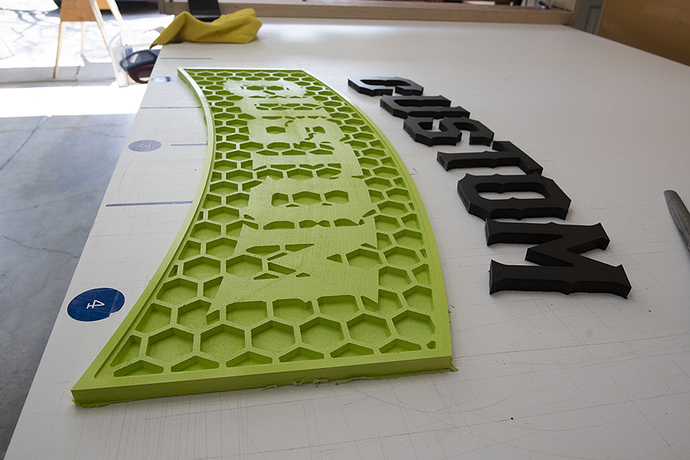

My typical workflow. PVC, rattle can paint.

love your signs I may try to do a few myself

@Dennis, how do you handle all of the static clinging PVC crumbs?

PS. Great way to do a sign!

I do not have any problems with static.

@Dennis

Where do you get this type of PVC from?

Thanks. Great work!

Henry, I get it from my local sign supply. Denco Sales. You can find an online plastics supplier. Comes in 4’ x 8’ sheets.

Very nice!

I saw you in the Signcraft’s magazine with your Death and Taxes, haha!

If you don’t mind, what Bits do you use for cutting PVC Foam like you do?

Henry,

I use O-flute bits. toolstoday.com or amazon. Amana single flute o-flute, and I think I use both upcut and downcut with the same results on PVC. PVC is really soft. My feed rate for PVC is pretty fast, between 60in to 90in. Depth per pass is usually around .125 - .14, plunge is like 65. Very forgiving material.

For cutting letters I outline the letters .05 and do my multiple passes at around .125, then the final cut I come in on the original letter line and do a final full depth pass at whatever my material thickness is to clean up the edge and get rid of the banding from multiple passes. (hope I explained that well)

I got hooked up with Signcraft and have done a couple articles with them. It’s fun and I feel like it keeps me relevant in the sign industry. You can reach me here dennis@stanworthsign.com if you have any questions.

One more thing since we talking. I originally bought the T-Track and I found I was spending a lot of time securing material down. Finally I just removed the track and I just screw directly into the wasteboard. I just replace my wasteboard about every six months. It’s easy to replace and inexpensive and way faster than securing material with clamps. I also use 1/8" PVC spacer scrap material to hold my cutting piece up off the bed so my bed is clean, no cutting into the bed. FYI.

This one and it’s 1/8" counterpart tear through PVC like butter. I just cut a 15mm deep pocket at full depth, 3000mm/min, using adaptive clearing with a 3mm optimal load. Fun stuff to cut.

I use amana O-flute (single flute) bits.

Thank’s for the links! Do you use a Makita/Dewalt precision collet to use these bits? Thanks. I’m considering buying, I just need to know what I should purchase before buying the XXL.