Okay, I apologize for the delay. It took forever** to tram my spindle. But I think it’s good.

Left to right:

Front to back:

This is a little bottle I got from TAP Plastics for dispensing the water thin acrylic solvent. It originally had a blunt needle tip, but that broke off a long time ago. I like it because it can spray a very fine jet of 99% IPA and it doesn’t use a lot, but works great.

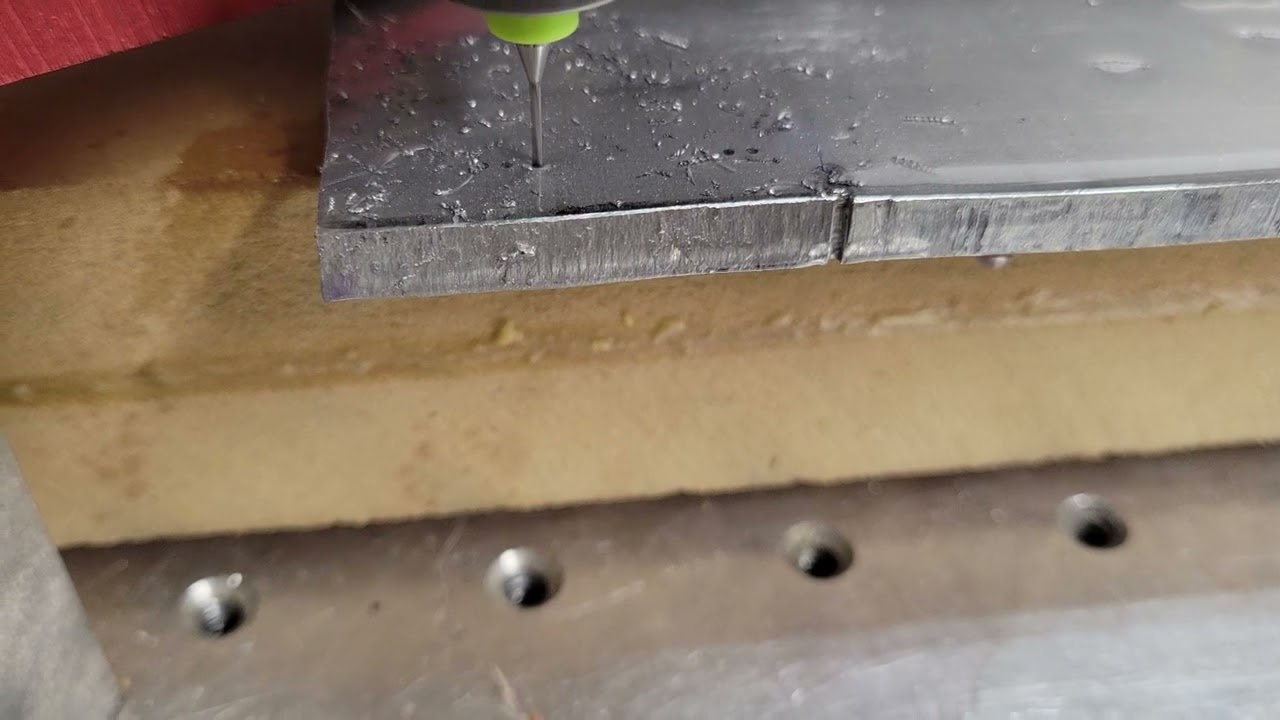

Here is the video of 10 holes being drilled. Turn off your sound! I do not have a drill start, so I just went for it. I have a dial gauge, but not a dial test indicator, so I have not checked my runout yet. A test indicator is on my “to-get” list.

The good news is, it drilled all 10 holes without issue with just the 99% IPA coolant.

RPM: 24K

Peck Depth: 0.010"

Plunge: 10IPM

Total depth: 0.1875"

Online calculator says that is 0.0004IPR

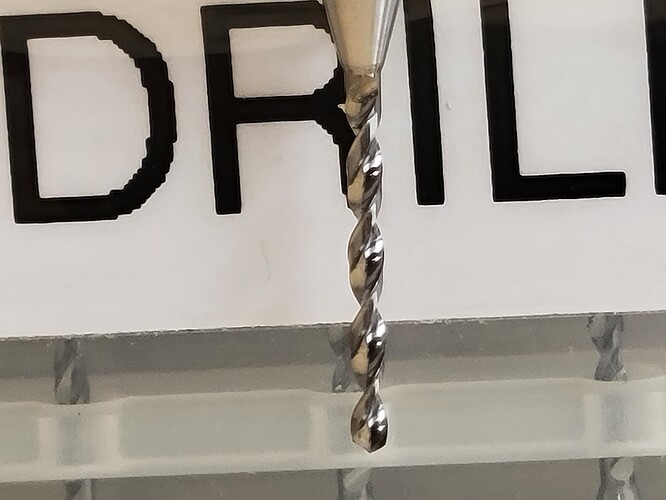

The bit afterwards:

**Forever does not necessarily mean forever, but most likely means an hour and a half or so, because “maff is hard” when putting in shims to calculate angles.