they would align in CC

CC

- I used the McEtcher for the data from the Effects - Ink sketch derived SVG. One turn on the tool and standard settings in CC. 1.6 million lines of gcode. 6 hours of actual runtime.

- I used the #501 engraving tool for the Artistic -Edge detect derived SVG. Standard CC settings at .010 deep

Now to find a edge lighting system.

Note:

The run times for the McEtcher content that CC and CM report are off by a factor of 3.

I set the Feed rate to 100 IPM and the retract to .05 inches .

I watched the Velocity in CM and it never above 33% of the Feed rate setting. I assume this is because of the short path segments, the machine never gets a change to come up to speed.strong text