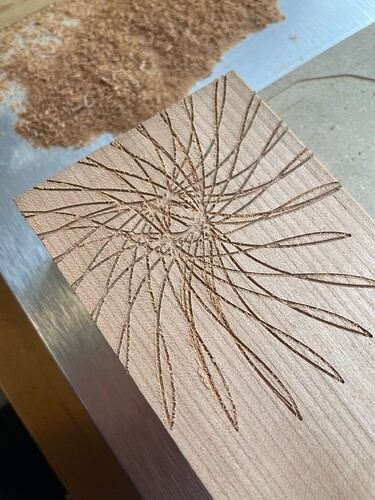

I have been trying to contour cut a thin line with the #121 ballnose .032" end mill into cherry wood. I have tried it twice now and part way through the milling it goes out of alignment and not quite sure why. This is pretty new machine (less than a month old) and this is the only time it’s happened (though I tried it twice and it happened both times). I’m wondering if it is a problem that arises when using this particular and mill as I have never used one so small before.

Where is the bottom left corner in relation to the front of the machine?

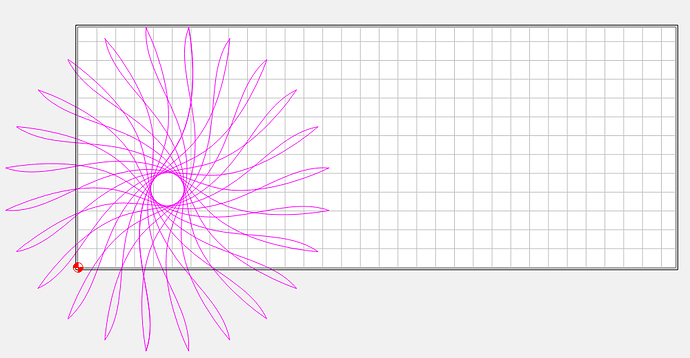

Is the machine able to move all the way to complete the off-stock movement w/o losing steps?

Why not edit the file to eliminate the extraneous movement? If you’ll post it we’ll do a step-by-step walkthrough on how to do so.

If your zero on the machine is near the front left, then the machine may be trying to travel even farther to the left and hitting the left rail, and losing steps.

The bottom left corner is at the front of the machine. It absolutely hadn’t occurred to me the problem was all the extra paths off to the side, I’m sure that’s exactly the problem. Thank you for the tips, that’s really helpful!

oh!! Interesting, I hadn’t considered that. Super helpful! I’m going to edit that file and mill again. Thank you!!

This topic was automatically closed after 30 days. New replies are no longer allowed.