@FlatBaller, you just beat me to a reply. @TotallyFred, FlatBaller is correct in that you can specify Machine Regions. Set a Machine Region to outline one hole, set all your toolpath parameters and generate the gcode, delete the first Machine Region and define another, generate that gcode, repeat as necessary. It is actually fast to do and I have done it on many occasions.

Another thing to keep in mind is to make sure that waterline finishing is set to Depth First. When MC encounters a deep hole or depression it will stay with that one to the bottom before moving on.

Otherwise it will do a given depth all over the part and skip back and forth a lot.

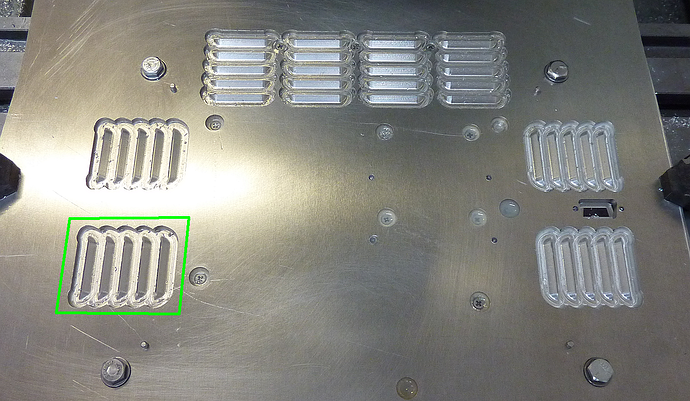

Here is a workpiece where I used the technique, machining one row of louvers at a time

This was for an instrument housing prototype that would ultimately have stamped louvers in it. The actual part is .06" thick with louvers that protrude .125", and I machined the prototype from .187" thick aluminum plate. After I did the louvers themselves, I cleared out the bulk flat area with gcode from SheetCam. I machined the rear side of the louvers using MeshCAM, again row by row, with Depth First chosen also.

Randy