Here are the pics.

The font was Copperplate. The cut was a V-carve of .1" deep. I think the cut was too shallow cause I did not get the nice straight edges of the font. I think I try this file one more time.

Here are the pics.

The font was Copperplate. The cut was a V-carve of .1" deep. I think the cut was too shallow cause I did not get the nice straight edges of the font. I think I try this file one more time.

How does that compare with the 3D preview in Carbice Create?

Are you depth-limiting the V carving?

Is allowing it to cut more deeply workable?

Yes I was limiting the depth of the V-carve, but I think if you go too shallow you don’t get the full weight and form of the font. It’s a balancing act between too deep and not deep enough.

The 3D preview is very closed to the actual cut.

Best to just allow it to cut as deeply as it needs to.

You should never limit the depth on a simple vcarve. You get funky results. Always use advanced vcarve if you want to limit depth. You do not have to use a flat end mill to do clearing.

When you limit depth of a simple vcarve you get unexpected results. A simple vcarve goes down the middle of the line until both sides of the line are met with the vee bit. An advanced vcarve goes down each side of the line to the requested depth. If there is any flat areas you can add a flat end mill. If you add a flat end mill for clearing flat areas but the flat areas are not wide enough for the flat end mill that is ignored and only the vee bit will be requested. When doing a simple vcarve always use bottom of material or the “t”. Be sure to look at the preview because wide lines the bit will go as deep as required to touch both sides of the lines and thin material can cut through. The preview would show white if it is going to cut through.

Here is an example of what I am talking. The top text is a simple vcarve tool path with depth limited to .1". The lower text is advanced vcarve limited to .1 depth.

Both are the same font and same size.

Look at the areas I circled and see the advanced vcarve cut the whole letter. The limited depth simple vcarve deformed the letters.

Here is an example of using the “t” (bottom of material) with 6" letters and a simple vcarve. See the white areas forming at the bottom center of most letters. I had the material thickness set at .2".

Yes. what Will says. Especially with text. David, I looked at the previous C2d file you posted and the W is about 1.62 inches wide. Based on this letter in Coppergate with a 90 degree bit, CC needs to cut 0.145 inches deep to accurately reproduce the font when this size. That is really not that deep ( 90 degree bit will tend to be shallow unless the text is huge). With a V carve toolpath, even if you tell it 1 inch maximum depth, CC will only cut as deep as necessary to reproduce the font. I think if your next test cut allows CC to v carve the text as deep as it wants (in this case 0.145 inches) , you will like what you see.

Cheers.

Never say never — you can get some cool effects with it — try combining a depth limited normal V carving w/ an Advanced V carving for a cool engraved effect (though maybe that isn’t enough to justify having this option?)

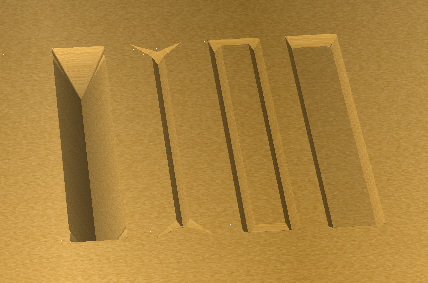

Here’s a synthetic example of what happens if you limit the depth of a VCarve, and the results you get if you instead use Advanced VCarve:

Left to right, each done of the same size rectangle:

If nothing else, when creating a VCarve toolpath, the default value for the depth should always be ‘t’.

Advanced users can change it, but that at least starts the toolpath in the right place.

Man, great information. Thanks. I think I will do a fourth and final version of my sign. Much appreciated.

Since every v carve toolpath has a calculated maximum based on the bit/path combination, I would prefer a default depth of a v carve to be as deep as CC calculates it and it should trigger an alert if the CC calculated depth exceeds stock thickness. Something like, " The calculated V carve depth is XXX and exceeds the stock thickness of YYY. " A further message could alert users to either continue, use material which exceeds XXX in thickness, or reduce the max depth and sacrifice the V carve accuracy. The problem is in program flow. You are prompted for depth before the toolpath is determined but the toolpath must be determined before max depth can be calculated. Maybe you could use a checkbox “use calculated max depth y/n”… The alert would only show after the toolpath was calculated. In this scenario there would actually be no default, just an option to allow CC to determine max.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.